Blowing-carding electrical control system and control method

An electrical control system, the technology of blowing and carding, applied in electrical program control, comprehensive factory control, textile and papermaking, etc., can solve the problems of unstable system operation, difficult to grasp the proportional coefficient and integration time, etc. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

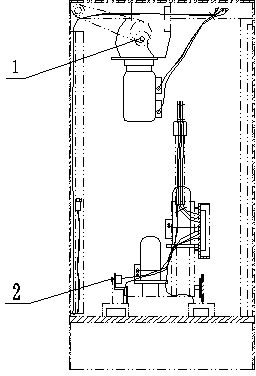

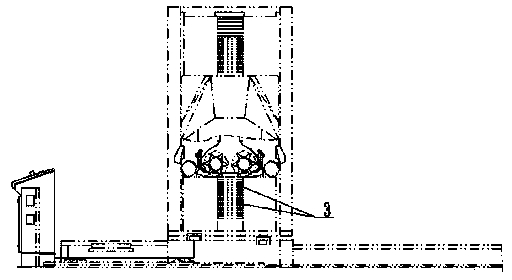

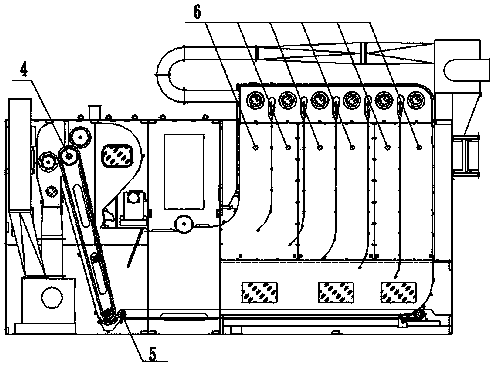

[0027] see Figure 1-Figure 5 , an embodiment of a blowing and carding electrical control system of the present invention, comprising: a cotton catching machine, a cotton opener, a multi-storey cotton blending machine, a cleaning machine, a cotton pipeline, a carding machine, a fan, a gold fire detector, a Micro dust machine, sensor and control system. The above-mentioned control system includes: a central controller, a human-machine interface, and the sensors include: a walking speed sensor 2 of the cotton picking machine (the prior art, installed on the output shaft of the walking motor reducer), a cotton picking depth sensor 1 (the prior art , installed on the output shaft of the lifting motor reducer), the cotton mixing pipeline pressure sensor 3, the cotton mixing warehouse level sensor 6, the inclined curtain speed sensor 4 of the cotton mixing ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com