Automobile stripe silencing sheet and preparation process

A preparation process and technology of sound-absorbing sheets, applied in the direction of noise/vibration control, brakes, mechanical equipment, etc., can solve the problems of not having scratch resistance, affecting the quality and use effect of formed sound-absorbing sheets, achieving low loss and saving raw materials , Strengthen the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

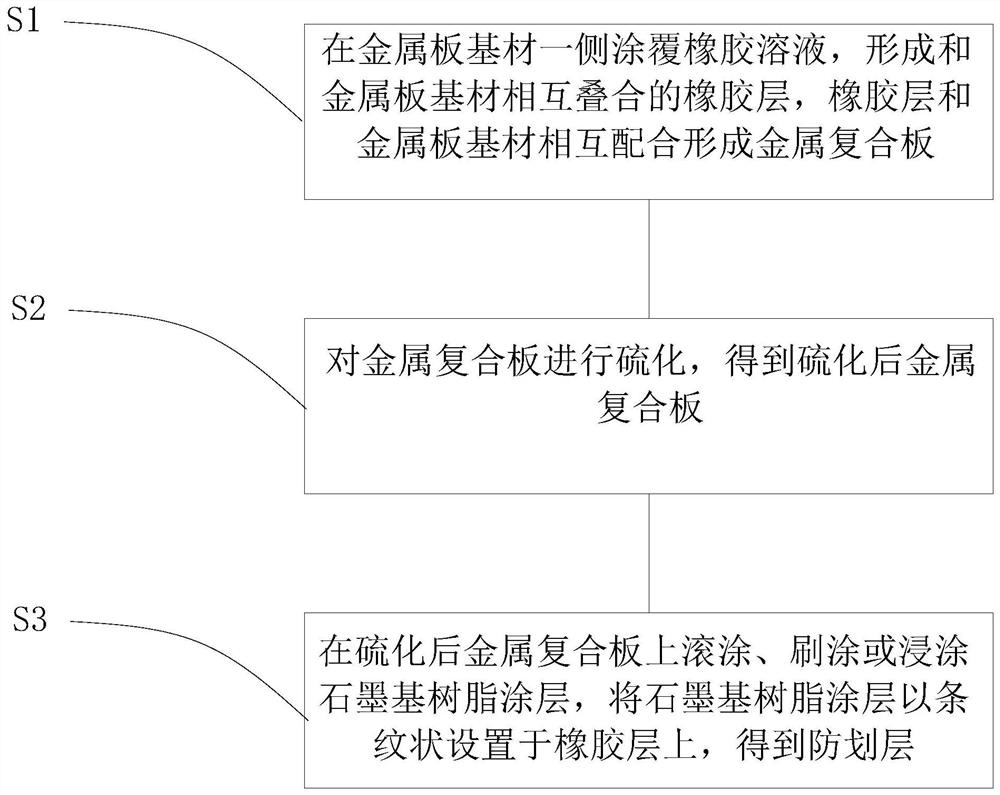

[0042] Please refer to figure 1 , the present embodiment provides a preparation process of automobile stripe sound-absorbing sheet 100, which includes the following steps:

[0043] S1, coating the rubber solution on one side of the metal plate base material 10 to form a rubber layer 11 superimposed on the metal plate base material 10, and the rubber layer 11 and the metal plate base material 10 cooperate with each other to form a metal composite plate;

[0044] S2, vulcanizing the metal composite board to obtain a vulcanized metal composite board;

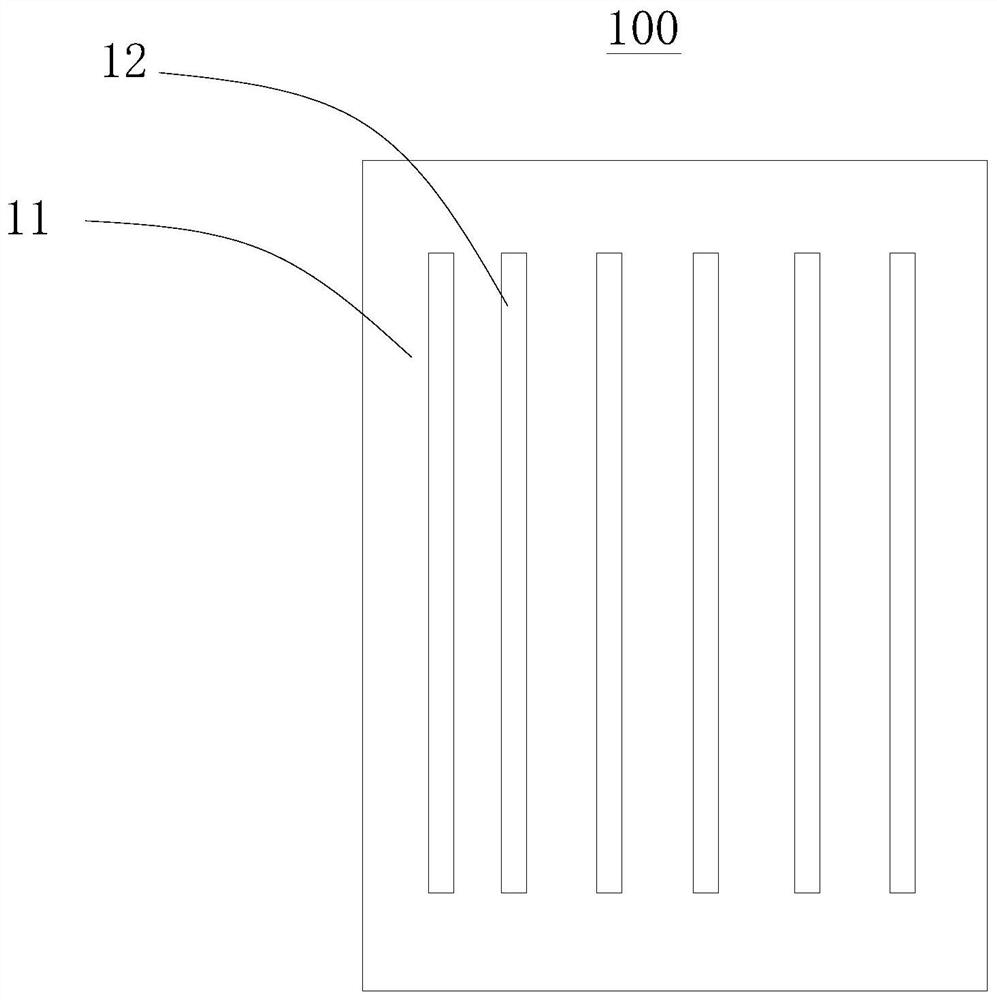

[0045] S3, rolling, brushing or dip-coating the graphite-based resin coating on the vulcanized metal composite plate, and disposing the graphite-based resin coating on the rubber layer 11 in stripes to obtain the anti-scratch layer 12 .

[0046] The preparation process of the automobile stripe sound-absorbing sheet 100 can process a stripe-shaped graphite-based resin coating on the rubber layer 11, so that the prepared automobile-...

Embodiment 2

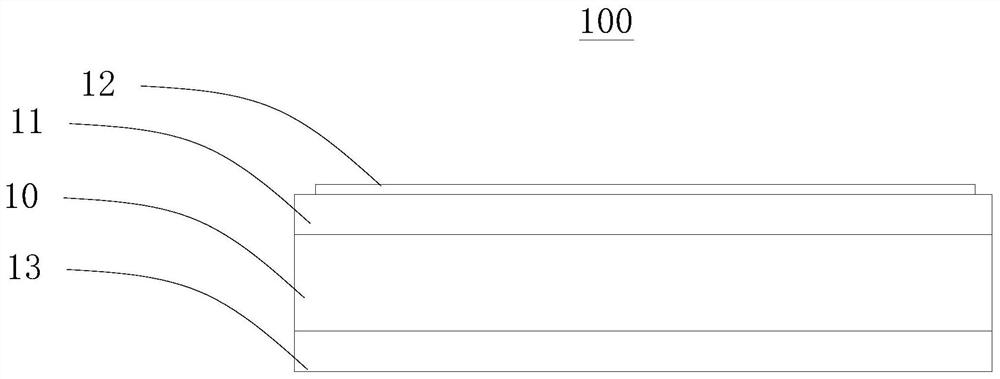

[0057] Please refer to figure 2 and image 3 , this embodiment provides an automobile stripe sound-absorbing sheet 100 prepared by the above-mentioned preparation process. The automobile stripe sound-absorbing sheet 100 comprises a metal plate base material 10, a rubber layer 11 and an adhesive layer 13, and the rubber layer 11, the metal plate base material 10 and the adhesive layer 13 are laminated in sequence, and the rubber layer 11 is provided with Stripe-shaped scratch-resistant layer 12 . It is worth noting that the sound is produced by vibration. The noise during braking is produced by the frictional vibration between the friction pad and the brake disc or brake drum. Only the sound of a certain frequency can attract people's attention. One of the components, it is mainly composed of brake lining (friction material part) and rigid back (metal part), the sound wave will change once from the friction lining to the rigid back, and from the rigid back to the metal plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com