External tire pressure gauge, mounting structure thereof and corresponding dismounting tool

A technology for installing structures and loading and unloading tools, which is applied in hand-held tools, manufacturing tools, tire measurement, etc. It can solve the problems of small screw size, inconvenient operation of screws, inconvenient screw alignment with screw holes, etc., and achieve the effect of fastening the connection relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

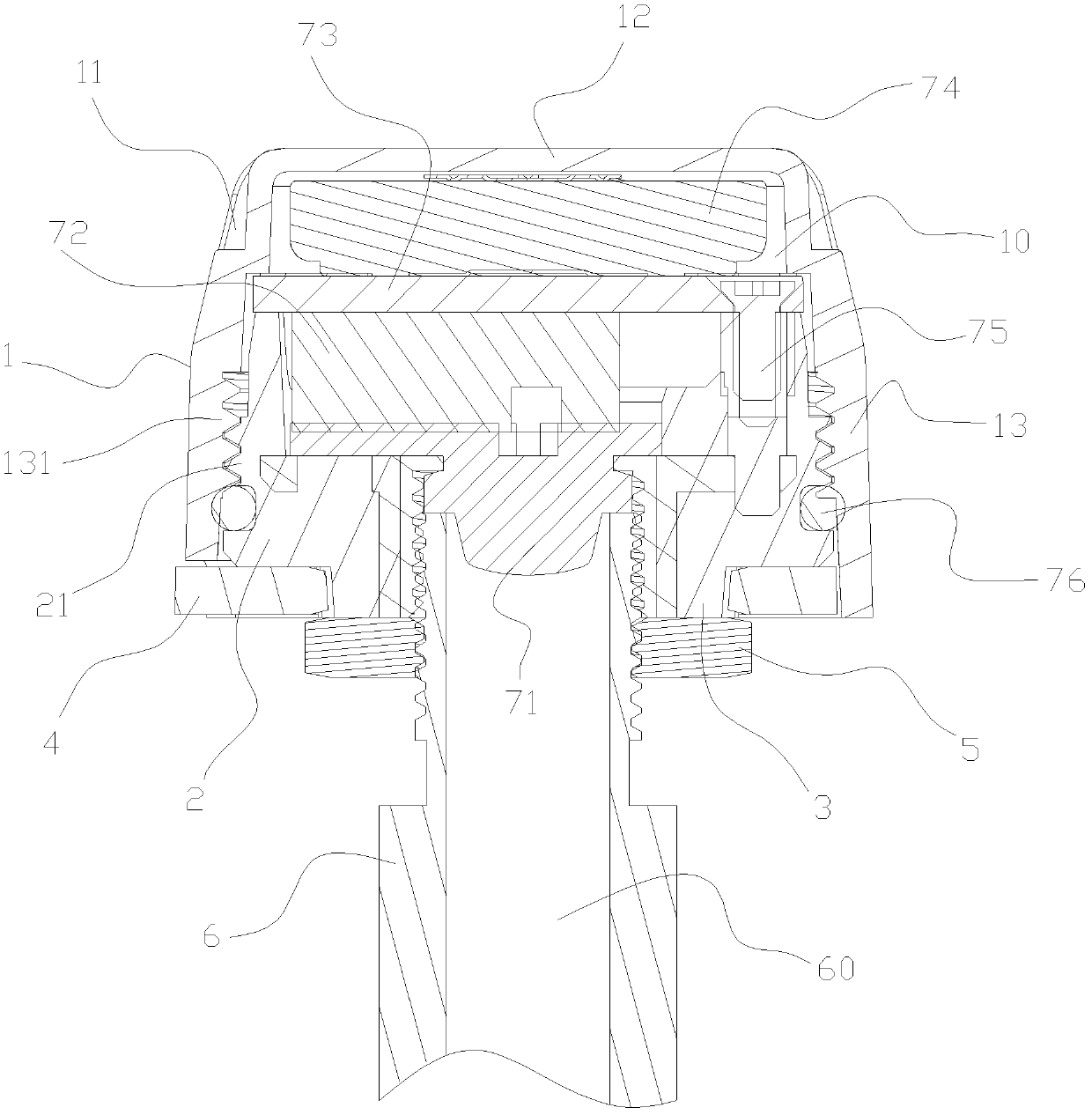

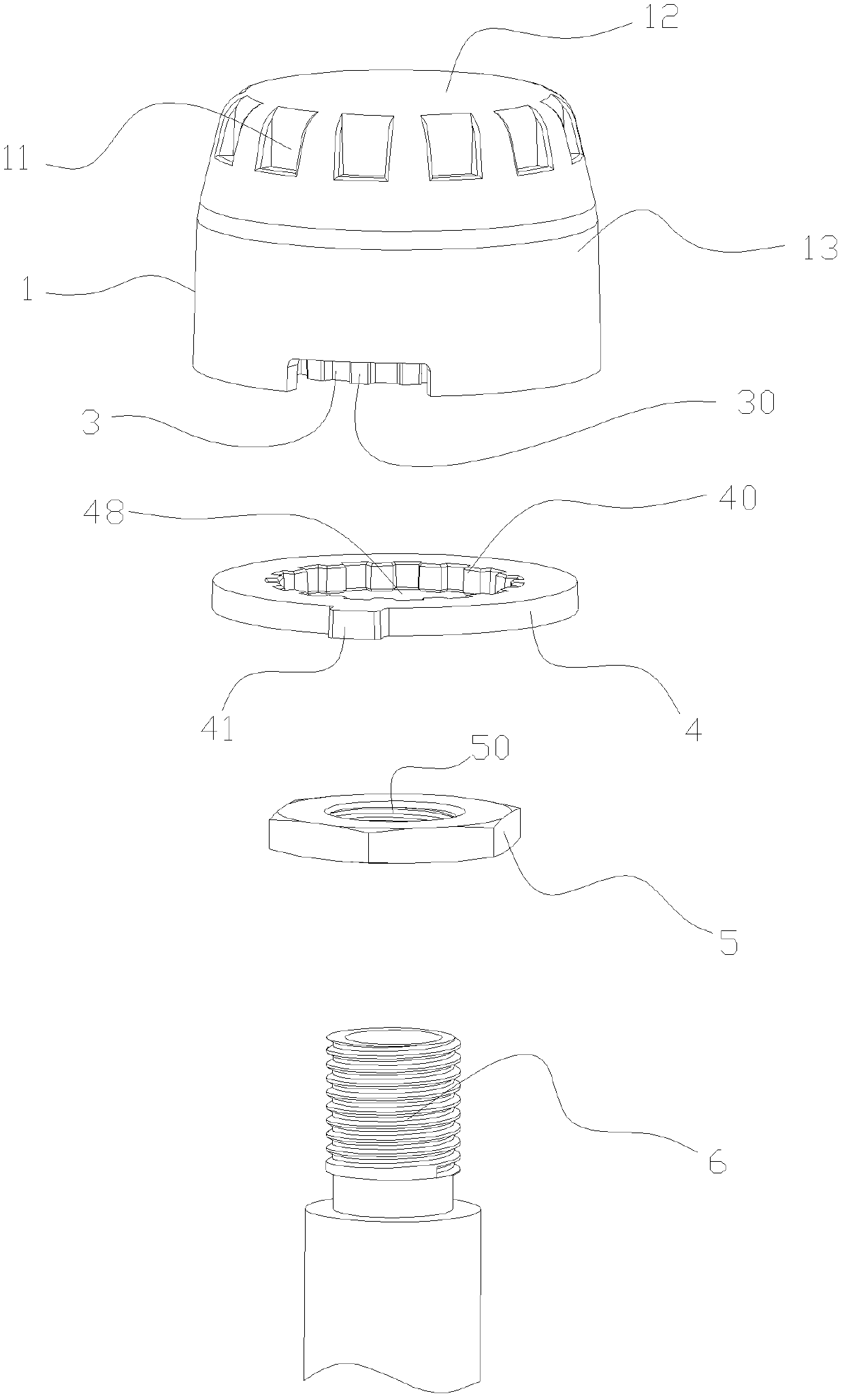

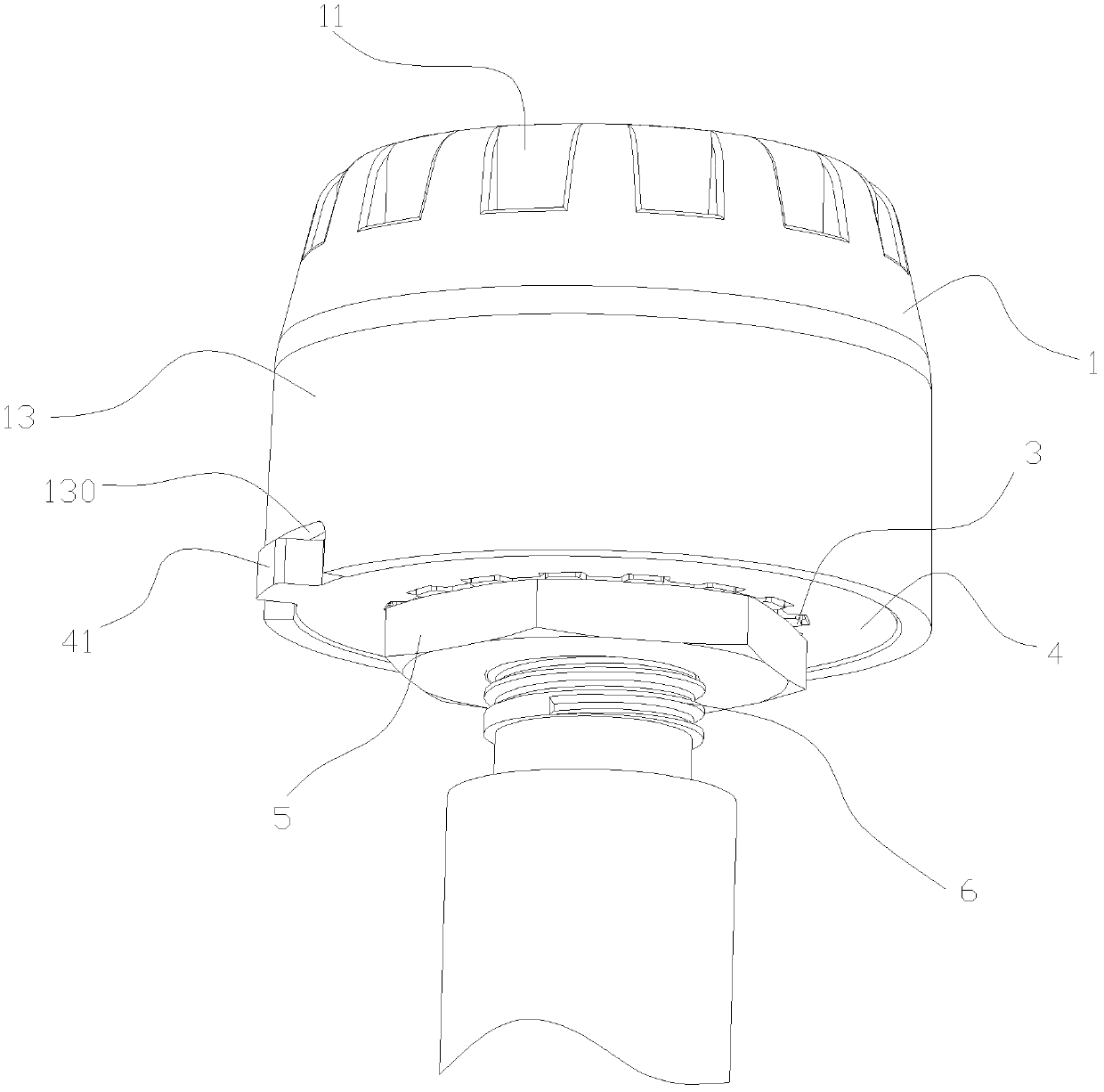

[0039] see figure 1, the external tire pressure gauge of the present invention is installed on the valve stem 6 of the tire of the vehicle, and the valve on the valve stem 6 is pushed open by a push rod 71, so that the pressure inside the tire is transmitted to the tire pressure gauge The internal pressure sensor 72 enables the sensor 72 to measure the current tire internal pressure, and transmits a signal representing the pressure into the air through a corresponding control circuit (not shown) and an antenna 75, so as to be detected by the monitoring unit (not shown) in the car. Figure) receiving processing, so as to complete the detection of car tire pressure.

[0040] refer to figure 1 , the external tire pressure gauge of the present invention provides an installation structure with an internal installation space 10, a pressure sensor 72, a circuit boa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com