A kind of water-based polyurethane coating for concrete protection in cold area and preparation method thereof

A water-based polyurethane technology in cold regions, applied in polyurea/polyurethane coatings, anti-corrosion coatings, coatings, etc., can solve problems that do not meet environmental conditions and environmental protection requirements, and achieve slowing down of natural weathering speed, low production costs, and brushing large area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

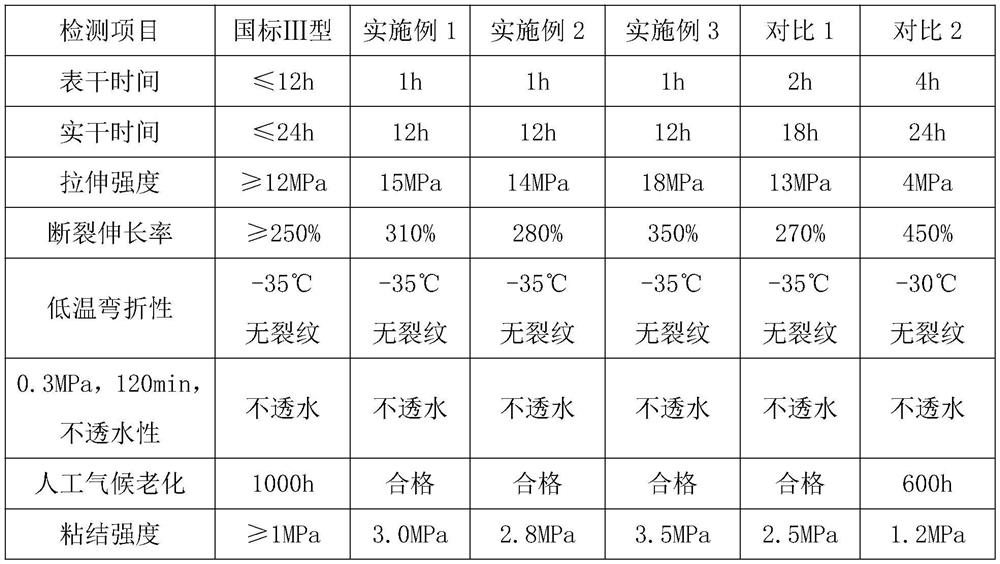

Examples

Embodiment 1

[0031] A kind of waterborne polyurethane coating that is used for concrete protection in cold area, its preparation method is as follows:

[0032] (1) Mix 8 parts of deionized water, 0.2 part of wetting agent, 0.6 part of dispersant, and 0.2 part of defoamer evenly to obtain a premix;

[0033] (2) Add 15 parts of titanium dioxide, 3.5 parts of mica powder, and 2.5 parts of talcum powder to the premix prepared in step (1), and after high-speed dispersion, grind with a horizontal sand mill to form a pigment slurry;

[0034] (3) Mix 50 parts of water-based polyurethane dispersion, 10 parts of water-based hydroxyacrylic resin, 5 parts of water-based high-solid amino acid ester resin, and 5 parts of water-based polytetrafluoroethylene emulsion, and stir to make a premixed base material;

[0035] (4) Put the premixed base material prepared in step (3) into the paint mixing kettle, add the pigment slurry prepared in step (2), add 0.2 parts of bactericide, 2 parts of cosolvent, 0.2 pa...

Embodiment 2

[0039] A kind of waterborne polyurethane coating that is used for concrete protection in cold area, its preparation method is as follows:

[0040] (1) Mix 10 parts of deionized water, 0.2 part of wetting agent, 0.8 part of dispersant, and 0.2 part of defoamer evenly to obtain a premixed liquid;

[0041] (2) Add 17.5 parts of titanium dioxide, 4 parts of sericite powder, and 2.5 parts of talcum powder to the premix prepared in step (1), and after high-speed dispersion, grind with a horizontal sand mill to form a pigment slurry;

[0042] (3) Mix 45 parts of water-based polyurethane dispersions, 8 parts of water-based hydroxyacrylic resins, 10 parts of water-based high-solid amino acid ester resins, and 5 parts of water-based polytetrafluoroethylene emulsions, and stir them evenly to make a premixed base material;

[0043] (4) Put the premixed base material prepared in step (3) into the paint mixing kettle, add the pigment paste prepared in step (2), add 0.2 parts of bactericide,...

Embodiment 3

[0047] A kind of waterborne polyurethane coating that is used for concrete protection in cold area, its preparation method is as follows:

[0048] (1) Mix 9 parts of deionized water, 0.2 part of wetting agent, 0.7 part of dispersant, and 0.2 part of defoamer evenly to obtain a premix;

[0049](2) Add 10 parts of titanium dioxide, 3.5 parts of sericite powder, and 5 parts of talcum powder to the premix prepared in step (1), and after high-speed dispersion, grind with a horizontal sand mill to form a pigment slurry;

[0050] (3) Mix 55 parts of water-based polyurethane dispersions, 5 parts of water-based hydroxyacrylic resins, 8 parts of water-based high-solid amino acid ester resins, and 5 parts of water-based polytetrafluoroethylene emulsions, and make a premixed base material after stirring;

[0051] (4) Put the premixed base material prepared in step (3) into the paint mixing kettle, add the pigment slurry prepared in step (2), add 0.2 parts of bactericide, 2 parts of cosolv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com