A kind of pollution-free and environment-friendly full-effect indoor coating and its preparation method and application

A coating and full-effect technology, applied in the direction of coating, etc., can solve the problems of failing to meet environmental protection requirements, water-based paints cannot continue to meet environmental protection indicators, and do not meet the corresponding national standards and export requirements, etc., and achieve excellent stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] The environmental protection latex used in embodiment 1 is Lvke B36 and preparation method thereof

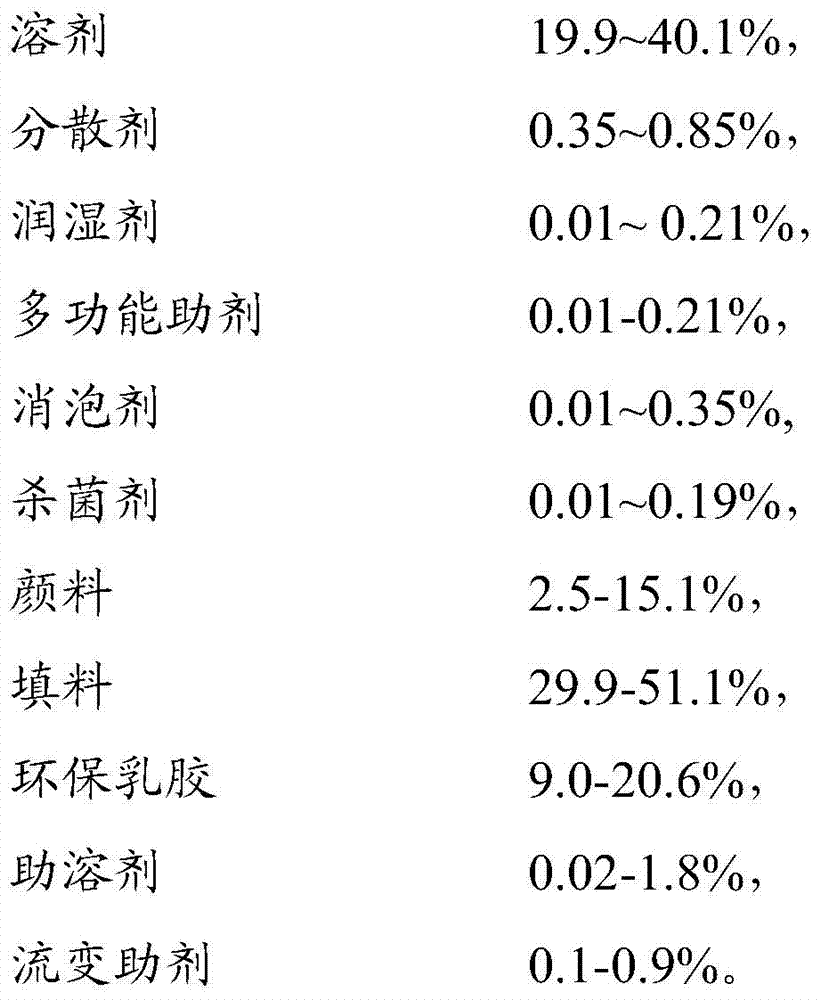

[0077] Lvke B36 is a high-performance environmentally friendly latex with a pH of 5.5-8.5, a solid content of 45.0%-60.0%, and a viscosity of 40-650mpa.s; it includes the following components in weight percentage:

[0078] It includes the following components by weight percentage:

[0079]

[0080] Wherein the concrete preparation method is as follows:

[0081]

[0082]

[0083] a. In the pre-dispersion tank (speed 30r / m), add 11.8% of the total deionized water, 0.1% buffer, 2.0% (negative 1.2%, non-0.8%) surfactant, stir for 25 minutes to dissolve, and then (Aromatic hydrocarbons, acrylic acid) Add all the monomers, adjust the rotation speed to 110r / m and stir at room temperature for 35min to obtain the premixed solution;

[0084] b. make initiator solution 1 with 0.15% ammonium persulfate mixed with 1.5% deionized water, and make initiator solution 2 with 0....

Embodiment 2

[0094] The preparation of embodiment 2 coating

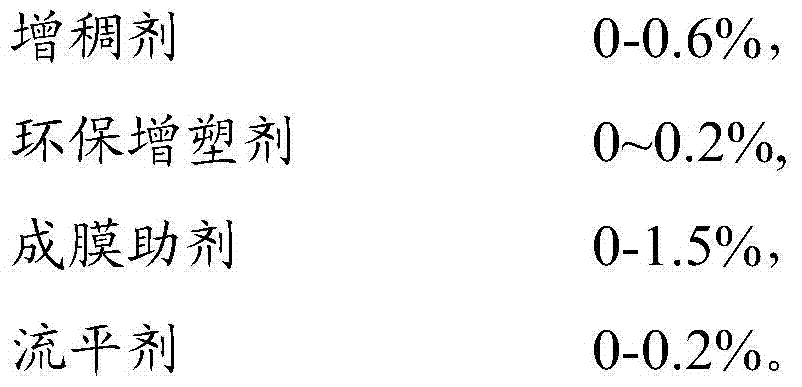

[0095] Make a kind of brand-new pollution-free environmental protection full-effect indoor coating with following each component weight ratio

[0096] Production method (all are mass percentages by weight):

[0097]

[0098]

[0099] a. Dissolution of thickener: put 20.7% water into equipment A, start stirring (motor speed is 700R / MIN), slowly pour all the thickener into equipment A with the above 20.7% water, stirring time is 25min ;

[0100] b. Adjust the rotation speed to 250R / MIN, measure 0.11% of NXE defoamer, all dispersants, wetting agents, bactericides, multi-functional additives, and environmental plasticizers into equipment B, stir evenly, and then put them into solution to thicken In the equipment A of the agent, then rinse the equipment B with 1% water, pour the remaining liquid into the equipment A and stir for 5 minutes;

[0101] c. Adjust the speed of the equipment to 600r / min after adding the pigment, ad...

Embodiment 3

[0112] The preparation of embodiment 3 coating

[0113] Make a kind of brand-new pollution-free environmental protection full-effect indoor coating with following each component weight ratio

[0114]

[0115]

[0116] Production method (all are mass percentages by weight):

[0117] a. Dissolution of thickener: put 20.2% water into equipment A, start stirring (motor speed is 500R / MIN), and slowly pour all the thickener into equipment A equipped with 20.2% water, and the stirring time is 40min;

[0118] b. Adjust the rotation speed to 250R / MIN, and measure 0.13% NXE defoamer. Add all the dispersants, multifunctional additives, and bactericides into equipment B and stir evenly, then put them into equipment A where the thickener is dissolved, then rinse equipment B with 1% water, pour the remaining liquid into equipment A and stir for 5 minutes;

[0119] c. Adjust the speed to 450r / min, add all the pigments in the order of BA-01 and then 5566, add the pigments, and adjust ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com