Water-soluble camouflage coating and preparation method thereof

A water-soluble and paint technology, applied in the field of paint, can solve the problems of serious equipment application, many volatile substances, difficult to wash, etc., and achieve the effect of non-flammable and non-explosive safety, large brushing area and less volatile substances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

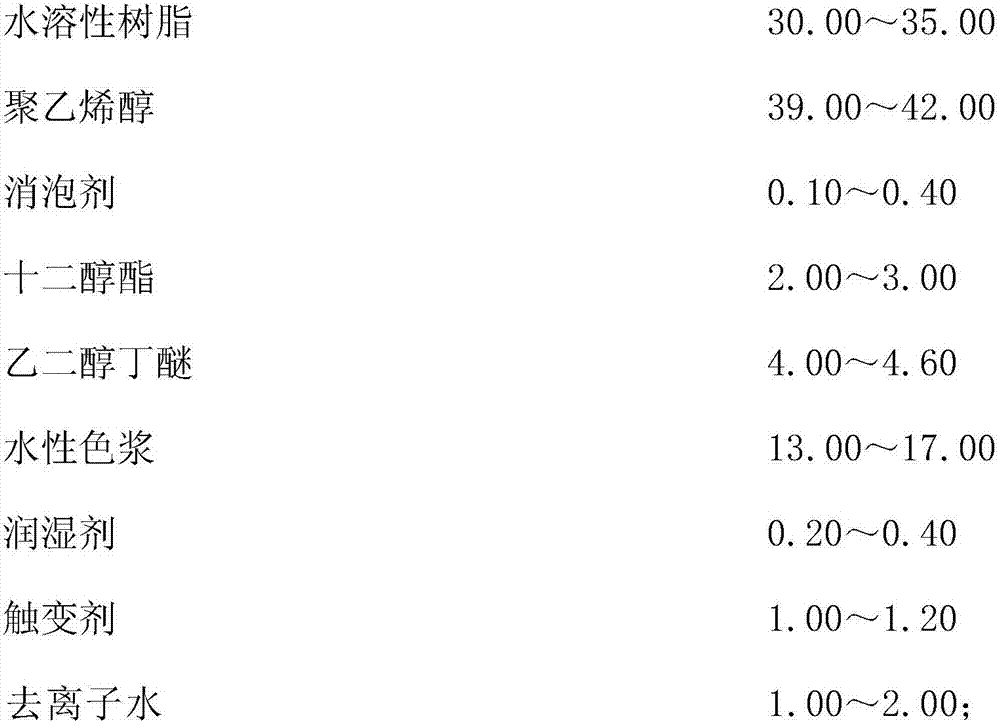

[0025] A water-soluble sand color camouflage camouflage paint, comprising the following raw materials in parts by mass:

[0026]

[0027] The weight fraction of polyvinyl alcohol is 10%.

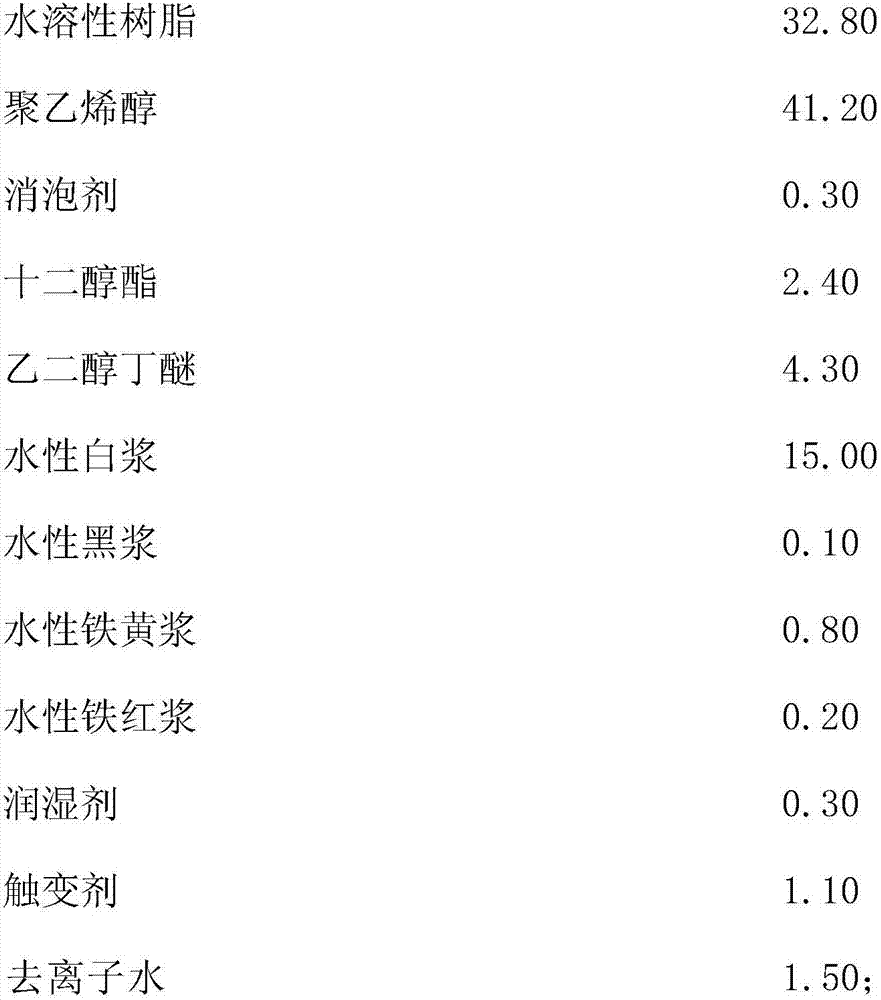

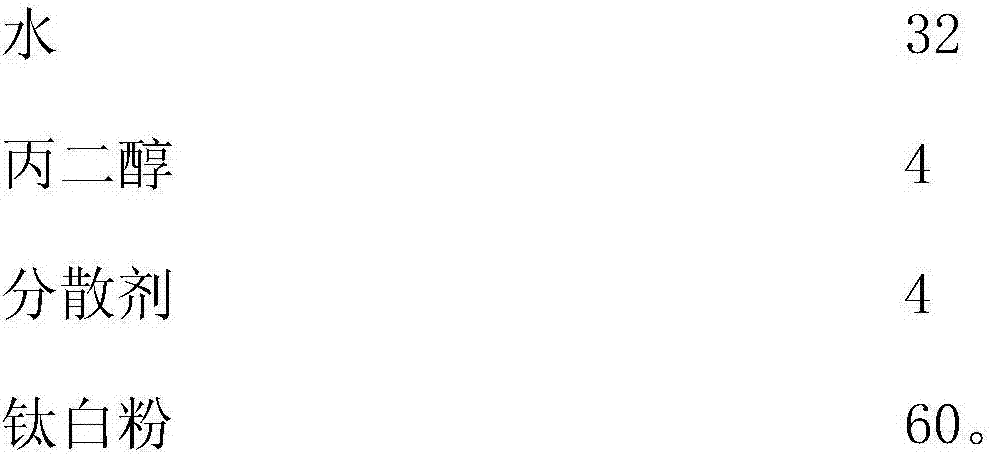

[0028] Wherein, the water-based white pulp comprises the following raw materials in parts by mass:

[0029]

[0030] The water-based black pulp comprises the following raw materials in parts by mass:

[0031]

[0032] The water-based iron yellow slurry comprises the following raw materials in parts by mass:

[0033]

[0034] The water-based iron red pulp comprises the following raw materials in parts by mass:

[0035]

[0036] A water-soluble sand color camouflage camouflage paint and a preparation method thereof, comprising the following steps:

[0037] (1) Ingredients, add 32.80 parts of water-soluble resin, 41.20 parts of polyvinyl alcohol, 2.40 parts of lauryl alcohol ester and 4.30 parts of ethylene glycol butyl ether in the batching tank, stir while adding, and mix th...

Embodiment 2

[0044] A kind of water-soluble green camouflage camouflage paint, comprises the raw material of following mass parts:

[0045]

[0046] The weight fraction of polyvinyl alcohol is 10%.

[0047] Wherein, the water-based chromium oxide green slurry includes the following raw materials in parts by mass:

[0048]

[0049] The water-based medium yellow pulp comprises the following raw materials in parts by mass:

[0050]

[0051] The water-based iron red pulp comprises the following raw materials in parts by mass:

[0052]

[0053] A kind of water-soluble green camouflage paint and preparation method thereof, comprises the following steps:

[0054] (1) Ingredients, add 32.80 parts of water-soluble resin, 41.20 parts of polyvinyl alcohol, 2.40 parts of lauryl alcohol ester and 4.30 parts of ethylene glycol butyl ether in the batching tank, stir while adding, and mix the above materials Fully stir evenly, set the stirring speed to 500 rpm, and stir for 10 minutes;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com