Constant-temperature dehumidification device and process

A technology of constant temperature dehumidification and equipment, which is applied in the production field of automobile interior covering parts, can solve the problems of low working efficiency of dehumidifiers, etc., and achieve the effect of fast drying of glue and increased output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

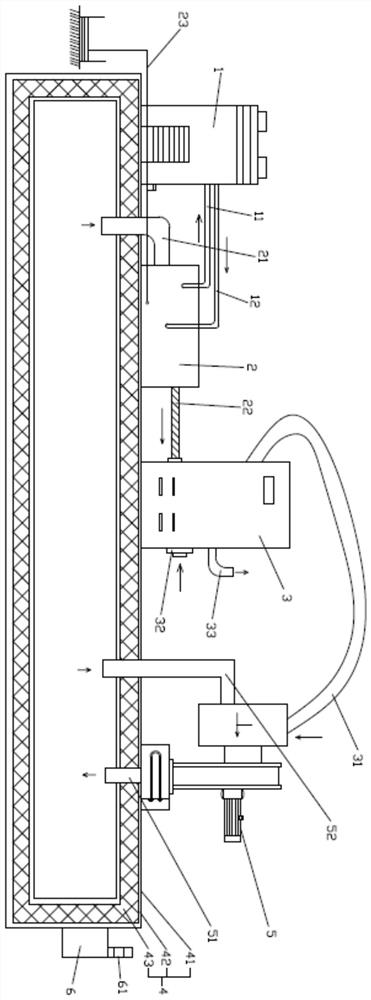

Image

Examples

Embodiment 2

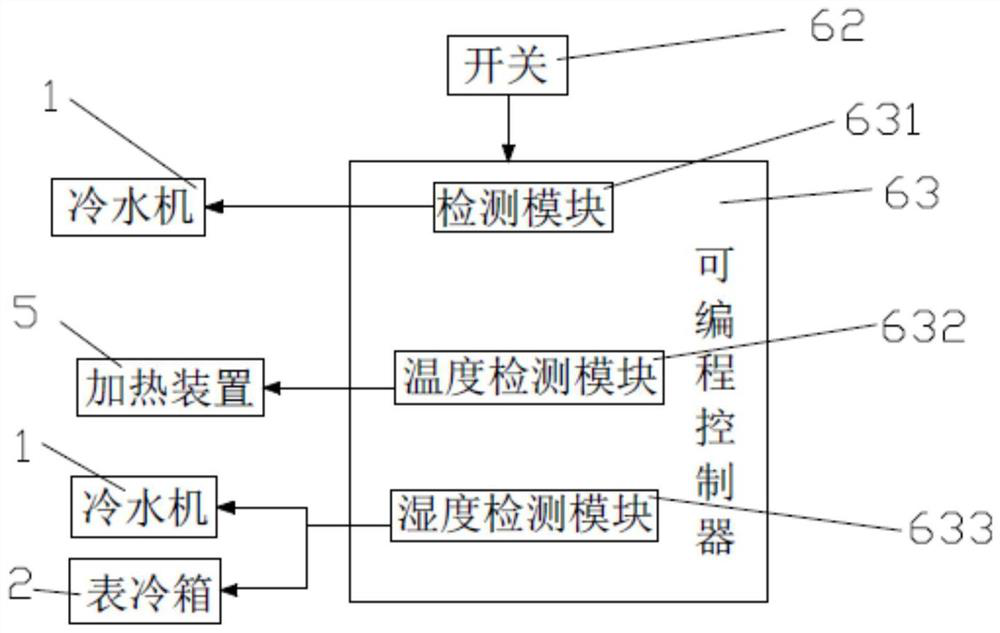

[0039] Embodiment 2: On the basis of Embodiment 1, the temperature is set at 60°C, the temperature difference compensation is 2°C, and when the temperature detection is 58°C, the heating device 5 starts heating until it reaches 60°C and stops working. Humidity regulation is controlled at 17%-20%. When the humidity drops to 17%, the dehumidifier 3 and the chiller 1 stop working, and when the humidity rises to 20%, the dehumidifier 3 and the chiller 1 restart.

Embodiment 3

[0040] Embodiment 3: On the basis of Embodiment 1, the temperature is set at 50°C, the temperature difference compensation is 3°C, the temperature detection is 47°C, the heating device 5 starts heating, and stops working when it is heated to 50°C. Humidity regulation is controlled at 10%-15%. When the humidity drops to 10%, the dehumidifier 3 and the chiller 1 stop working, and when the humidity rises to 15%, the dehumidifier 3 and the chiller 1 restart.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com