Spraying system for building construction and construction method thereof

A technology of building construction and construction method, applied in the direction of building, building structure, etc., can solve problems such as low efficiency and danger, and achieve the effect of guaranteed painting effect, high construction efficiency, and wide painting area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

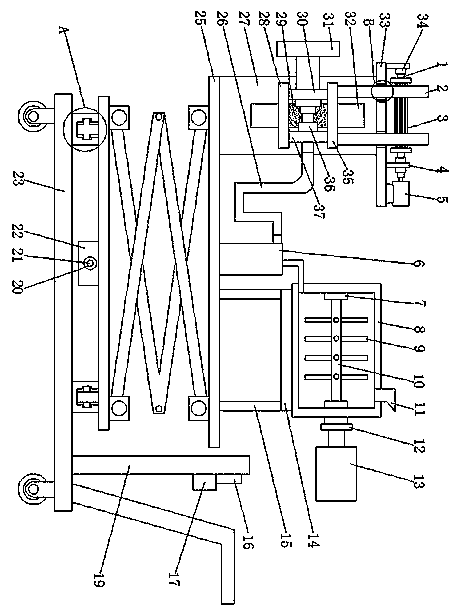

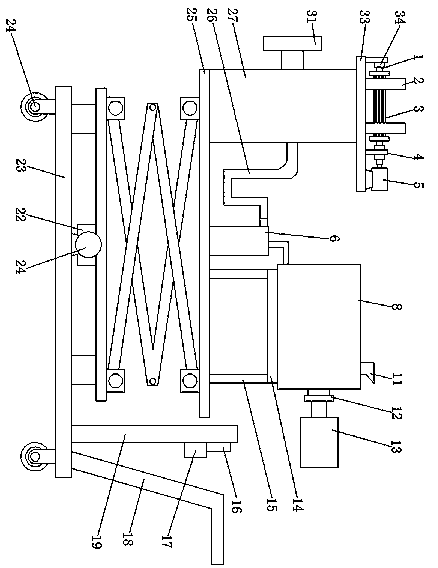

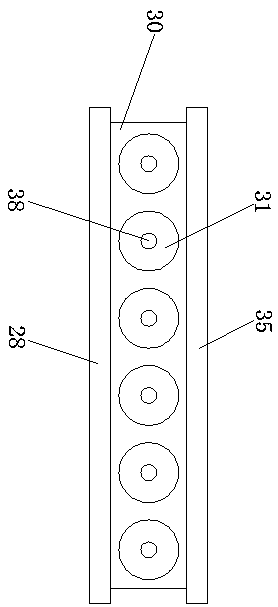

[0028] see Figure 1-6, the present invention provides the following technical solutions: a building construction spraying system and construction method thereof, comprising a mobile trolley 23, a mixing bucket 8 and a scrub brush 31, the top of the mobile trolley 23 is fixedly connected with two slide rails 40, and each The slide rail 40 is provided with a slide block 39, and the tops of the two slide blocks 39 are fixedly connected with a lifting platform 25, and the bottom of the lifting platform 25 is fixedly connected with a moving plate 22, and the front side of the moving plate 22 A threaded sleeve 19 is fixedly connected, the threaded sleeve 19 is internally threaded with a screw rod 21, the top of the mobile trolley 23 is fixedly connected with a third motor 24, and the output shaft of the third motor 24 is fixedly connected with the screw rod 21 , during construction, the third motor 24 can drive the screw rod 21 to rotate in the threaded sleeve 19. Under the action ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com