Patents

Literature

32results about How to "Large brushing area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Marine organism shell powder paint

ActiveCN102167936AImprove finenessHigh whitenessAlginic acid coatingsHyaluronic acid coatingsCitric Acid MonohydrateCitric acid

The invention provides a type of marine organism shell powder paint, mainly comprising biosynthesis adhesive, sodium hexametaphosphate, shell powder, emulsifier, and citric acid mono. The marine organism shell powder paint is purely natural, environment-friendly, of simple preparation and of low manufacturing cost, and has no toxic effects on human body.

Owner:青岛万源生物科技有限公司

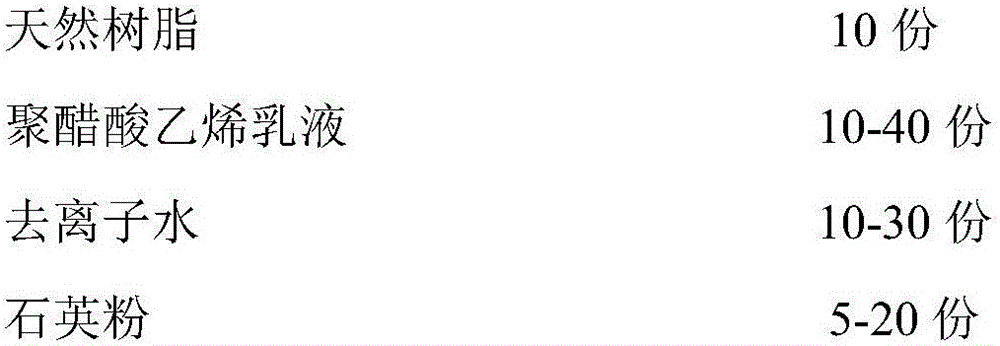

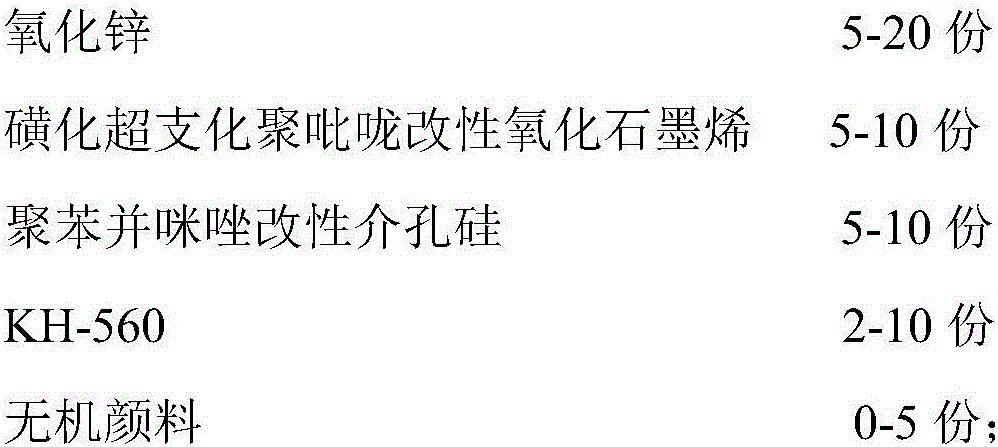

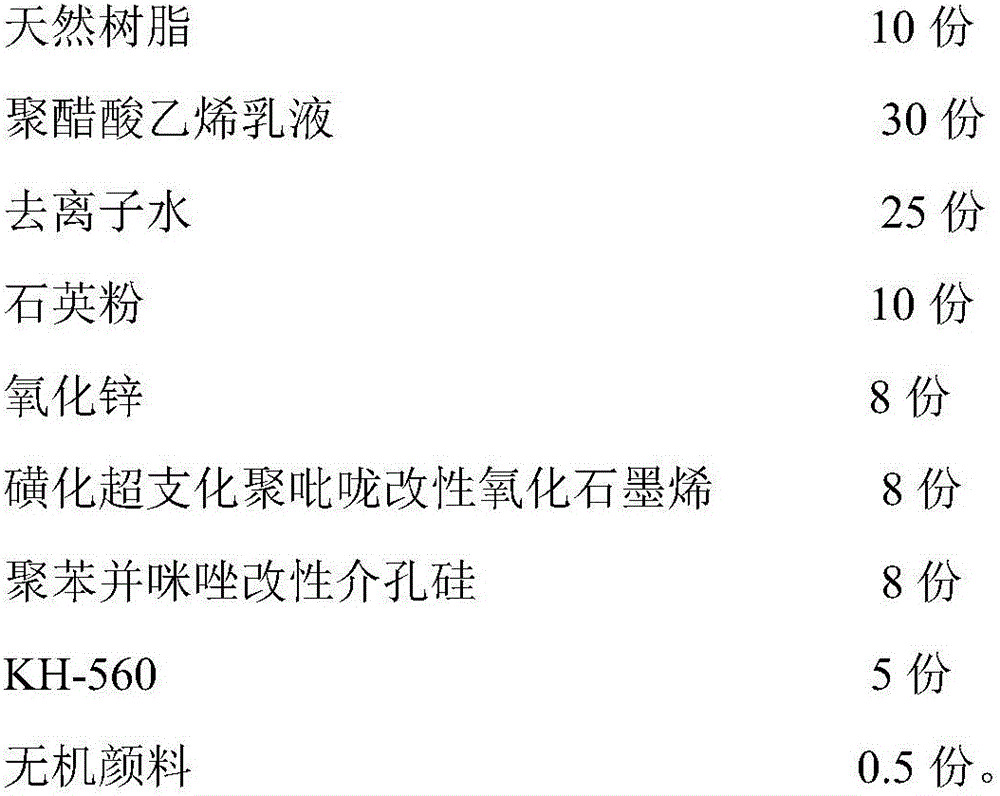

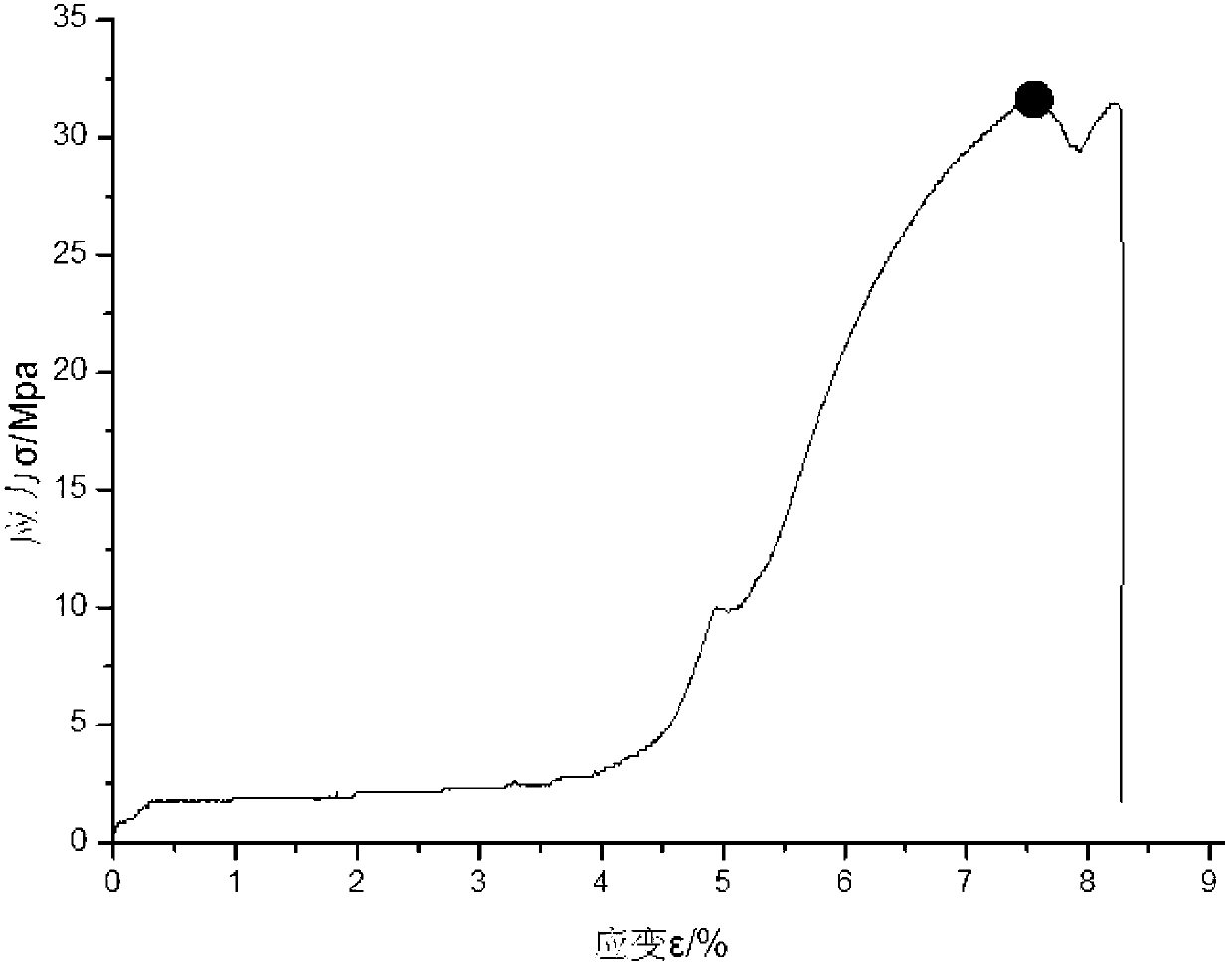

Exterior wall coating material capable of finishing working through one-time painting

ActiveCN105754431AGood stabilityGood alkali resistanceNatural resin coatingsRosin coatingsEmulsionOxide

The invention discloses an exterior wall coating material capable of finishing working through one-time painting.The exterior wall coating material is prepared from natural resin, polyvinyl acetate emulsion, deionized water, quartz powder, zinc oxide, sulfonated hyperbranched polypyrrolone modified graphene oxide, polybenzimidazole modified meso-porous silicon, KH-560 and inorganic pigment.The exterior wall coating material capable of finishing working through one-time painting has the better adhesive capacity, aging resistance, covering power, washing resistance, scratching resistance, stain resistance, self-cleaning performance, fastness, acid resistance and alkali resistance, longer service life and the like compared with existing water-based exterior wall coating materials.

Owner:JIANGXI LONGZHENG SCI & TECH DEV

SBS universal glue and preparation thereof

The invention discloses SBS universal glue, which is prepared from the following raw materials by mass portion: 60 to 65 portions of environment-friendly solvent, 15 to 20 portions of SBS, 3 to 6 portions of terpine resin, 3 to 6 portions of petroleum resin, 4 to 7 portions of rosin, 1 to 3 portions of filling, 1 to 3 portions of antifreeze agent, and 1 to 3 portions of age inhibitor. The SBS universal glue prepared by a process has the characteristics of large painting area, environmental protection, high solid content, strong initial adhesion, transparence and good smell, so the SBS universal glue can be widely used in adhesion of an aluminum plastic panel, a fire-proof plate, wood skin, a wood board, and the like.

Owner:SHANDONG EVERGAIN ADHESIVE CO LTD

Paste solder for hard soldering of SiCp/Al composite material and preparation method and use method thereof

InactiveCN103100800AReduce in quantityImprove automationWelding/cutting media/materialsSoldering mediaAdhesiveTubing types

The invention relates to a paste solder for the hard soldering of a SiCp / Al composite material and a preparation method and use method thereof, and relates to a solder for the hard soldering of the SiCp / Al composite material and a preparation method and use method thereof. The paste solder for the hard soldering of the SiCp / Al composite material aims at the problem that the traditional strip-shaped solder or foil-shaped solder is adverse to the automation in a hard soldering process and is not suitable to weld an irregular, small-sized or geometrical complicated part. The paste solder for the hard soldering of the SiCp / Al composite material is prepared by mixing solder alloy powder, a soldering flux and an adhesive. The preparation method comprises the following steps of: 1, preparing the solder alloy powder; 2, preparing the soldering flux; 3, preparing the adhesive; and 4, mixing to prepare the hard soldering of the paste solder for the SiCp / Al composite material. The use method comprises the following steps of: adopting coating type cloth or needle tube type cloth; and then carrying out vacuum heating treatment so as to complete welding. The preparation method disclosed by the invention is mainly used for preparing the paste solder for the hard soldering of the SiCp / Al composite material.

Owner:HENAN POLYTECHNIC UNIV +2

Environmental-friendly waterborne coating for building inner wall decoration and preparation process of environmental-friendly waterborne coating

InactiveCN104263155AGood coating performanceReduce the content of harmful substancesAntifouling/underwater paintsCellulose coatingsCelluloseKaolin clay

The invention discloses an environmental-friendly waterborne coating for building inner wall decoration. The environmental-friendly waterborne coating is prepared from the raw materials in parts by weight: 20-40 parts of deionized water, 0.3-0.5 part of cellulose, 0.5-1.0 part of a wetting dispersant, 0.1-0.3 part of a defoamer, 0.1-0.2 part of a pH regulator, 2-8 parts of titanium dioxide, 5-8 parts of kaolin, 10-15 parts of light calcium carbonate, 5-10 parts of talc, 15-25 parts of heavy calcium carbonate, 8-12 parts of acrylic emulsion, 0.1-0.5 part of a fungicide, 1-2 parts of propanediol, 0.5-1.0 part of a film-forming additive and 0.3-0.5 part of a thickener. The environmental-friendly waterborne coating has the characteristics of good coating effect, low harmful matter content, soft smell, low production cost, good stability and long service life.

Owner:安徽铁创新材料科技有限公司

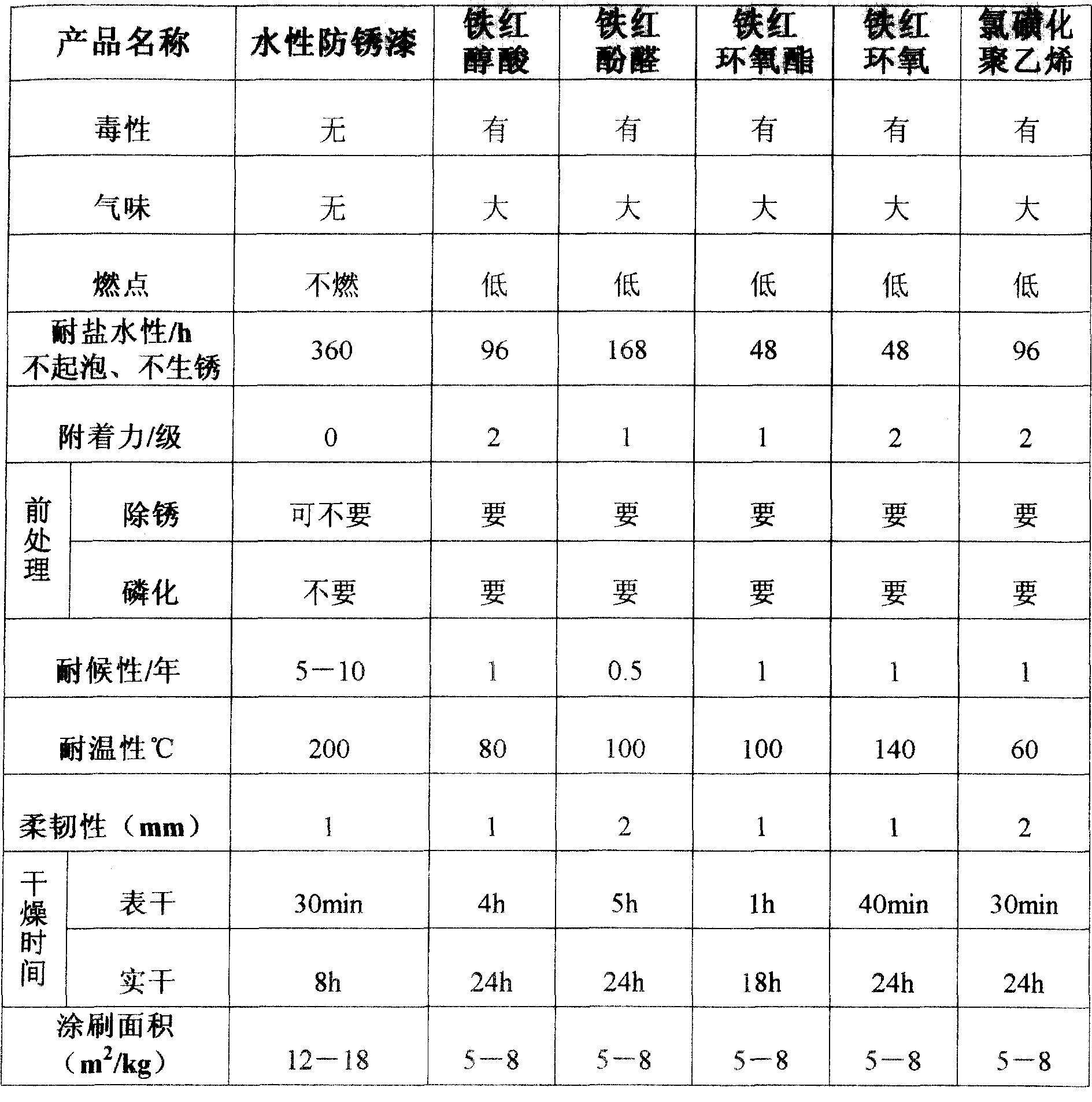

Aqueous antirust paint

InactiveCN1626591ALarge brushing areaFast dryingAnti-corrosive paintsEmulsion paintsEmulsionEnvironmental chemistry

An antirust water paint is proportionally prepared from deionized water, anticorrosino agent, antirust agent, defoaming agent, alkali-soluble thickening agent, filming aid, butanediol, disperser, alluminium phosphate, zinc oxide, titanium oxide powder, talc powder, zinc yellow, acrylate emulsion, ammonia water, hydroxyethyl cellulose, and gas-phase SiO2. Its advantages are no environmental pollution and incombustible.

Owner:上海石化博蓝涂装材料有限公司

Aqueous coating for decorating inner wall of antifouling building and preparation method of aqueous coating

InactiveCN104250493APrevent immersionStrong resistanceAntifouling/underwater paintsPaints with biocidesKaolin clayStain

The invention discloses an aqueous coating for decorating inner walls of antifouling buildings. The aqueous coating comprises the following components in parts by weight: 10-20 parts of deionized water, 0.5-0.8 part of a wetting dispersant, 0.1-0.3 part of a defoaming agent, 1-2 parts of propylene glycol, 15-20 parts of titanium dioxide, 5-8 parts of kaolin, 5-10 parts of talcum powder, 8-10 parts of wollastonite in powder, 2-5 parts of a nano stain-resistant additive, 30-40 parts of nano acrylic emulsion, 0.1-0.5 part of bactericide, 1-2 parts of a coalescing agent, 0.1-0.2 part of a PH adjusting agent and 0.3-0.5 part of a thickening agent. According to the aqueous coating, the nano acrylic emulsion is adopted as a base material, and the functional nano stain-resistant additive is added, so that a coated film has excellent resistance to multiple ordinary dirty marks, the sufficient emulsion use amount together with superfine pigment and packing ensures the tightness of the coated film, stains are effectively prevented from invading and are easy to clean, the coating is very good in adhesion to the base surface of an inner wall, resistant to water and alkali, high in covering property, large in coating area and good in construction performance.

Owner:安徽铁创新材料科技有限公司

Water soluble industry paint and its prepn process

InactiveCN1609151AGood for physical and mental healthImprove protectionEmulsion paintsHigh resistanceAcrylic resin

The present invention relates to paint technology and is one kind of water soluble industrial paint. The water soluble industrial paint consists of deionized water, dispersant, wetting agent, defoaming agent, corrosion retardant, triethanolamine, Fe2O3, zinc chrome yellow, mica powder, aluminum tripolyphosphate, talcum powder, barite, glycol, CS-12, alcoholic acid modified styrene-acrylic resin, preservative, bactericide, WT-105A and 113. Compared with available technology, the present invention has the advantages of water solvent, no toxicity, no smell, no burning and exploding, no pollution, high resistance to acid, alkali, salt, oil and other corrosive medium, etc.

Owner:广东泰锋环保涂料股份有限公司

Environment-friendly marine anticorrosive paint

InactiveCN106147307AImprove finenessStrong covering powerAntifouling/underwater paintsPaints with biocidesAdhesiveCitric Acid Monohydrate

The invention discloses environment-friendly marine anticorrosive paint. The paint is characterized by being prepared from components of raw materials in parts by weight as follows: 25-28 parts of polyamide resin, 8-12 parts of fluorinated acrylic ester, 3-5 parts of a biological antifouling agent, 2-3 parts of an organic tin complex, 2-4 parts of an adhesive, 2-4 parts of organobentonite, 5-6 parts of filler, 0.5-0.8 parts of polyethylene wax, 5-7 parts of propylene glycol, 0.3-0.5 parts of sodium hexametaphosphate and 0.5-0.7 parts of citric acid monohydrate. The environment-friendly marine anticorrosive paint has a good covering property and is light in texture, large in brushing area and high in adhesion power; due to addition of filler, the cost is greatly reduced, the environmental protection effect is remarkable, the paint has an anticorrosive function and has excellent affinity and a better adhesion effect through matched use with the adhesive; the biological antifouling agent has very low surface free energy, high hydrophobicity and high fouling release performance; due to addition of the organic tin complex, the dry adhesion force of the paint is improved, and a good flash-rust inhibition effect is realized.

Owner:QINGDAO ZHONGTIAN ZHICHENG SERVICE PLATFORM OF SCI & TECH CO LTD

Pollution-free environmental-friendly full-effective indoor coating and preparation method and application thereof

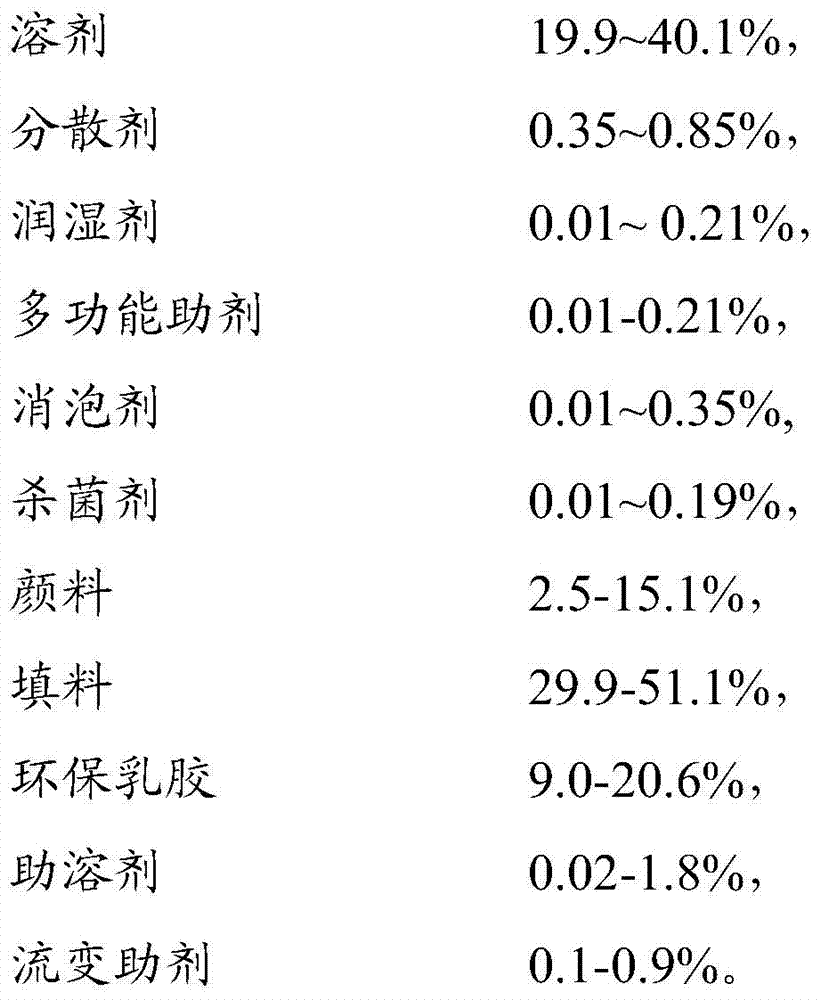

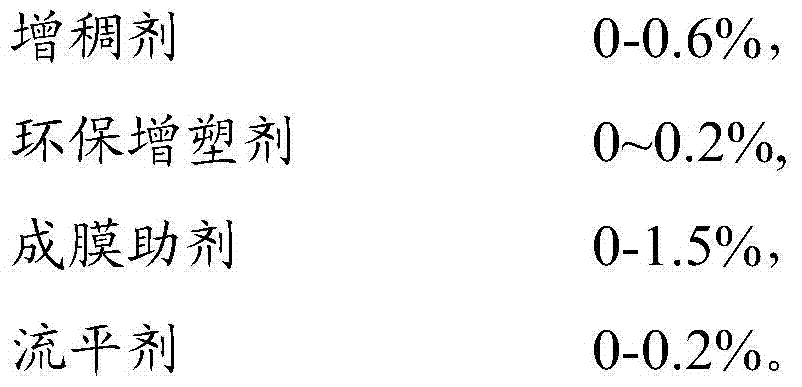

The invention provides a brand-new pollution-free environmental-friendly full-effective indoor coating and a preparation method and application thereof. The brand-new pollution-free environmental-friendly full-effective indoor coating is mainly refined through excellent formula and process which are summarized through multiple-time experiments by using an environmental-friendly emulsion, multiple environmental-friendly functional auxiliary agents, deionized water, a pigment, a filler, a film-forming auxiliary agent, an environmental-friendly plasticizing agent and the like, ensures that no side reaction is generated among materials, and enables the coating system to be very stable without generating obvious phenomena of after thickening and water diversion. The brand-new pollution-free environmental-friendly full-effective indoor coating provided by the invention is extremely high in performance-price ratio, free of halohydrocarbon substances, pollution-free, environmental-friendly, nontoxic and odorless, can be used for purifying the air by effectively removing indoor odor, has the characteristics of large coating area, good covering power, extremely good lacquer film tactile sensation, good leveling property, excellent scrubbing resistance and the like, meets the requirements for environmental friendliness and technology which are advocated by European Union, America and Japan at present, is on an advanced level of water paint in the same industry, and has good popularization prospects whether in the Europe and America and the Japan or in domestic markets.

Owner:哈尔滨绿科科技有限公司

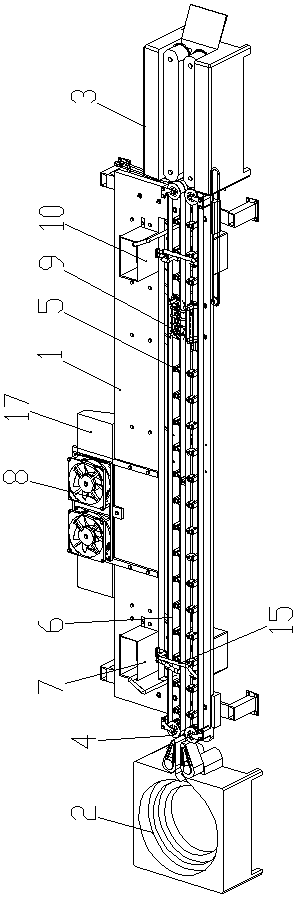

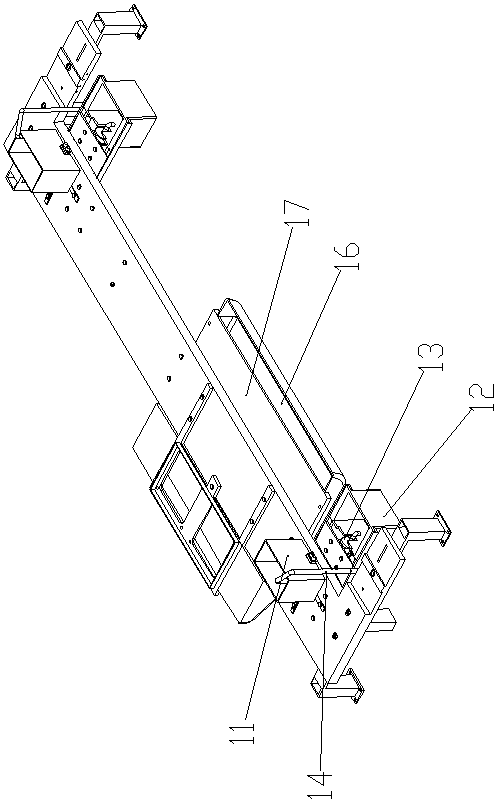

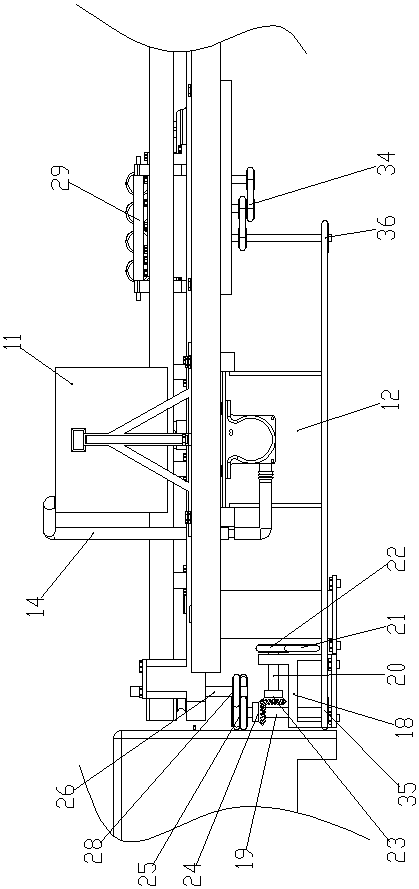

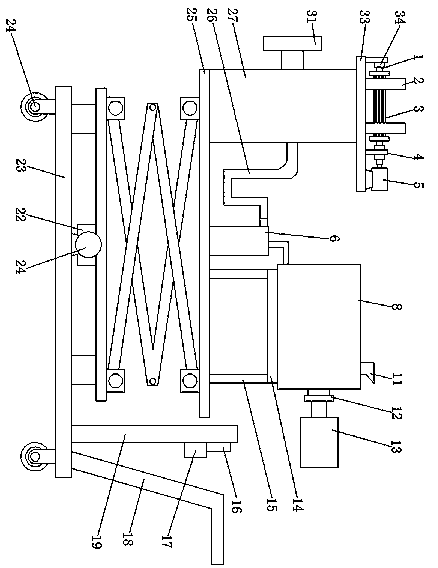

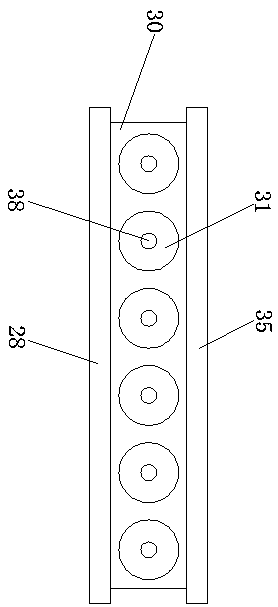

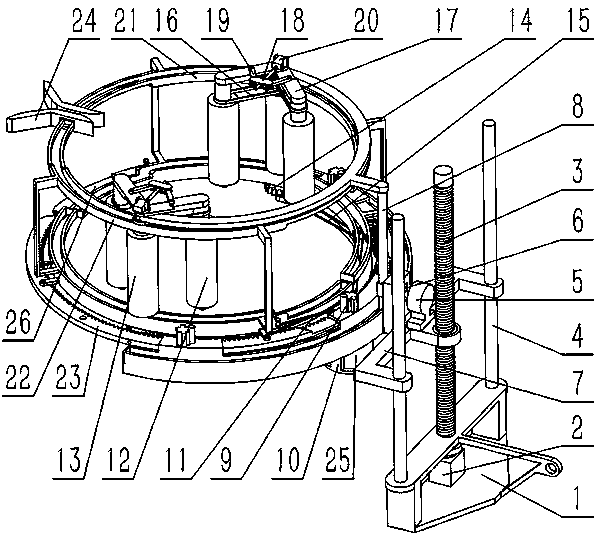

High-temperature inductance paint-removing tin-soldering integrated machine

ActiveCN107705978AIncrease productivityRapid responseInductances/transformers/magnets manufactureCopper wireElectric machinery

Disclosed is a high-temperature inductance paint-removing tin-soldering integrated machine. The integrated machine comprises a rack, the front portion of the rack is provided with a vibration plate, the rear portion of the rack is provided with a wave-peak tin-soldering machine, and the rack is provided with a driving motor and two conveying mechanisms arranged side by side in a left-right mode; each conveying mechanism comprises two rotating wheels and a plurality of supporting wheels, wherein the center lines of the rotating wheels and the center lines of the supporting wheels are all arranged vertically, one rotating wheel is rotatably connected to the front end of the rack, the other rotating wheel is rotatably connected to the rear end of the rack, a conveying belt is connected between the two rotating wheels, the length direction of the conveying belt is equal to that of the rack, and the supporting wheels are rotatably connected to the rack, all located between the left and right halves of the corresponding conveying belt and arranged side by side in the length direction of the corresponding conveying belt; thus, paint coats at the tail ends of copper wires of inductance coils are removed by means of assembly-line operation procedures, the tin-soldering operation is completed, and the production efficiency of the high-temperature inductance coils is improved.

Owner:HENAN POLYTECHNIC UNIV

Environment-friendly anti-corrosive paint

InactiveCN107446481AImprove dry adhesionImprove high temperature resistanceFireproof paintsAnti-corrosive paintsCarrageenanMicrosphere

The invention discloses an environment-friendly anti-corrosive paint. The paint is prepared from the following ingredients as raw materials in parts by weight: 80-90 parts of waterborne polyurethane emulsion, 60-78 parts of polyacrylate emulsion, 45-52 parts of polyacrylic ester emulsion, 25-32 parts of toluene diisocynate, 8-13 parts of a pigment, 1.0-3.2 parts of organic tin clathrate, 0.9-1.5 parts of a stabilizer, 1.2-2.3 parts of a thickening agent, 2.3-4.2 parts of a flatting agent and 5.0-10.9 parts of a filler; a binding agent is prepared from the following ingredients in parts by weight: 1.0-2.0 parts of sodium alginate, 2.0-3.0 parts of guar gum and 2.0-3.0 parts of carrageenan; the waterborne polyurethane emulsion, the polyacrylate emulsion and the polyacrylic ester emulsion serve as main raw materials, so that the paint has excellent covering power and strong adhesive power; by adding the organic tin clathrate, the dry adhesive force of a paint material is conducive to being improved, and when the environment-friendly anti-corrosive paint applied onto a surface layer of equipment is exposed to wind and rain, paint falling cannot happen so that the environment-friendly anti-corrosive paint has stable quality; the hollow microspheres improve the surface smoothness and rigidity of the environment-friendly anti-corrosive paint, and the scratch resistance of the environment-friendly anti-corrosive paint is improved.

Owner:贵州一涂建材科技有限公司

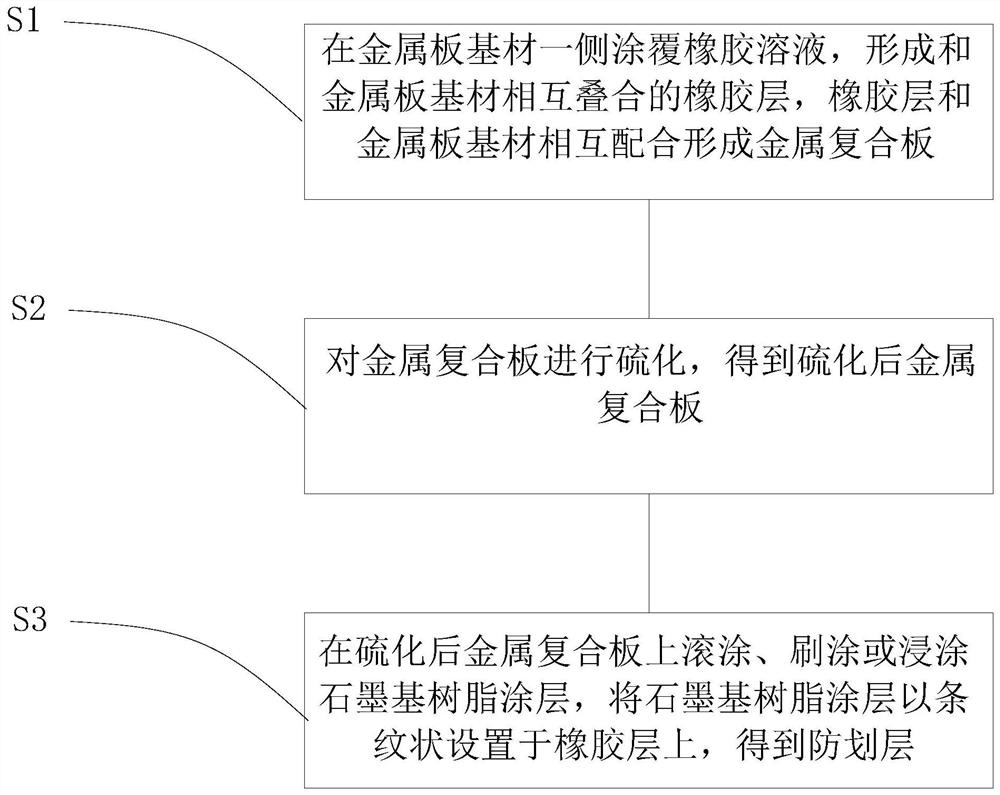

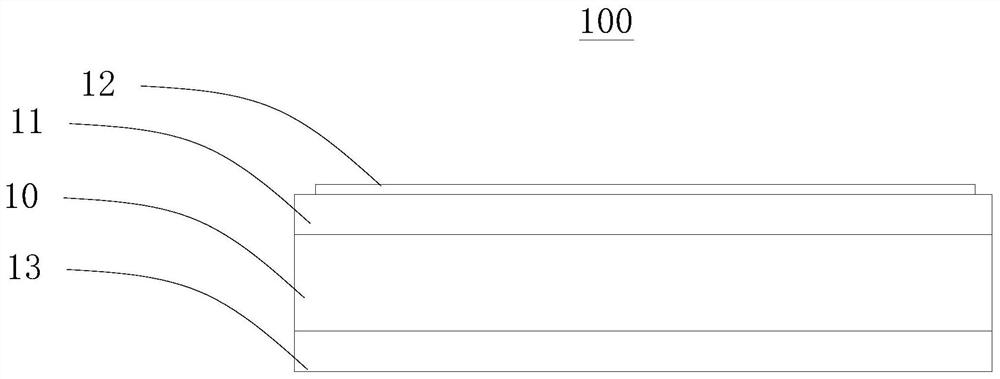

Automobile stripe silencing sheet and preparation process

ActiveCN112622858AOne-time brushing area is largeLarge brushing areaNoise/vibration controlFilm/foil adhesivesVulcanizationResin coating

The invention provides an automobile stripe silencing sheet and a preparation process, and relates to the technical field of silencing sheet production. The preparation process comprises the following steps: S1, coating one side of a metal plate base material with a rubber solution, and forming a rubber layer overlapped with the metal plate base material, wherein the rubber layer and the metal plate base material are matched with each other to form a metal composite plate; s2, vulcanizing the metal composite plate to obtain a vulcanized metal composite plate; and S3, roll coating, brush coating or dip-coating a graphite-based resin coating on the vulcanized metal composite plate, and arranging the graphite-based resin coating on the rubber layer in a striped manner to obtain the anti-scratching layer. According to the preparation process, the striped graphite-based resin coating can be processed on the rubber layer,so that the prepared silencing sheet has an anti-scratching effect, the metal composite plates are prevented from being stacked together in the product stamping process, burrs on the edges of a friction product are prevented from scratching the surface of the product in the packaging process, and the final forming quality of the product is improved. The silencing sheet is prepared by the process and has all the beneficial effects.

Owner:庄浩楠

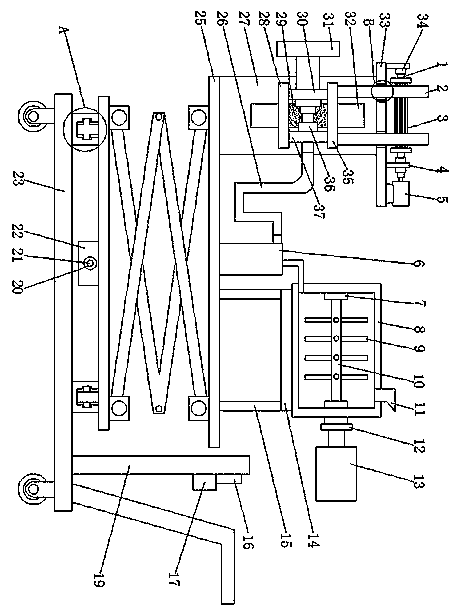

Spraying system for building construction and construction method thereof

InactiveCN110748125ALarge brushing areaEasy to paintBuilding constructionsArchitectural engineeringPipe

The invention belongs to the technical field of building construction and particularly provides a spraying system for building construction and a construction method thereof. The spraying system comprises a moving trolley. A lifting platform and a control table are arranged on the top of the moving trolley. A stirring barrel is installed on the top of the lifting platform. A plate brush capable ofmoving in a lifting manner is arranged on the top of the lifting platform through other parts. A first material pump is installed between the plate brush and the stirring barrel. A feeding opening ofthe first material pump communicates with the stirring barrel. A discharging opening of the first material pump fixedly communicates with an anti-explosion pipe. The tail end of the anti-explosive pipe fixedly communicates with a distributing bin. The plate brush communicates with the distributing bin. A second material pump is arranged in the plate brush. According to the spraying system, by arranging the lifting type spraying device, manual high-place operation is replaced, safety accidents caused by climbing and ascending of workers can be reduced, spraying efficiency of building construction is further improved greatly, and job processing is accelerated beneficially.

Owner:河南四建工程有限公司

Water-soluble camouflage coating and preparation method thereof

InactiveCN107163714ATo camouflageNo smellTemporary coatingsCamouflage paintsSpectral propertiesDefoamer

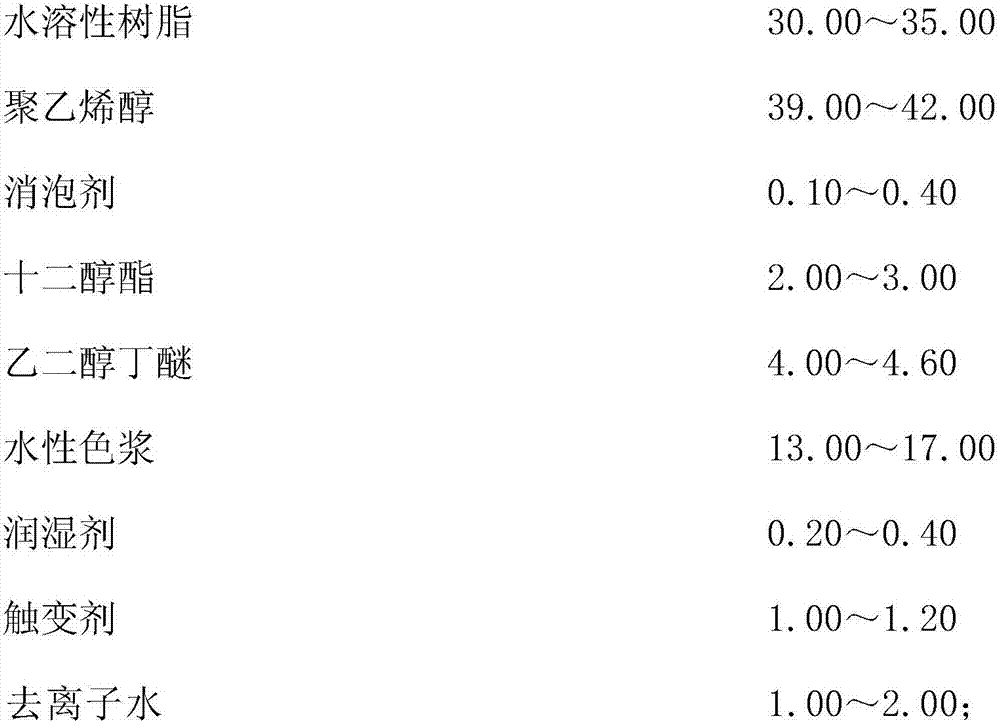

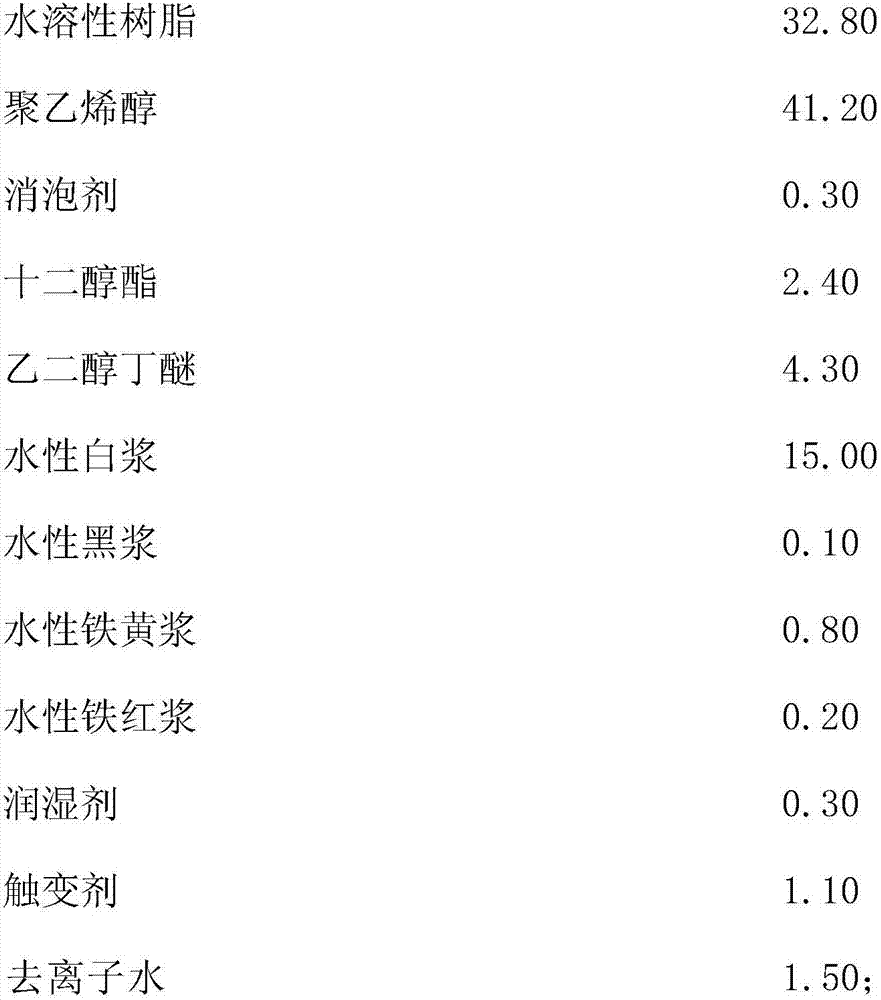

The invention relates to the field of coating, in particular to water-soluble camouflage coating and a preparation method thereof. The water-soluble camouflage coating comprises the following raw materials in parts by weight: 30.00-35.00 parts of water-soluble resin, 39.00-42.00 parts of polyvinyl alcohol, 0.10-0.40 parts of a defoamer, 2.00-3.00 parts of dodecanolate, 4.00-4.60 parts of ethylene glycol butyl ether, 13.00-17.00 parts of a waterborne color paste, 0.20-0.40 part of a wetting agent, 1.00-1.20 parts of a thixotropic agent and 1.00-2.00 parts of deionized water. The water-soluble resin is a main film-forming substance of the water-soluble camouflage coating; through optimization of a pigment, blending modification, careful selection of auxiliary agents and reasonable combination, physical and chemical properties and spectral properties of the water-soluble camouflage coating are met; in addition, the water-soluble camouflage coating not only is water-soluble, but also has certain water resistance, and can resist ordinary water pressure, rain erosion and the like.

Owner:CHANGZHOU JIAERKE SIMULATION EQUIP CO LTD

Two-component water-based woodware paint

InactiveCN104974613AGood effectResults firstAntifouling/underwater paintsPaints with biocidesPolymer scienceAcrylic resin

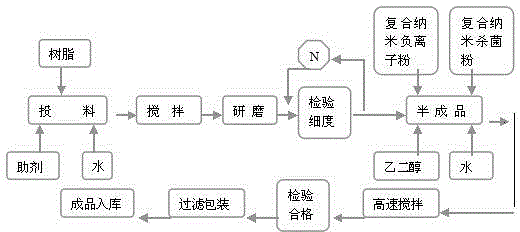

A two-component water-based woodware paint is characterized by being composed of water-based acrylic resin, a composite nano antiseptic powder, a composite nano negative ion powder, polyacrylic acid sodium salt, a mixture of aliphatic hydrocarbon and an emulsifier, a polyurethane polymer, ethylene glycol, water and water-based isocyanate with the weight ratio of (50-80):(2.5-10):(2.5-5):(1-5):(0.3-2):(3-6):(5-10):(10-25):(20-50). The product does not contain lead, mercury, chromium, benzene and other harmful substances, has the advantages of water resistance, moisture resistance, mould resistance, rust resistance, adhesion force, strong stability, large coating-brushing area, high-temperature resistance, aging resistance, hardness reaching F, scrub resistance, convenience and safety for use, and no pollution, and is applicable to any wood surface.

Owner:江苏瑞和新材料股份有限公司

Interior wall latex paint

InactiveCN109627861ASlow dryingHigh fullnessAntifouling/underwater paintsPaints with biocidesEmulsionAlcohol

The invention relates to interior wall latex paint. The interior wall latex paint is prepared from, by weight, 10-17.5 parts of deionized water, 0.5-0.7 part of a dispersing agent, 0.15-0.2 part of awetting agent, 0.3-0.4 part of an antifoaming agent, 1.5-2.0 parts of propylene glycol, 0.5-1 part of alcohol ester-12, 18-20 parts of titanium dioxide, 10-12.8 parts of heavy calcium carbonate powder, 38-40 parts of a functional emulsion and 1-1.2 parts of a thickening agent. The pH value of the interior wall latex paint is 8-9. The interior wall latex paint has the advantages that the interior wall latex paint has a hydrophobic effect similar to lotus leaves, the recoatability is good, the plumpness of paint film is high, and the water resistance and stain resistance are excellent.

Owner:重庆多仑建材有限公司

Nano-crystal-whisker thixotropy thickening agent for solvent-based coating and preparation method thereof

The invention discloses a nano-crystal-whisker thixotropy thickening agent for a solvent-based coating and a preparation method thereof. The thickening agent is prepared from, by weight, 15-25 parts of halloysite slag, 14-22 parts of hectorite, 9-18 parts of cell quartz, 22-28 parts of dolomite, 10-15 parts of sepiolite, 17-23 parts of pseudo-boehmite, 12-18 parts of asbestos tailings, 6-12 parts of chalk powder, 10-15 parts of calcium silicon slag, 5-10 parts of magnesium trisilicate, 13-21 parts of ceramic waste, 4-7 parts of potassium acetate, 3-6 parts of anhydrous sodium sulphate, 5-10 parts of a modifying agent A and 10-15 parts of a modifying agent B. The prepared nano-crystal-whisker thixotropy thickening agent has the advantages of being high in thickening performance, good in thixotropy, good in stability and the like; a coating system can be endowed with excellent thixotropic performance, a leveling property and sagging resistance in the coating construction process are improved, spraying or batch scraping or rolling brushing can be carried out easily, the painting area is increased, opening time for the coating is prolonged, and film formation can be achieved easily.

Owner:MINGGUANG FEIZHOU NEW MATERIAL

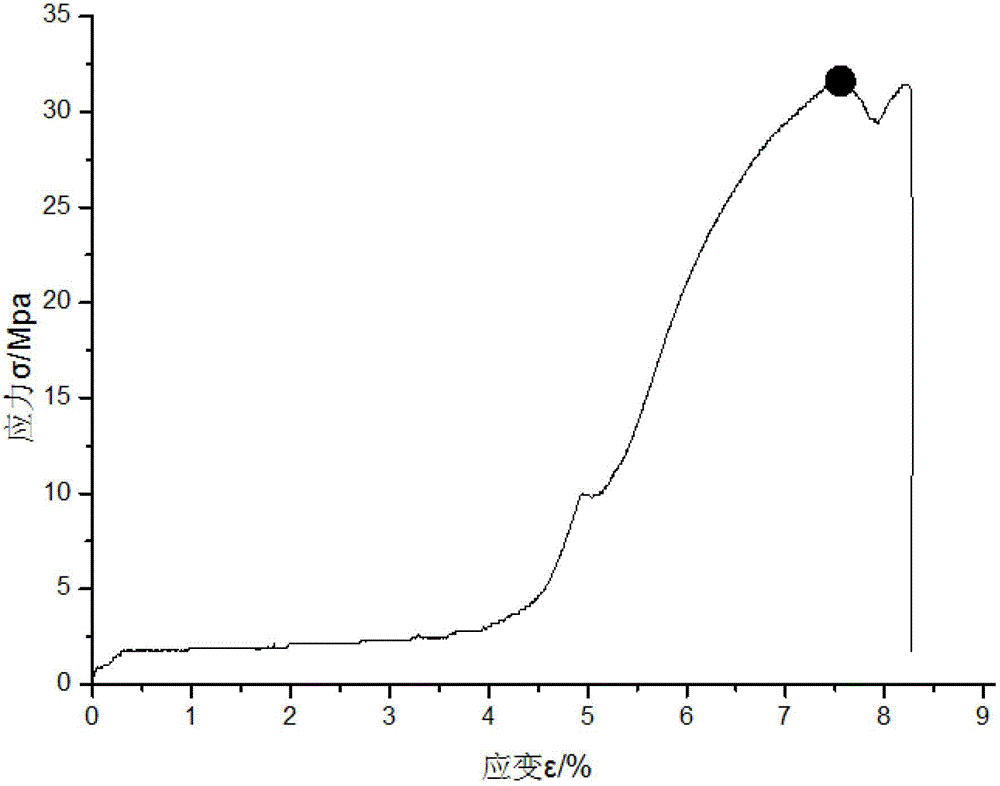

A kind of water-based polyurethane coating for concrete protection in cold area and preparation method thereof

ActiveCN108997919BReduce manufacturing costReduced stabilityAnti-corrosive paintsPolyurea/polyurethane coatingsFreeze thawingPolyurethane dispersion

The invention relates to a waterborne polyurethane coating for protection of concrete in cold areas and a preparation method thereof. The waterborne coating consists of a component A and a component B. The component A includes the components by weight: 40 to 70 parts of a waterborne polyurethane dispersion body, 0 to 20 parts of waterborne hydroxyl acrylic resin, 0 to 20 parts of waterborne polyurethane resin, 0 to 10 parts of a waterborne polytetrafluoroethylene emulsion, 0.1 to 8 parts of an auxiliary agent, 5 to 30 parts of pigments and fillers, and 7 to 10 parts of deionized water. The component B is a waterborne isocyanate curing agent with the addition amount of 10-15 parts. The waterborne polyurethane coating can be used normally at low temperature, can prevent concrete from occur water vapor erosion, freeze-thaw damage and other phenomena in cold climate, and slows down natural weathering speed.

Owner:铁科创恒新材料科技有限公司 +1

Water soluble industry paint and its preparation process

InactiveCN100469844CGood for physical and mental healthImprove protectionEmulsion paintsHigh resistanceAcrylic resin

The present invention relates to paint technology and is one kind of water soluble industrial paint. The water soluble industrial paint consists of deionized water, dispersant, wetting agent, defoaming agent, corrosion retardant, triethanolamine, Fe2O3, zinc chrome yellow, mica powder, aluminum tripolyphosphate, talcum powder, barite, glycol, CS-12, alcoholic acid modified styrene-acrylic resin, preservative, bactericide, WT-105A and 113. Compared with available technology, the present invention has the advantages of water solvent, no toxicity, no smell, no burning and exploding, no pollution, high resistance to acid, alkali, salt, oil and other corrosive medium, etc.

Owner:广东泰锋环保涂料股份有限公司

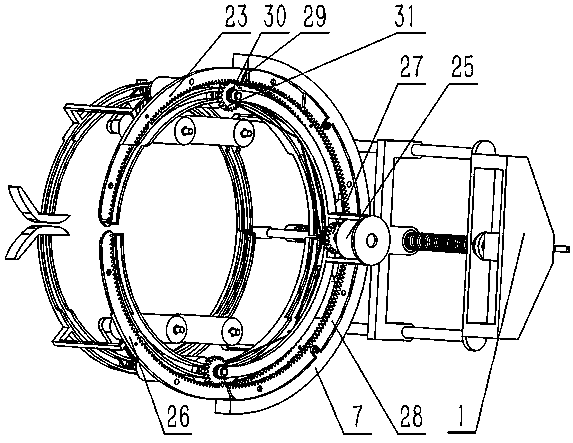

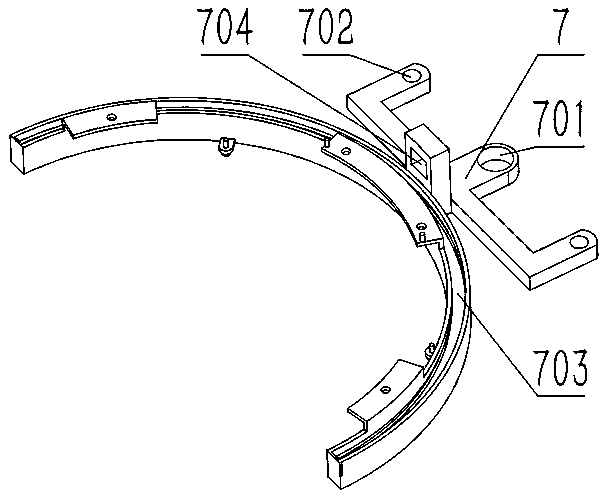

A garden green plant painting system

InactiveCN108126860BLarge brushing areaBrushing speed is fastLiquid surface applicatorsCoatingsElectric machineAgricultural engineering

The invention discloses a garden green plant brushing system. The garden green plant brushing system includes a support frame part, a drive motor working part and a brushing working part. The supportframe part includes a mounting frame, and a servo motor is disposed at the upper portion of the mounting frame. The drive motor working part includes a middle half-ring gear, the middle half-ring gearis mounted at the inner side of a bracket groove on a bracket, and a middle gear is installed on the middle half-ring gear in a meshed mode. The brushing working part includes a steady rest, and a left rotating frame and a right rotating frame are separately provided with a set of brushing unit. According to the garden green plant brushing system, paint rollers are used for brushing, so that thebrushing area of each time brushing and the brushing speed are increased; the structure is compact and is not affected by the green plant density; and the working principle of the garden green plant brushing system is reliable.

Owner:广州智境设计院有限公司

Aqueous antirust paint

InactiveCN100485007CGood for physical and mental healthImprove protectionAnti-corrosive paintsEmulsion paintsPhosphatePhosphoric acid

Owner:上海石化博蓝涂装材料有限公司

Health care lacquer

InactiveCN103242719AImprove immunityIncrease the oxygen content of the airAntifouling/underwater paintsPaints with biocidesDiseaseAntibiosis

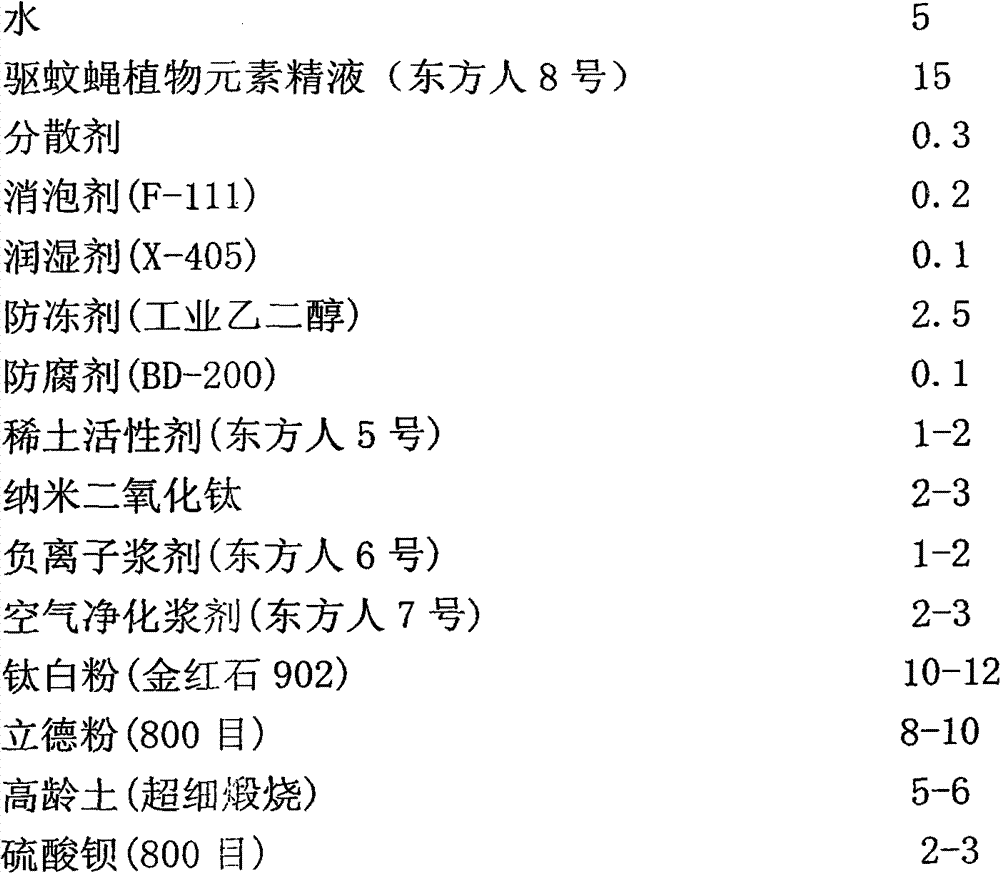

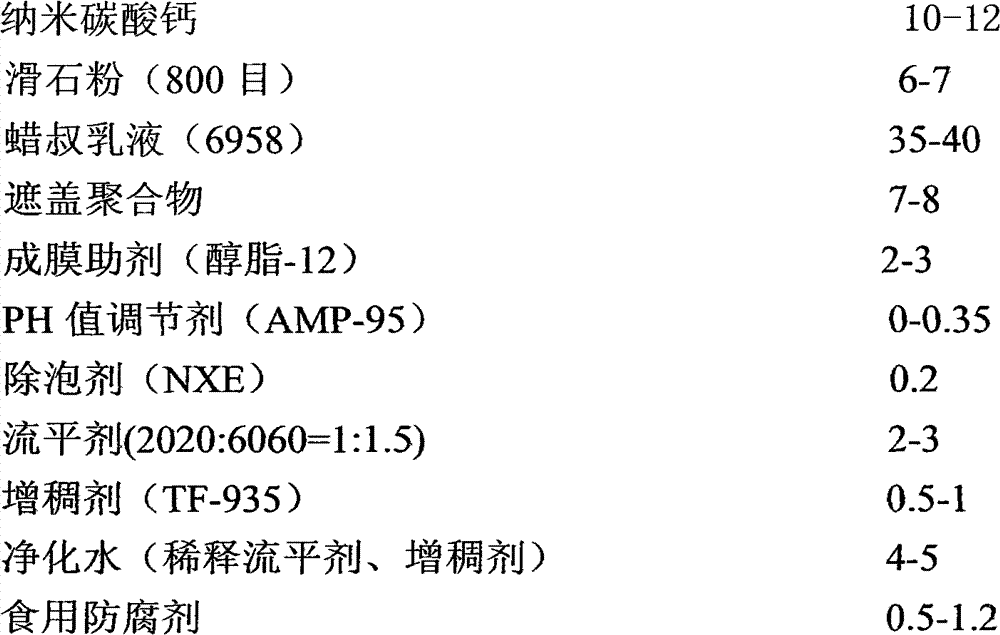

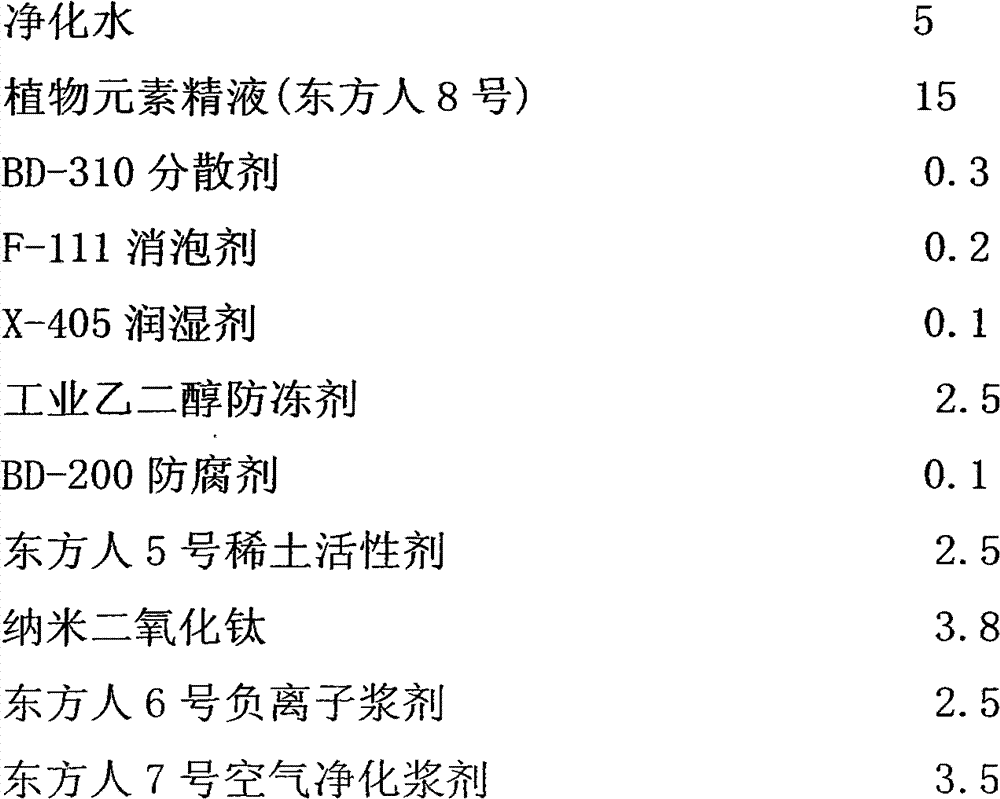

The invention relates to a formula of a health care lacquer and a preparation method thereof. The health care lacquer is composed of the following components in parts by weight (KG): 5 parts of water, 15 parts of mosquito and fly repelling plant element essential liquid (oriental No. 8), 0.3 part of a dispersing agent, 0.2 part of a defoamer (F-111), 0.1 part of a wetting agent (X-405), 2.5 parts of an antifreezing agent (industrial ethylene glycol), 0.1 part of a preservative (BD-200) and 1-2 parts of a rare-earth activator (oriental No. 5). The health care lacquer has the characteristics that mosquitoes and flies are repelled, negative oxygen ions are released, antibiosis is realized, harmful gases are adsorbed and air is purified; the health care lacquer overcomes the shortages of common properties of the health care lacquer produced in the past; and therefore, the invention provides a health care lacquer which is capable of enabling people to live in the environment without mosquitoes and flies spreading diseases, and integrated with the health care function.

Owner:WEIHAI ZIPU GRP CO LTD

Environment-friendly paint and preparation method thereof

InactiveCN106634490AImprove immunityIncrease the oxygen content of the airAntifouling/underwater paintsPaints with biocidesRare earthSlurry

The invention discloses environment-friendly paint and a preparation method thereof. The environment-friendly paint is prepared from the following formula components in parts by mass: 3 to 5 parts of a dispersant, 2 to 4 parts of polyoxyethylene lauryl ether, 3 to 5 parts of nano titanium dioxide, 1 to 3 parts of a de-foaming agent, 2 to 4 parts of a wetting agent, 3 to 5 parts of sodium chloride, 1 to 3 parts of air purifying slurry, 3 to 5 parts of an anti-freezing agent, 4 to 6 parts of radix stemonae, 2 to 4 parts of cyrtomium rhizome, 6 to 8 parts of titanium dioxide, 4 to 6 parts of ethylene glycol, 2 to 4 parts of a preservative and 5 to 7 parts of a rare-earth activating agent. The environment-friendly paint can be used for removing bacteria and odor and can also be used for improving the immunity of people; the oxygen content in the air of a living environment of people is increased and the effect of prolonging life is realized; the environment-friendly paint has the effect of enhancing scrubbing resistance; a special waterproof and ventilated formula is adopted, and a dense and special protecting film is formed on the surface layer of a wall surface, so that dirt is difficult to permeate and attach; the wall surface is not damaged after being scrubbed for a plurality of times and the color is still beautiful as new.

Owner:钦州市钦南区生产力促进中心

Paste solder for hard soldering of SiCp/Al composite material and preparation method and use method thereof

InactiveCN103100800BReduce in quantityImprove automationWelding/cutting media/materialsSoldering mediaAdhesiveTubing types

The invention relates to a paste solder for the hard soldering of a SiCp / Al composite material and a preparation method and use method thereof, and relates to a solder for the hard soldering of the SiCp / Al composite material and a preparation method and use method thereof. The paste solder for the hard soldering of the SiCp / Al composite material aims at the problem that the traditional strip-shaped solder or foil-shaped solder is adverse to the automation in a hard soldering process and is not suitable to weld an irregular, small-sized or geometrical complicated part. The paste solder for the hard soldering of the SiCp / Al composite material is prepared by mixing solder alloy powder, a soldering flux and an adhesive. The preparation method comprises the following steps of: 1, preparing the solder alloy powder; 2, preparing the soldering flux; 3, preparing the adhesive; and 4, mixing to prepare the hard soldering of the paste solder for the SiCp / Al composite material. The use method comprises the following steps of: adopting coating type cloth or needle tube type cloth; and then carrying out vacuum heating treatment so as to complete welding. The preparation method disclosed by the invention is mainly used for preparing the paste solder for the hard soldering of the SiCp / Al composite material.

Owner:HENAN POLYTECHNIC UNIV +2

Marine organism shell powder paint

ActiveCN102167936BImprove finenessHigh whitenessAlginic acid coatingsHyaluronic acid coatingsCitric Acid MonohydrateCitric acid

The invention provides a type of marine organism shell powder paint, mainly comprising biosynthesis adhesive, sodium hexametaphosphate, shell powder, emulsifier, and citric acid mono. The marine organism shell powder paint is purely natural, environment-friendly, of simple preparation and of low manufacturing cost, and has no toxic effects on human body.

Owner:青岛万源生物科技有限公司

Preparation technology of environment-friendly waterborne industrial paint with high salt fog resistance and high anti-corrosion and anti-rust performance

InactiveCN109233514AGood for physical and mental healthImprove protectionAnti-corrosive paintsEnvironmental resistanceAcrylic resin

The invention relates to the technical field of industrial paint production, and discloses a preparation technology of environment-friendly waterborne industrial paint with high salt fog resistance and high anti-corrosion and anti-rust performance. A preparation method of the environment-friendly waterborne industrial paint comprises the following steps: mixing deionized water, a dispersing agentand a defoaming agent together according to a certain mass ratio, putting into a dispersing tank, and stirring, wherein the stirring speed of a dispersing machine is 600-800 rpm and the stirring timeis 10-15 min; putting an anti-rust pigment, TXL, aluminum phosphate and mica powder into the dispersing tank, and uniformly stirring to obtain a target slurry, wherein the stirring speed of the dispersing machine is 650-850 rpm and the stirring time is 20-25 min; conveying the obtained slurry into a grinder through a diaphragm pump, grinding till the fineness is 15-30 micrometers, and after completion of grinding, continuing putting into the dispersing tank; and putting acrylic resin, a wetting agent and propylene glycol into the dispersing tank, and dispersing for 30 min by stirring at a rotation speed of 600 rpm. By the preparation technology of the environment-friendly waterborne industrial paint with high salt fog resistance and high anti-corrosion and anti-rust performance, the industrial paint not only has strong anti-corrosion performance, but also is environment-friendly and healthy.

Owner:浙江鑫翔环保科技有限公司

A kind of pollution-free and environment-friendly full-effect indoor coating and its preparation method and application

Owner:哈尔滨绿科科技有限公司

SBS universal glue and preparation thereof

Owner:SHANDONG EVERGAIN ADHESIVE CO LTD

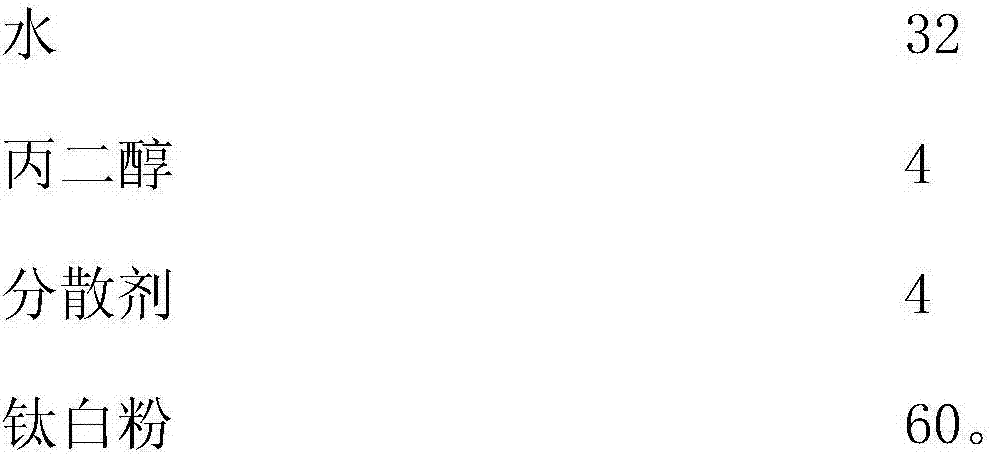

Compound preparation method of latex paint with low titanium white and high contrast ratio

A compound preparation method of a latex paint with low titanium white and high contrast ratio relates to a preparation method directly applicable to paints for building wall surfaces, and the method comprises the following steps: mixing titanium white powder with water and stirring the mixture; adding a dispersant and a wetting agent; putting the slurry into a mulser for emulsification, and detecting the particle size to be 0.2-0.5 microns; adding a pH adjusting agent to allow the pH to be 7-9; adding a polyurethane thickening agent and an alkali-swelling dispensing agent (to increase the viscosity and realize a stable storage) so as to prepare a titanium white slurry for later use; and adding emulsion paint special powder and an auxiliary agent into the prepared slurry to prepare the emulsion paint. According to the invention, the titanium white power is decreased by 40% under the condition that the same contrast ratio is reached, so the cost of the emulsion paint is reduced about 10-20%; in addition, the paint film is easier to adhere; the painting area is increased; the storage is more stable; and the times for rinsing resistance is also improved.

Owner:SHUCHENG RUIYU PAINT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com