Bamboo fiber mattress core material and production process thereof

A production process, bamboo fiber technology, applied in mattresses, spring mattresses, fiber cleaning and other directions, can solve the problems of long production process, unstable product quality, environmental pollution, etc., and achieve the effect of stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

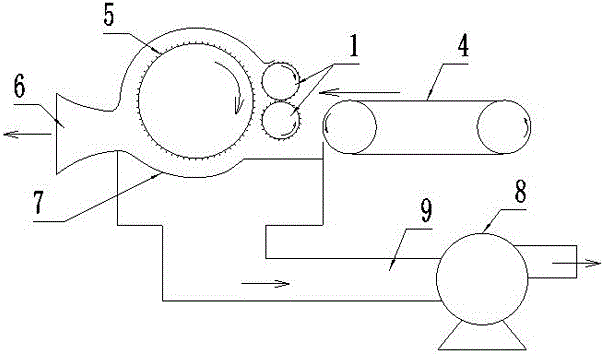

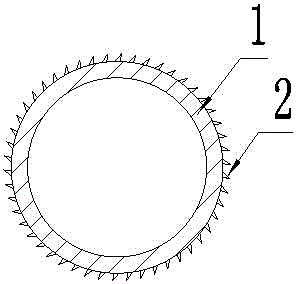

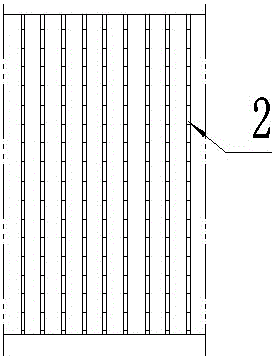

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] A bamboo fiber mattress core material, comprising bamboo fiber, polyester staple fiber and polyester fiber, the moisture content of the bamboo fiber is 10% to 15%, and the weight percentages of each component are as follows: bamboo fiber 65 to 75%, polyester fiber Short fiber 5-15, polyester fiber 20-25; made by mixing, carding, laying, baking and pressing.

[0028] Wherein, the polyester staple fiber is a 4D polyester staple fiber, and the polyester fiber is a low melting point fiber.

[0029] The present invention also provides the production technology of above-mentioned bamboo fiber mattress core material, and concrete steps are as follows:

[0030] (1) Raw material preparation and mixing: After the bamboo fiber, polyester staple fiber and polyester fiber are measured in proportion, enter the bale opener for full mixing; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com