Method and assembly for processing round seed cotton modules

A technology of assembly and working state, applied in the field of assembly for removing seed cotton, assembly of modules, processing seed cotton modules so that the equipment removes plastic sheath, and the field of devices for seed cotton modules, which can solve high maintenance and operating costs, structural complex issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Although the invention will be described with reference to its application in cotton processing, those skilled in the art will appreciate that the components described below in accordance with the various embodiments may be suitable for use in other applications.

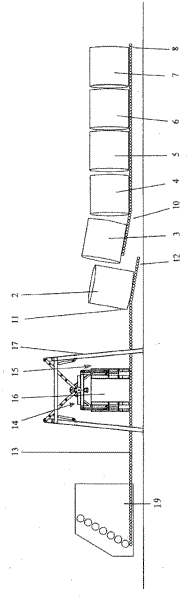

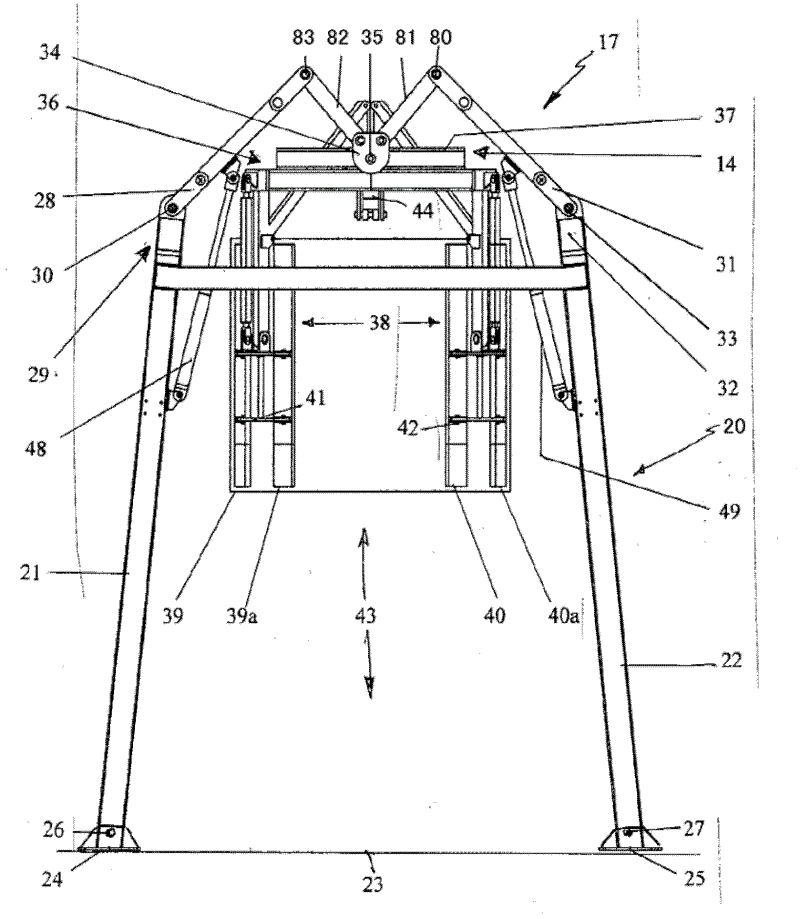

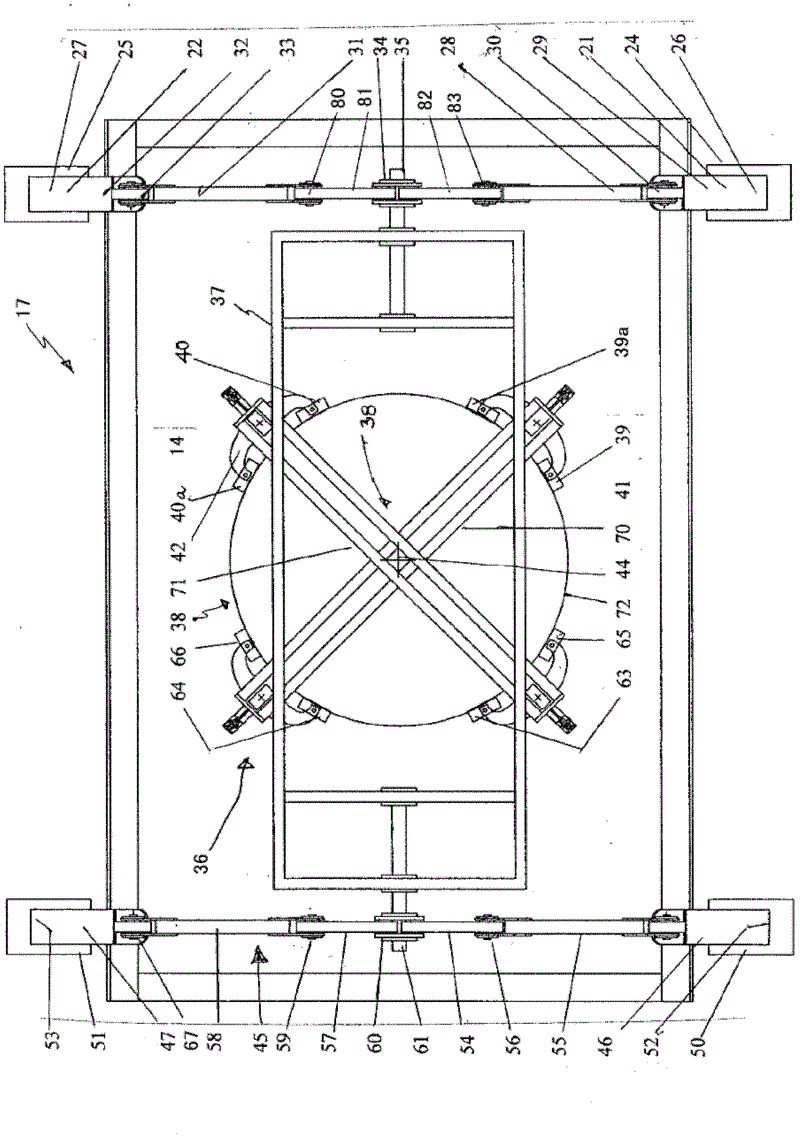

[0055] figure 1 A side view of the conveyor belt processing system 1 is shown with the bales 2 , 3 , 4 , 5 , 6 and 7 advancing along the first conveyor belt 8 towards the device 17 . Typically, bales of roundseed cotton, also described as modules, are packed using a plastic sheath that is tightly wrapped around the modules, usually leaving open ends. Roundseed cotton modules can weigh up to three tons, so mechanical devices must be used to handle the modules. When wrapping the module, the seed cotton is surrounded under the action of circumferential compressive force caused by the tension in the plastic sheath. The round seed cotton modules are generally cylindrical so that the plastic sheath forms the wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com