Interior wall latex paint

A technology of interior wall latex paint and functional emulsion, applied in the field of interior wall latex paint, can solve the problems of high production cost, poor hand feeling, and reduced environmental friendliness of hydrophobic interior wall latex paint, and achieve high fullness and good hand feeling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

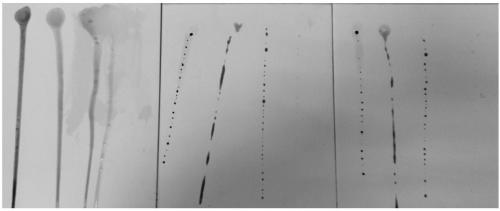

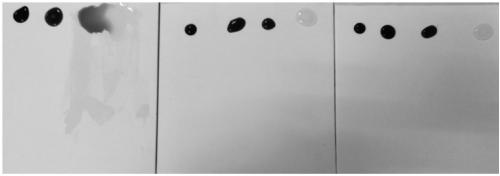

Image

Examples

Embodiment 1

[0059] 1) Take 80mL of deionized water and add it to the stirrer, add 6g of dispersant, 2g of wetting agent, 3g of defoamer, 15g of propylene glycol and 5g of alcohol ester-12 in sequence at a speed of 400-600r / min, and stir for 10- 20min;

[0060] 2) Continue to add 180g of titanium dioxide and 100g of heavy calcium powder, adjust the speed to 800-1200r / min, rinse the inner wall of the mixer with 20mL of deionized water, and stir for 20-40min until the fineness is ≤50μm;

[0061] 3) Reduce the speed to 400-600r / min, add 380g of functional emulsion, and stir for 10-20min;

[0062] 4) Add 10g of thickener at the speed of 400-800r / min until the viscosity is 100±2KU to obtain interior wall latex paint.

Embodiment 2

[0064] 1) Take 100mL of deionized water and add it to the stirrer, add 7g of dispersant, 2g of wetting agent, 4g of defoamer, 20g of propylene glycol and 7g of alcohol ester-12 in sequence at a speed of 400-600r / min, and stir for 10- 20min;

[0065] 2) Continue to add 190g of titanium dioxide and 110g of heavy calcium powder, adjust the speed to 800-1200r / min, rinse the inner wall of the mixer with 30mL of deionized water, and stir for 20-40min until the fineness is ≤50μm;

[0066] 3) Reduce the speed to 400-600r / min, add 390g of functional emulsion, and stir for 10-20min;

[0067]4) Add 10g of thickener at the speed of 400-800r / min until the viscosity is 100±2KU to obtain interior wall latex paint.

Embodiment 3

[0069] 1) Take 100mL of deionized water and add it to the stirrer, add 7g of dispersant, 2g of wetting agent, 4g of defoamer, 20g of propylene glycol and 10g of alcohol ester-12 in sequence at a speed of 400-600r / min, and stir for 10- 20min;

[0070] 2) Continue to add 200g of titanium dioxide and 120g of heavy calcium powder, adjust the speed to 800-1200r / min, wash the inner wall of the mixer with 20mL of deionized water, and stir for 20-40min until the fineness is ≤50μm;

[0071] 3) Reduce the speed to 400-600r / min, add 400g of functional emulsion, and stir for 10-20min;

[0072] 4) Add 10g of thickener at the speed of 400-800r / min until the viscosity is 100±2KU to obtain interior wall latex paint.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com