A garden green plant painting system

A brushing and green planting technology, which is applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems of slow brushing speed and high manpower consumption, and achieves increased brushing area, reliable working principle and excellent structure compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

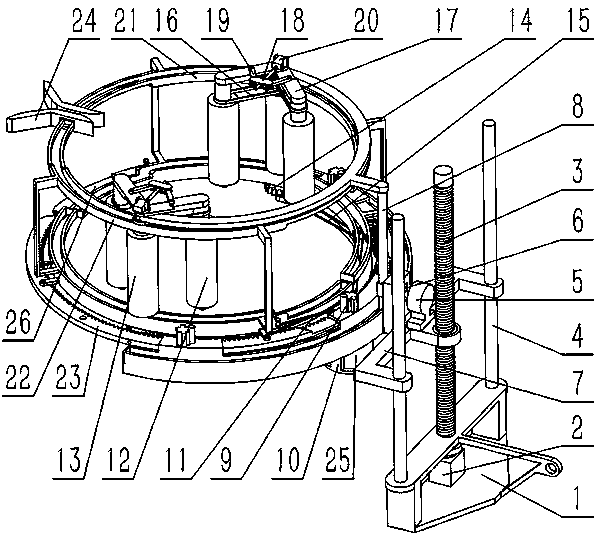

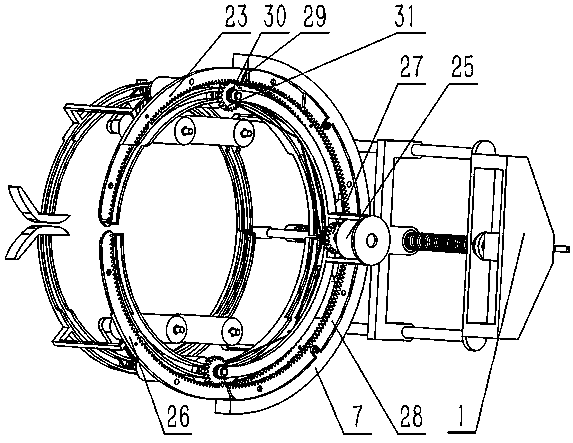

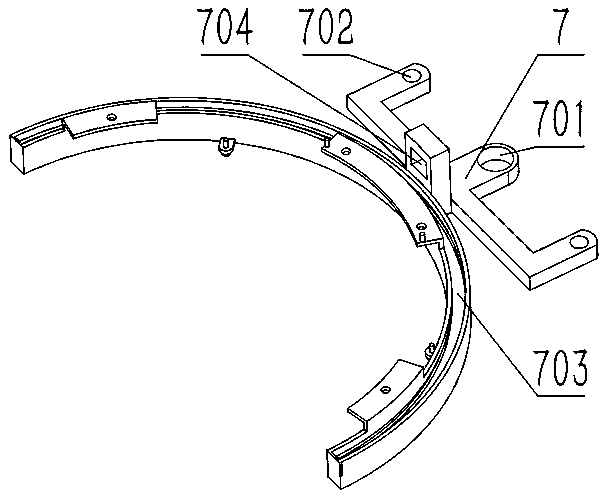

[0027] Example: such as Figure 1 to Figure 11 The garden green painting system shown includes a supporting frame part, a driving motor working part, and a painting working part. The support frame part includes a mounting frame 1, the upper part of the mounting frame 1 is provided with a servo motor 2, the main shaft of the servo motor 2 is vertically upward, the main shaft of the servo motor 2 is coaxially connected with a lead screw 3, and the left and right sides of the upper part of the mounting frame 1 are also vertical A stabilizer bar 4 is directly installed, and a bracket 7 is slidably installed on the two stabilizer bars 4 through the bracket light hole 702. The middle part of the bracket 7 is also provided with a bracket threaded hole 701, and is threadedly connected with the lead screw 3 through the bracket threaded hole 701; The support 7 is also provided with a support groove 703 and a support block 704, and the support 7 moves up and down along the stabilizer bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com