Two-component water-based woodware paint

A water-based wood lacquer, two-component technology, applied in the field of wood lacquer, can solve the problems of health hazards, reduced negative ion concentration, discomfort, etc., and achieves the effects of large painting area, strong stability and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Acrylic resin: composite nano-bactericidal powder: composite nano-anion powder: polyacrylic acid sodium salt: aliphatic hydrocarbon and emulsifier mixture: polyurethane polymer: ethylene glycol: water: water-based isocyanate = 50: 2.5: 2.5: 1: 0.3: 3:5:25:20 ratio, weigh 50kg of acrylic resin, 2.5kg of composite nano-bactericidal powder, 2.5kg of composite nano-anion, 1kg of polyacrylic acid sodium salt, 0.3kg of aliphatic hydrocarbon and emulsifier mixture, and 3kg of polyurethane polymer , ethylene glycol 5kg, water 25kg, water-based isocyanate 20kg, spare.

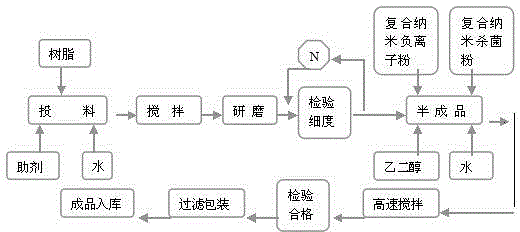

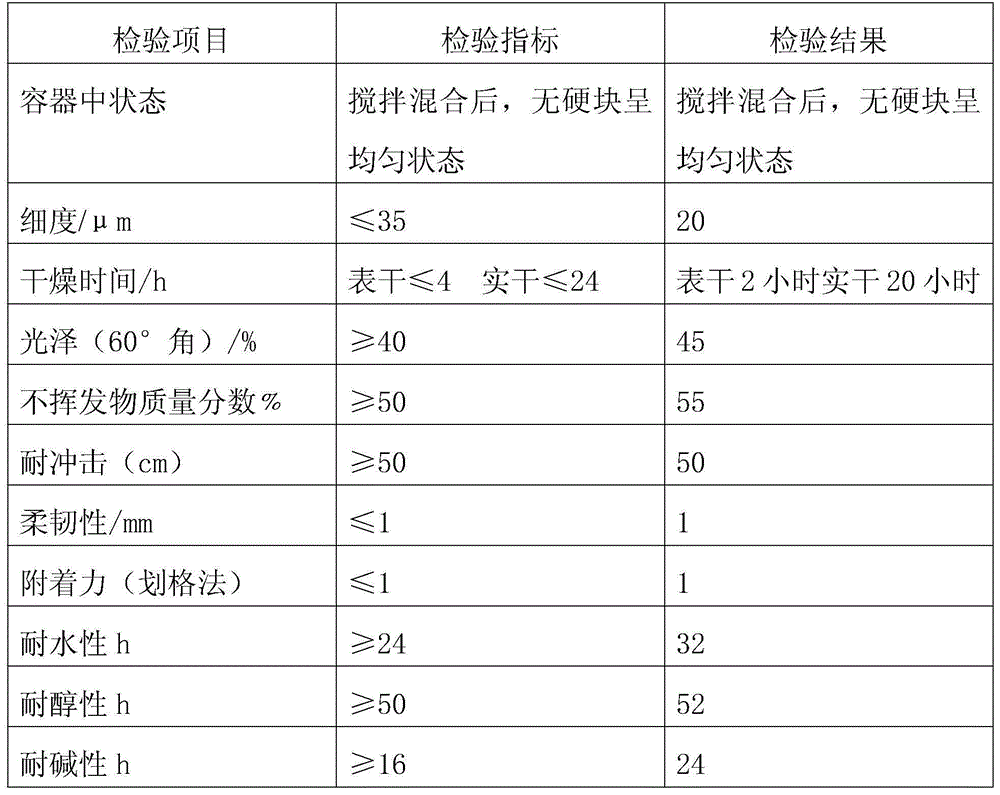

[0029] According to the process formula, acrylic resin, polyacrylic acid sodium salt, aliphatic hydrocarbon and emulsifier mixture, and polyurethane polymer are first added to the stirring tank of the high-speed disperser. After the concentration reaches the standard requirements, it is pumped to the coloring kettle, then add nano-anion powder, nano-bactericidal powder, ethylene glycol, and water to stir, adjust ...

Embodiment 2

[0033] Acrylic resin: composite nano-bactericidal powder: composite nano-anion powder: polyacrylic acid sodium salt: aliphatic hydrocarbon and emulsifier mixture: polyurethane polymer: ethylene glycol: water: water-based isocyanate = 60:5:3:2:1: 4:6:15:25 ratio, respectively weigh 60kg of acrylic resin, 5kg of composite nano-sterilizing powder, 3kg of composite nano-anion, 2kg of polyacrylic acid sodium salt, 1kg of aliphatic hydrocarbon and emulsifying agent mixture, 4kg of polyurethane polymer, Ethylene glycol 6kg, water 15kg, water-based isocyanate 25kg, spare.

[0034] According to the process formula, acrylic resin, polyacrylic acid sodium salt, aliphatic hydrocarbon and emulsifier mixture, and polyurethane polymer are first added to the stirring tank of the high-speed disperser. After the concentration reaches the standard requirements, it is pumped to the coloring kettle, then add nano-anion powder, nano-bactericidal powder, ethylene glycol, and water to stir, adjust th...

Embodiment 3

[0038] Acrylic resin: composite nano-bactericidal powder: composite nano-anion: polyacrylic acid sodium salt: aliphatic hydrocarbon and emulsifier mixture: polyurethane polymer: ethylene glycol: water: water-based isocyanate = 80: 10: 5: 5: 2: 6 : 10:10:50 ratio, weigh 80kg of acrylic resin, 10kg of composite nano-sterilizing powder, 5kg of composite nano-anion, 5kg of polyacrylic acid sodium salt, 2kg of aliphatic hydrocarbon and emulsifier mixture, 6kg of polyurethane polymer, ethylene glycol Alcohol 10kg, water 10kg, water-based isocyanate 50kg, spare.

[0039] According to the process formula, acrylic resin, polyacrylic acid sodium salt, mixture of aliphatic hydrocarbon and emulsifying agent, and polyurethane polymer are first added to the stirring tank of the high-speed disperser, and after stirring and mixing evenly, the pump is sent to a sand mill or a ball mill for further grinding. After checking that the fineness meets the standard requirements, pump it to the colori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com