Pile layer having curved bundles

A fiber bundle, plush technology, applied in the field of plush layer, can solve problems such as damage to plush layer, cost generation, etc., and achieve the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

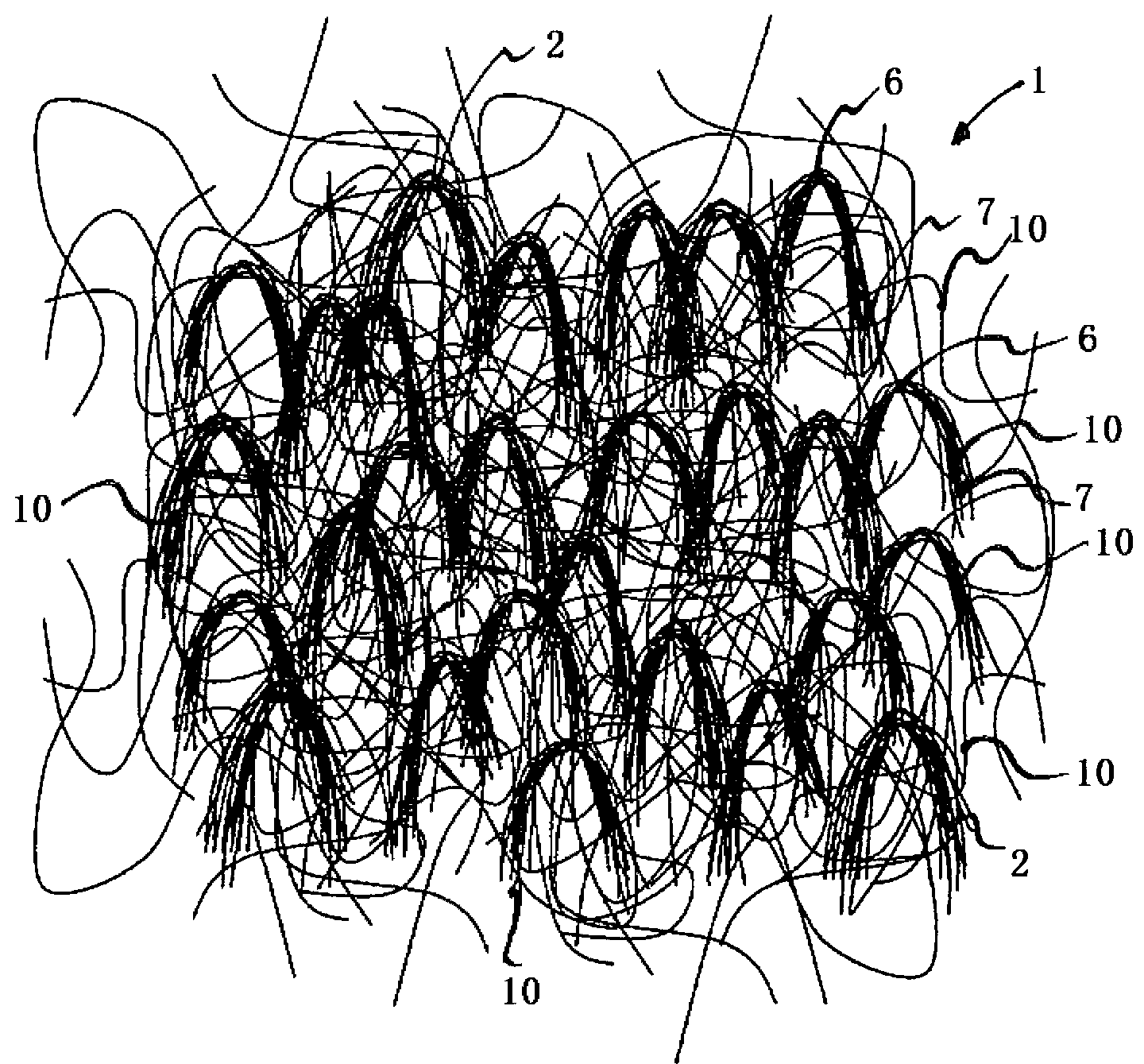

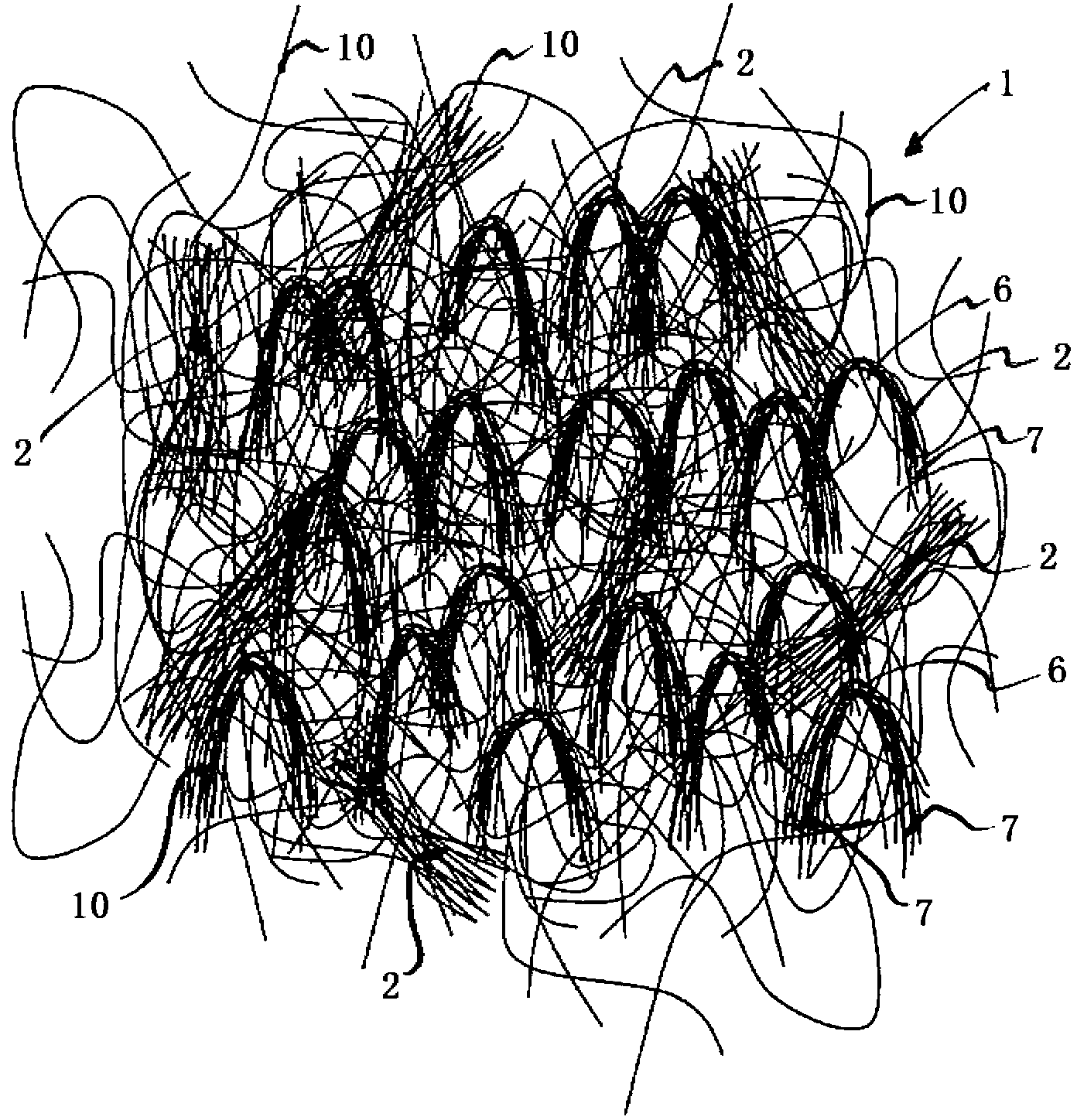

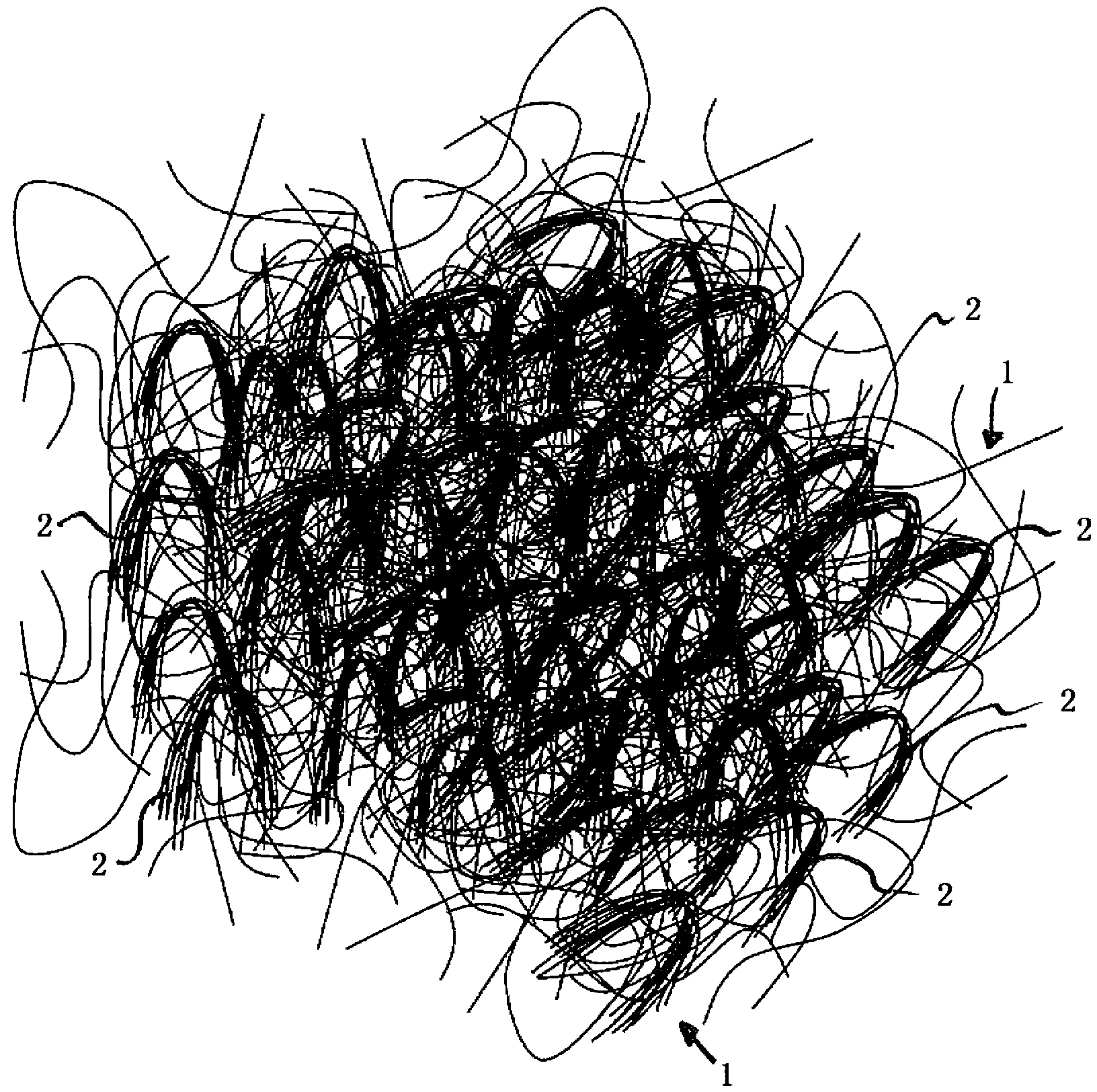

[0063] figure 1 A first embodiment of a pile layer 1 according to the invention with a plurality of fiber bundles 2 comprising carbon fibers 10 is shown. The fiber bundles 2 each exhibit an apex region 6 and two fiber bundle end regions 7 . exist image 3 The terms apex region 6 and fiber bundle end region 7 are explained in more detail above.

[0064] It is evident that a plurality of bent fiber bundles 2 are anchored in the fleece layer 1 by means of separated fibers. The fibers can here be contained partly by the fleece layer 2 and partly by the bent fiber bundles 2 . The fleece layer 2 thus consists of entangled fibers which are either not contained or are partially or completely contained by the bent fiber bundles 2 . In this way, entanglement of the fibers makes it possible to create a planar structure, i.e. a pile layer 1, which is sufficiently stable during exposure to external mechanical influences to be further processed, for example during subsequent handling ....

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com