Petroleum pipeline cleaning device

A technology for oil pipelines and cleaning devices, applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of poor flexibility, weak cleaning strength, poor cleaning effect of cleaning devices, etc. The effect of avoiding cleaning dead corners, improving the load capacity and the ability to overcome obstacles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The implementation of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present application uses technical means to solve technical problems and achieve technical effects.

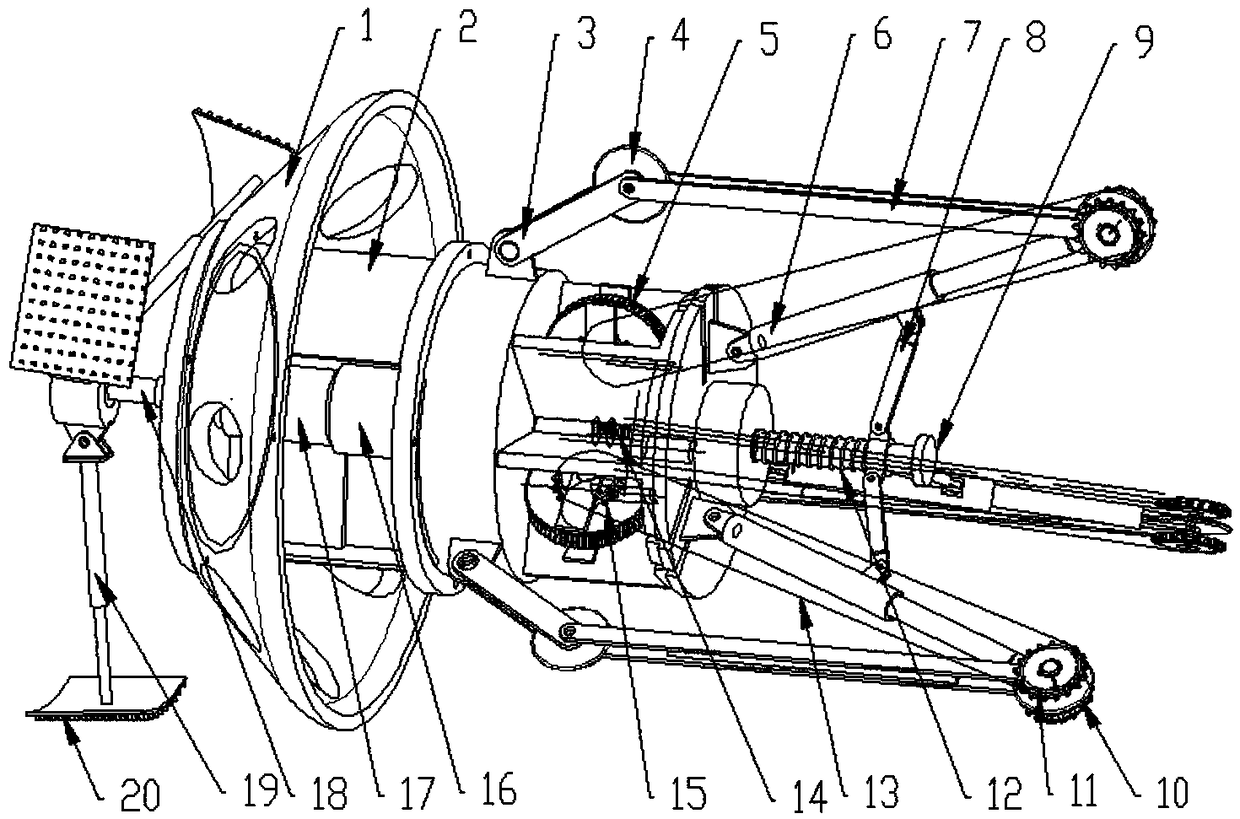

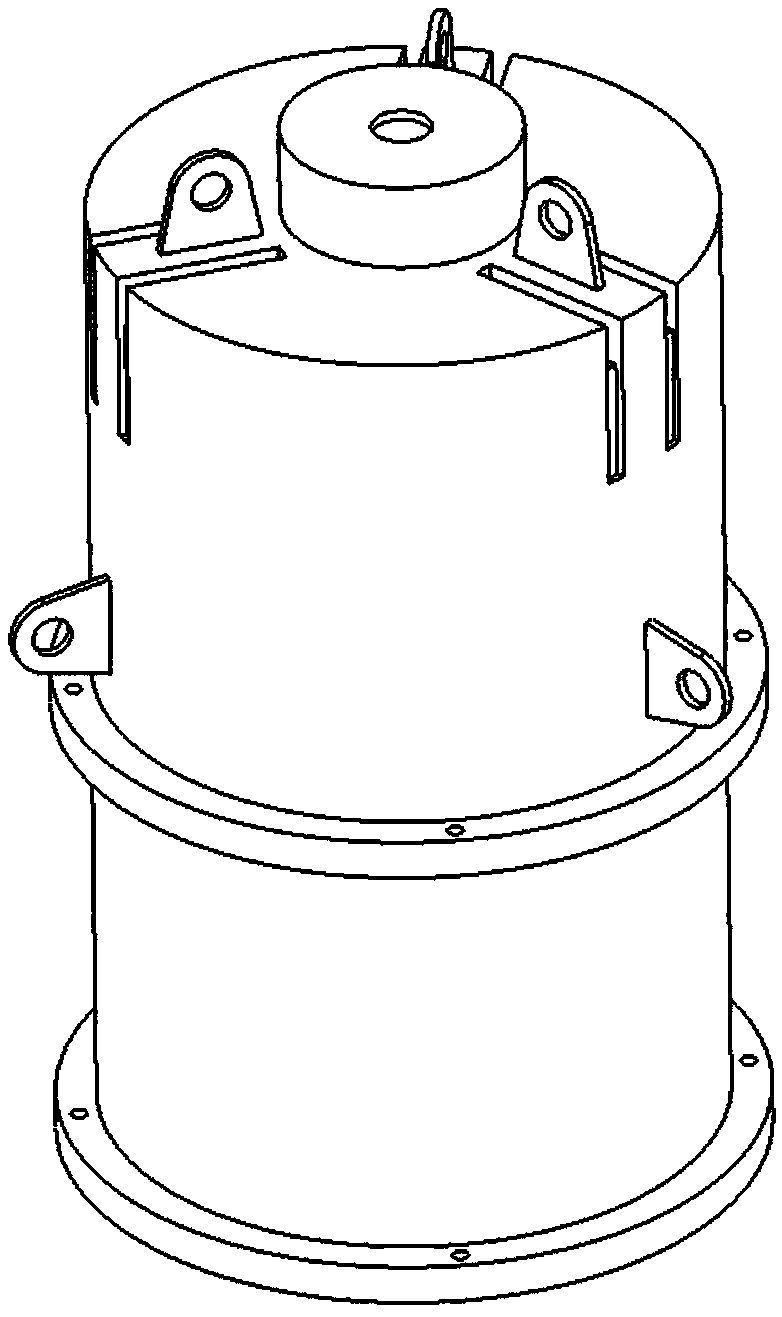

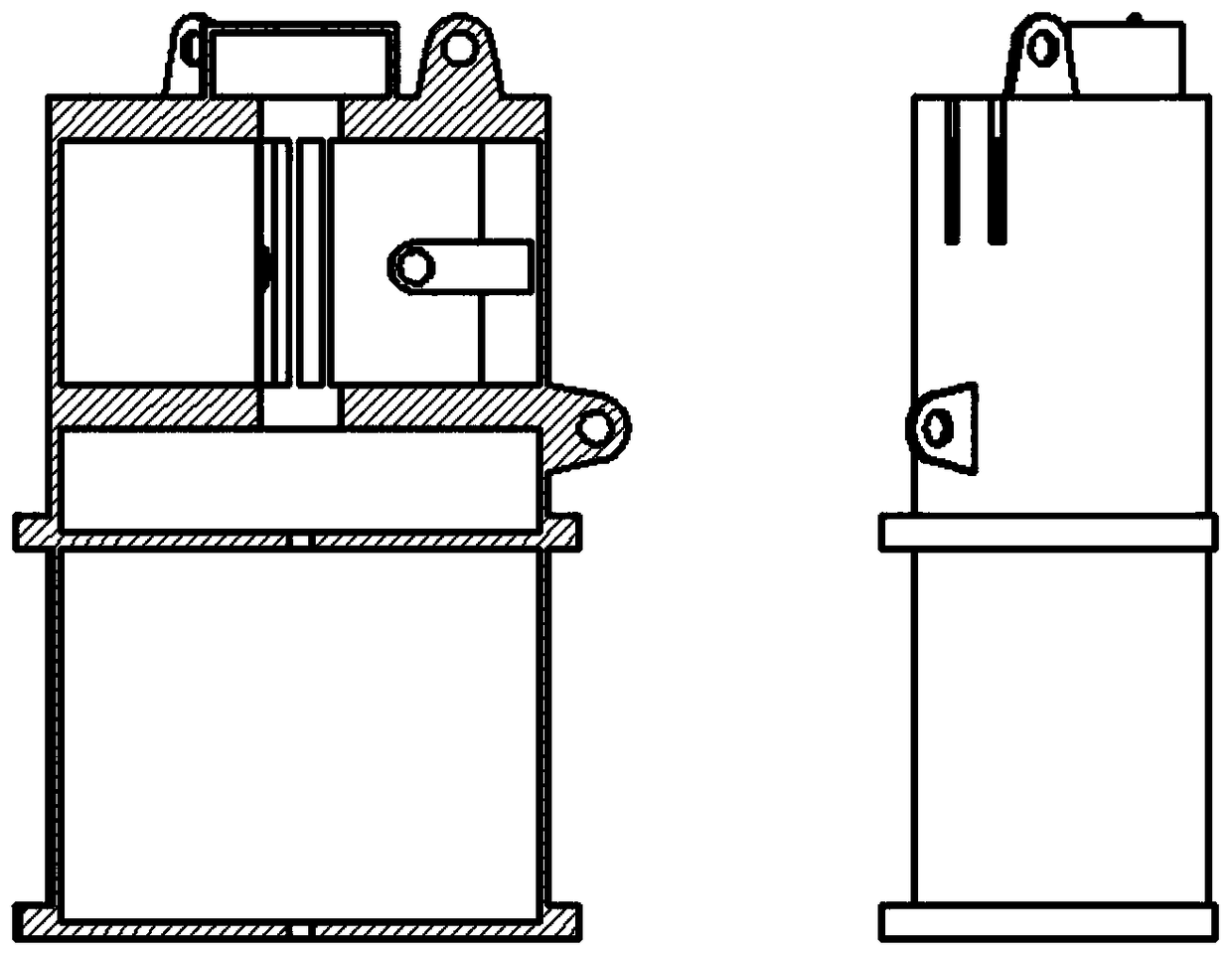

[0032] like figure 1 As shown, a petroleum pipeline cleaning device of the present invention is composed of a driving system, a transmission system, a walking system and a cleaning system, and specifically includes a leather cup 1, a casing 2, a crank 3, a driven traveling wheel 4, a worm wheel 5, and a second compressor Barrel 6, connecting rod 7, adjusting connecting rod 8, adjusting bolt 9, driving wheel 10, driven sprocket 11, adjusting spring 12, chain 13, worm 14, driving sprocket 15, motor 16, reducer 17, Cleaning shaft 18, first compression cylinder rod 19, and cleaning plate 20. The output end of the motor 16 is connected with the worm screw 15, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com