Reinforced nonwoven fabric

A technology for textile structures and articles, applied in the field of carbon fiber non-woven fabrics, can solve problems such as impact, harmful strength-to-weight ratio, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

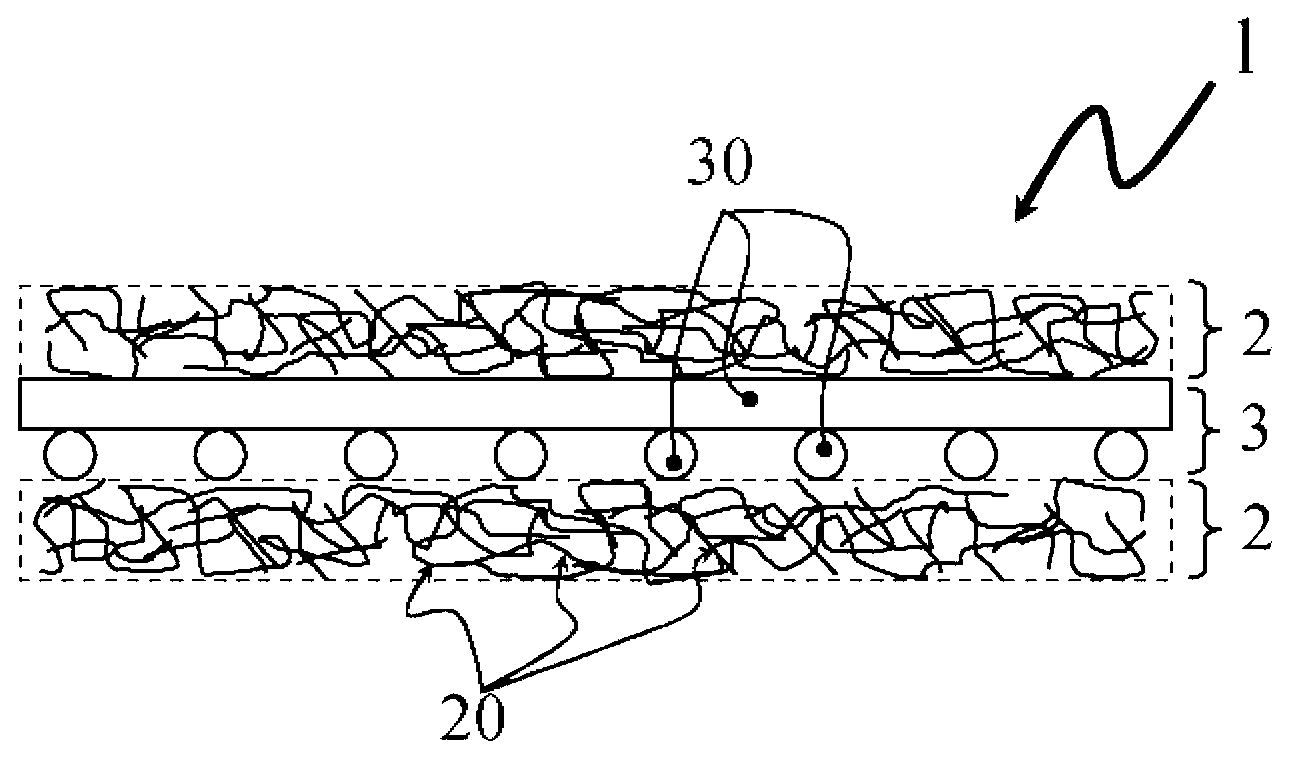

[0024] figure 1 A schematic structural design of a flat textile structure ( 1 ) according to one aspect of the invention is shown. A reinforcement mesh (3) according to the invention is fixed here between two pile layers (2) according to the invention, said reinforcement mesh (3) as represented by its mesh braces (30) , the pile layer (2) as represented by its fibers (20).

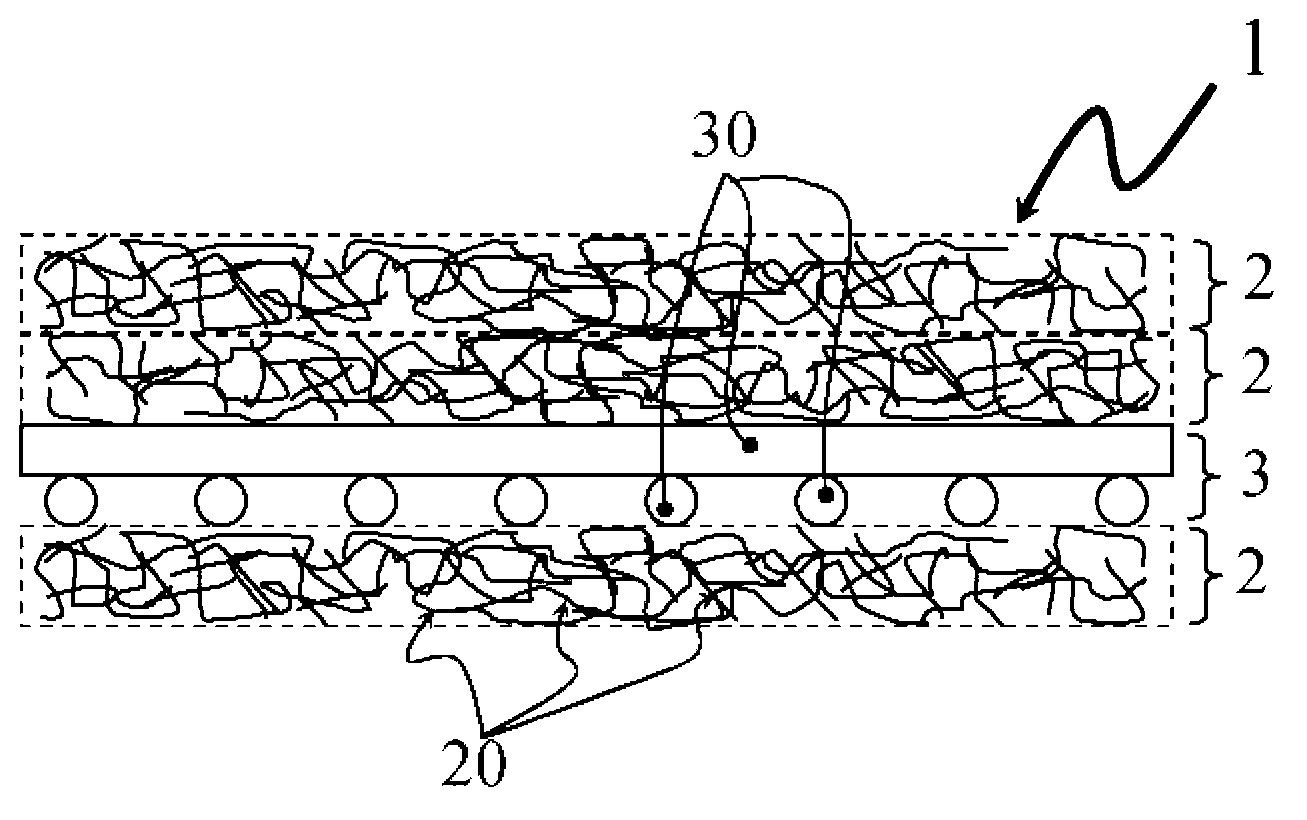

[0025] figure 2 A schematic structural design of a preferred embodiment of a flat textile structure ( 1 ) according to the invention is shown. Two vertically stacked pile layers ( 2 ) are here on one side of the reinforcement grid ( 3 ), and one pile layer ( 2 ) on the other side. This embodiment is preferred because the surface of the planar textile structure ( 1 ) exhibits better optical and tactile properties on the side with the two vertically stacked pile layers ( 2 ). This becomes advantageous mainly when only one side of the part is visible in the rear part integrally forming the planar textile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com