Paste solder for hard soldering of SiCp/Al composite material and preparation method and use method thereof

A technology of paste solder and alloy solder, which is applied in the direction of manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problem that strip-shaped or foil-shaped solder is unfavorable to the automation of the brazing process and is not suitable for irregular welding , small or geometrically complex parts, etc., to achieve the effect of facilitating automation, increasing the number of surface atoms, and increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

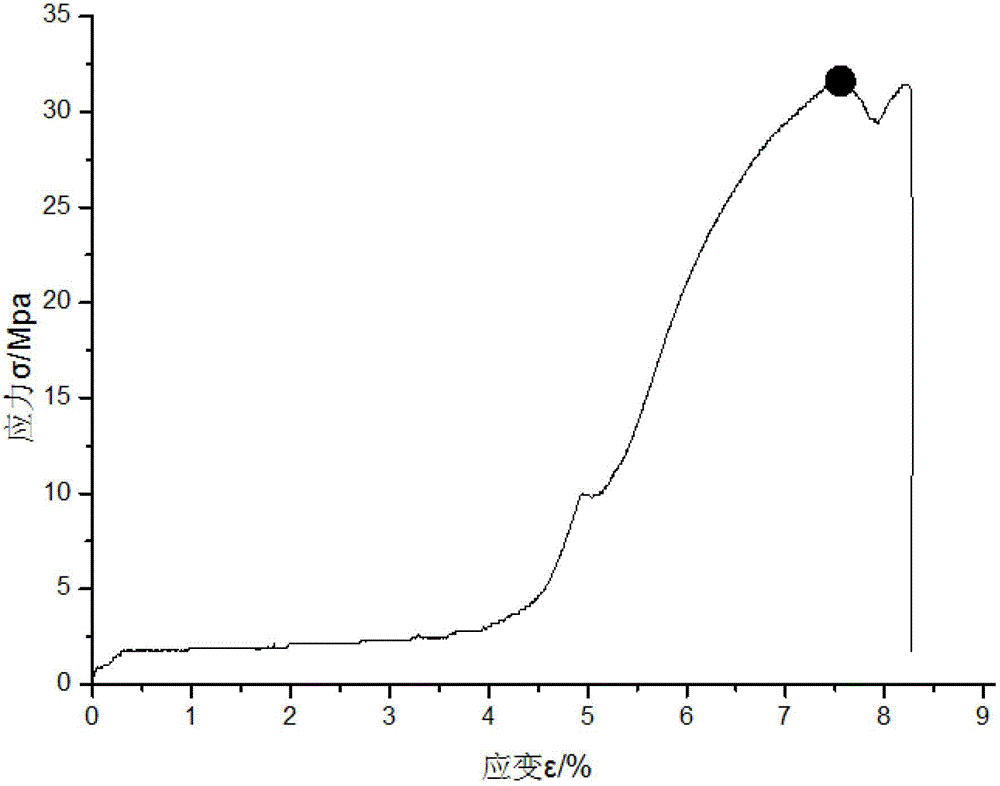

Image

Examples

specific Embodiment approach 1

[0019] Specific embodiment one: present embodiment is a kind of paste solder used for brazing of SiCp / Al composite material by mass percentage by 30%~35% alloy solder powder, 35%~40% flux and 25% to 35% binder is mixed.

[0020] The alloy solder powder described in this embodiment is composed of 21% to 25% of Cu, 4% to 6% of Si, 1% to 2% of Mg, 0.3% to 0.7% of Ni and 66% to 74% by mass percentage. % Al prepared.

[0021] The flux described in this embodiment is KF-AlF 3 Eutectic aluminum flux is added K 2 SiF 6 Mixed as a surfactant, wherein the KF-AlF 3 Eutectic aluminum flux with K 2 SiF 6 The mass ratio is 1:(0.074~0.131).

[0022] The binder described in this embodiment is prepared by mixing 85% to 90% of white oil, 6% to 10% of rosin resin, 2% to 5% of glycerin and 0.5% to 1.5% of hydrogenated castor oil according to the mass percentage. become.

[0023] The brazing alloy powder in this embodiment has a particle size of 5 μm to 25 μm.

[0024] The viscosity of t...

specific Embodiment approach 2

[0030] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the white oil has a flash point of 180° C. to 190° C. and a viscosity of 3.5 cp to 5 cp. Others are the same as the first embodiment.

specific Embodiment approach 3

[0031] Specific embodiment three: the present embodiment is a kind of preparation method for the paste solder of SiCp / Al composite material brazing, specifically is finished according to the following steps:

[0032] 1. Preparation of alloy solder powder: ① Preparation of materials: Firstly, cut or crush the raw materials containing Cu, Si, Mg, Ni and Al to a particle size of 5mm-20mm, and then put them into alcohol for ultrasonication Clean for 15min to 25min, and then prepare materials according to the mass percentage of 21% to 25% of Cu, 4% to 6% of Si, 1% to 2% of Mg, 0.3% to 0.7% of Ni and 66% to 74% of Al ; ② Nitrogen atomization: put the materials prepared in step ① into an intermediate frequency induction furnace for melting, and smelt them in a vacuum of 0.5×10 -3 Pa~1.5×10 -3 Pa and heating rate of 40°C / min~60°C / min are melted into molten metal, and then the molten metal is passed through the annular nozzle. mm, and the annular seam gap of the annular seam nozzle i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com