Device and method for the automatic pick-up of fibre from a bale of fibre on a spinning line

A technology for picking up equipment and fibers, which can be used in fiber unpacking, fiber processing, textiles and papermaking, etc., and can solve problems such as different fiber densities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

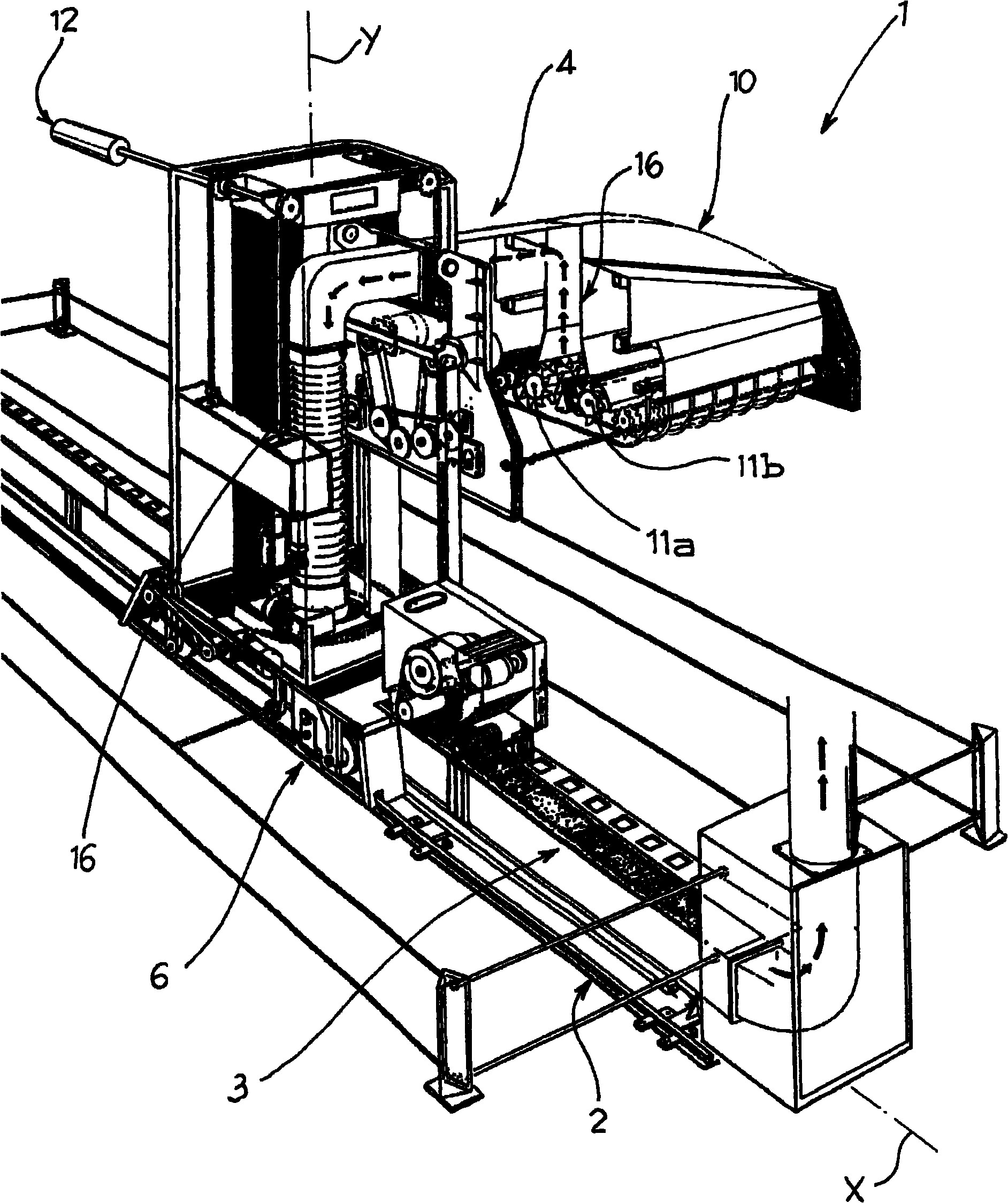

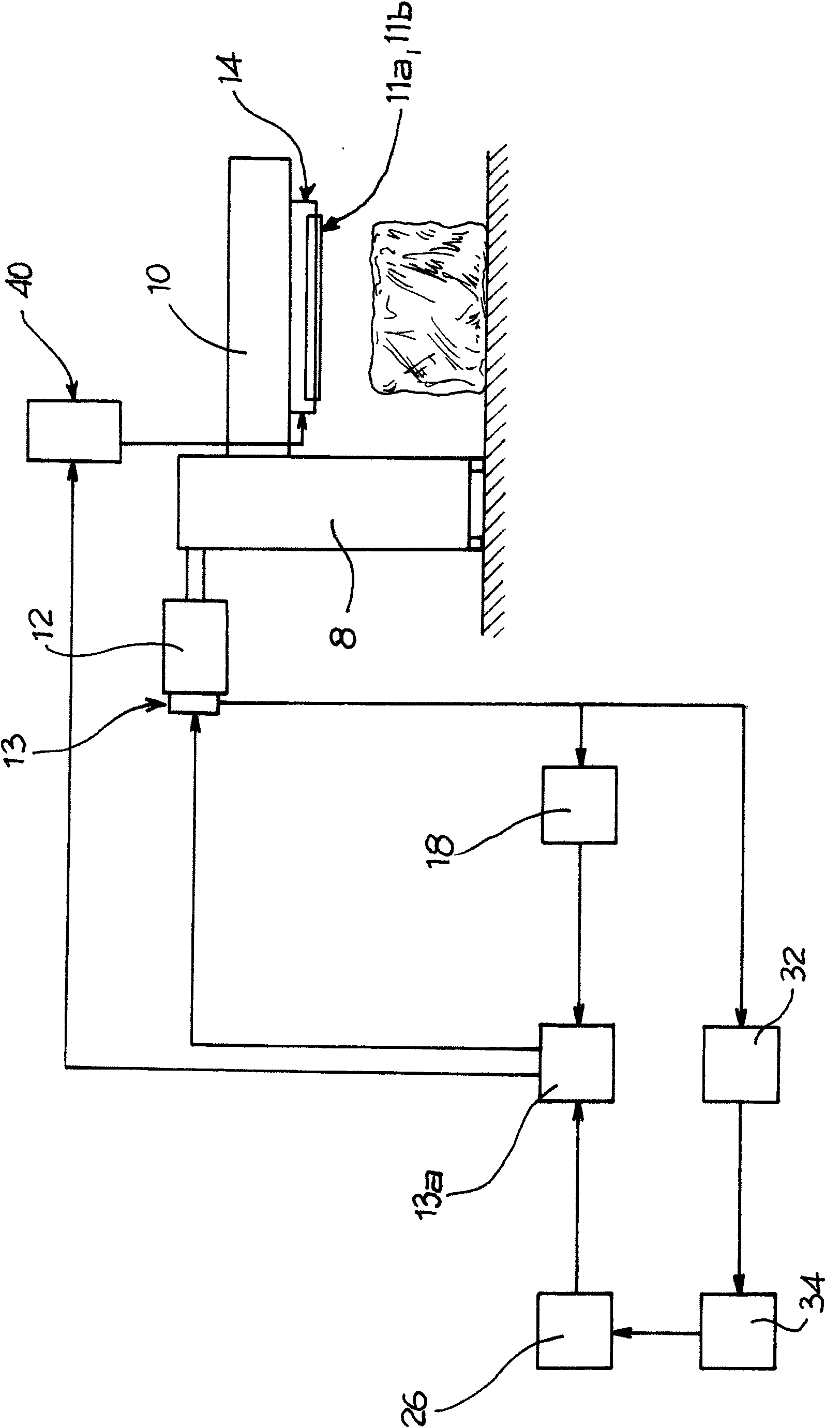

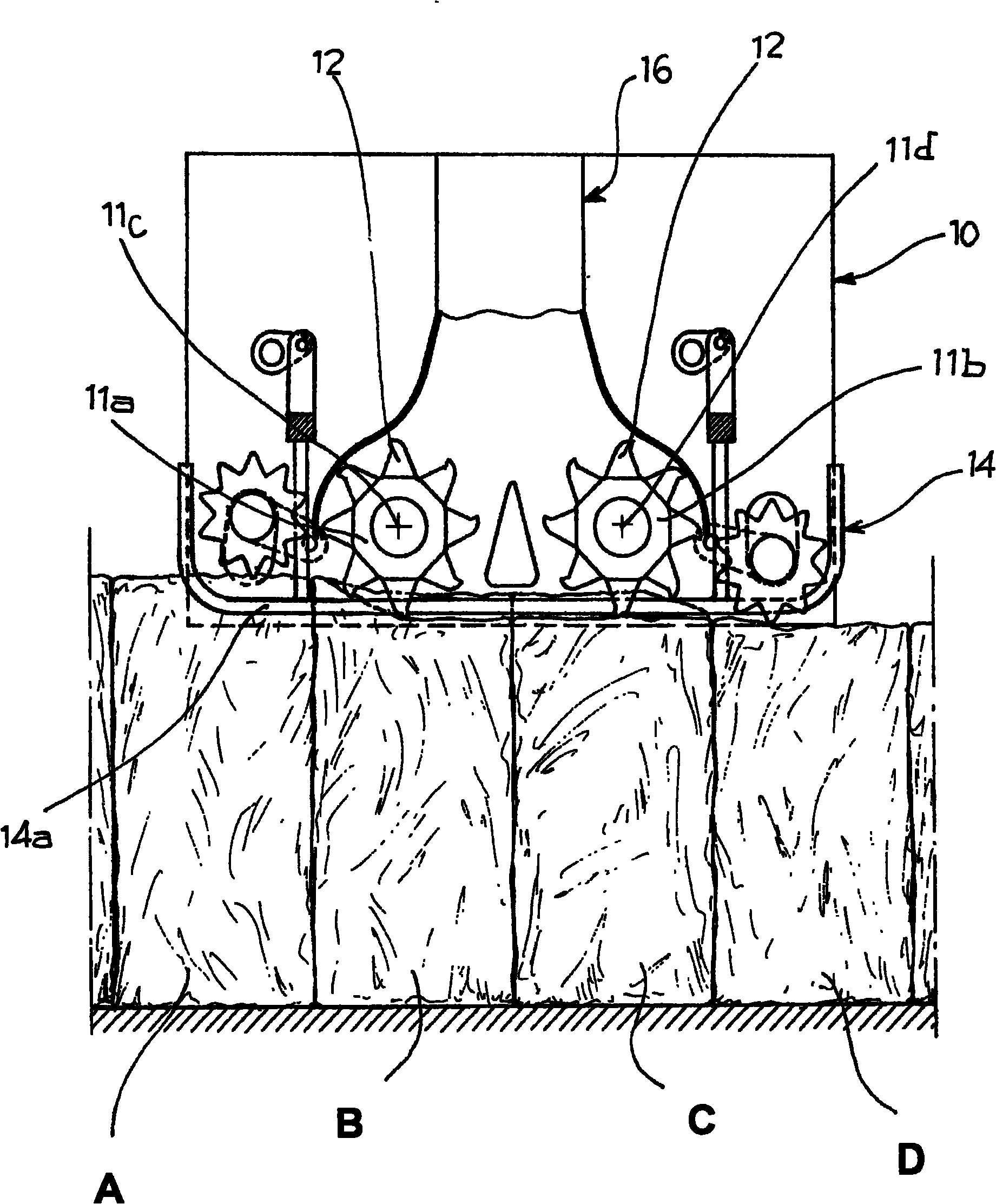

[0033] Referring to the drawings, reference numeral 1 generally designates a pick-up unit on a fiber production line.

[0034] The unit 1 comprises a rail 2 having an extension along the axis X of translation. The bales of fibers are positioned along the track 2 , along one or both sides of said track, sometimes continuously and sometimes spaced apart from each other. Such bales occupy a pick-up area on the ground next to track 2 .

[0035] Preferably, the unit 1 comprises a discharge duct 3 in communication with other equipment located downstream of the pick-up equipment, performing subsequent processes or vacuuming. For example, this discharge duct 3 is positioned between the rails of the track 2 .

[0036] The unit 1 also comprises a pick-up device 4 placed on the track 2 and able to translate along the track 2 upon command.

[0037] In particular, this device 4 comprises a carriage 6 , for example equipped with wheels, placed on the rail 2 , and a strut 8 , having an ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com