Apparatus for tow opening

A device, technology of tow, applied in the field of equipment for unraveling tow, capable of solving problems such as having to be replaced periodically, differences in tow, and rubber rollers susceptible to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A multifilament tow as used herein refers to any tow having a total denier of less than 200,000, especially 100,000 or less. The fiber tow may comprise any synthetic polymer tow such as, for example, polyolefins (e.g., polyethylene, polypropylene), polyesters (e.g., PET, PBT), cellulosics (e.g., rayon, cellulose esters (e.g., cellulose acetate), ) cellulose ether), preferably cellulose acetate tow.

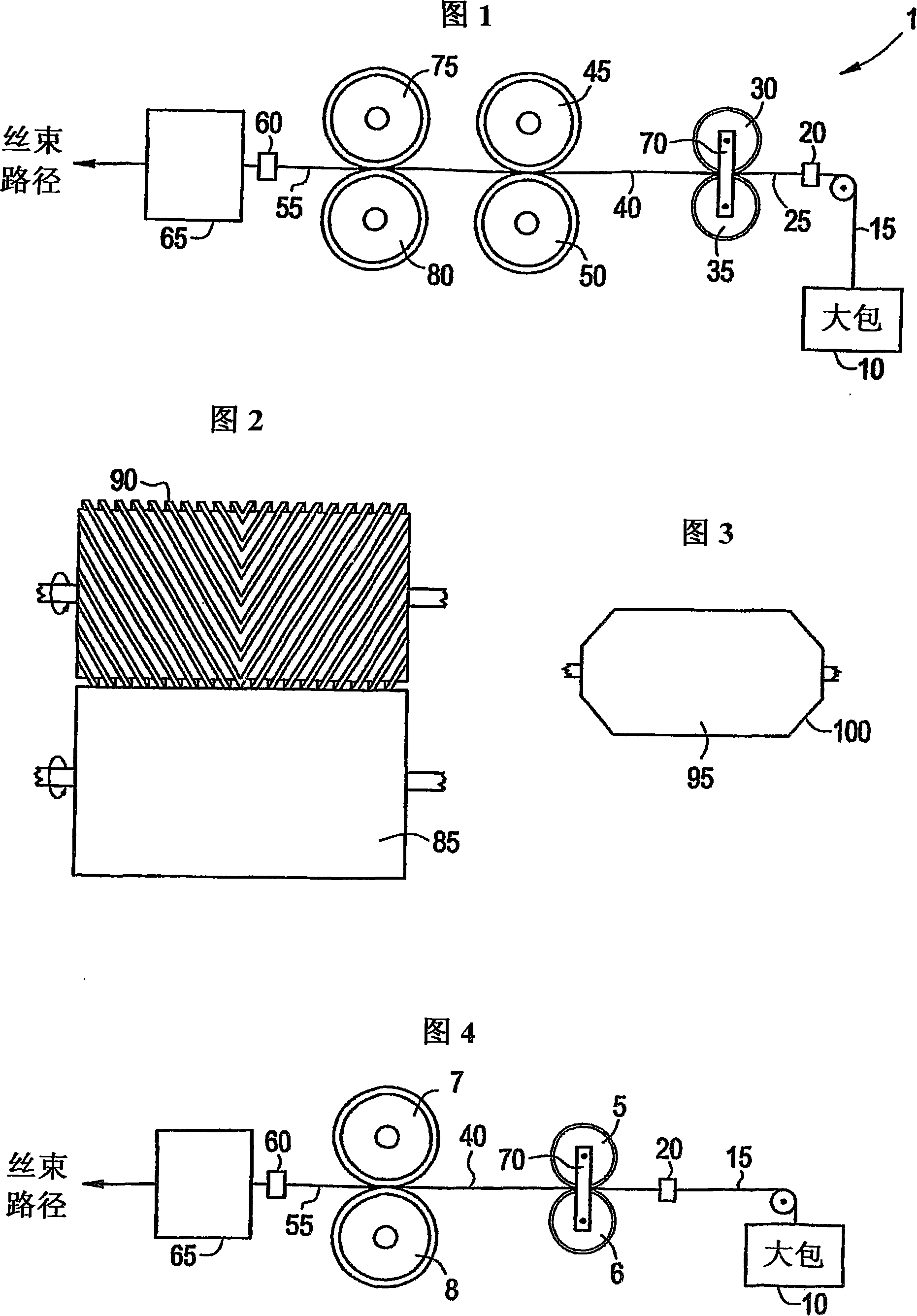

[0016] Referring now to the drawings, in which like reference numerals indicate like elements, there is shown in Figure 1 a tow unwinding device 1 . Device 1 comprises belt nozzle 20, a pair of tension rollers 30,35, a pair of first unraveling rollers (delivery rollers) 45,50, a pair of second unraveling rollers (proportional rollers) 75,80, the second belt nozzle 60 And optional applicator 65.

[0017] The tow 15 is drawn from the bale 10 by the first pair of unwinding rollers 45 , 50 via the belt nozzle 20 and the tension rollers 30 , 35 . The tow is then fed from the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com