Disc plucker

The technology of a disc grabbing machine and a cotton hopper is applied in the field of textile machinery, which can solve the problems of low efficiency, easy blockage of the cotton hopper, cumbersome structure, etc., and achieves the effects of convenient operation, simple structure, and easy blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

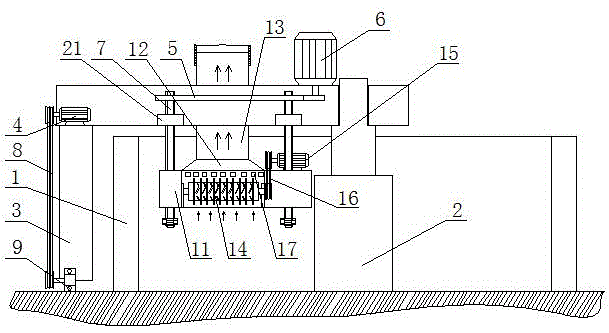

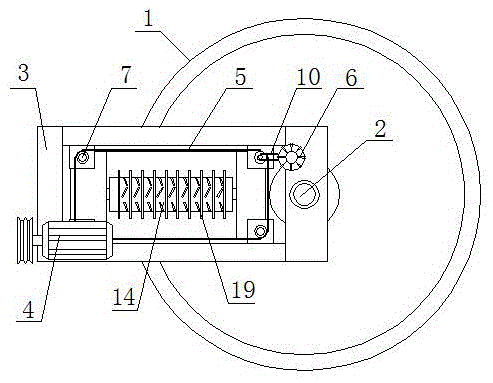

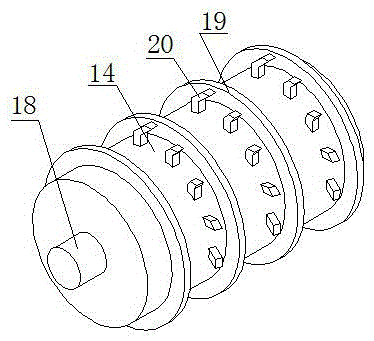

[0016] The disc plucking machine is composed of a silo 1, a central column 2, a drive stand 3, a drive motor 4, a drive wheel 9, a transmission motor 6, a transmission screw 7 and a cotton collection device; the circular silo 1 center The center column 2 is installed in the position; the drive stand 3 with an "L" shape in the cross section is movable on the center column 2; one end of the drive stand 3 extends to the outside of the silo 1; The drive wheel 9 is equipped with at the bottom of the frame 3; the drive wheel 9 is rollingly connected with the ground. Drive motor 4 is housed on the drive stand 3 above drive wheel 9; Drive motor 4 is connected with drive wheel 9 by transmission belt A8.

[0017] The drive stand 3 on one side of the central column 2 is equipped with a drive motor 6, and the drive stand 3 below the drive motor 6 is equipped with a drive screw 7 through a bearing seat 21; the drive motor 6 is connected with the drive screw 7 through a transmission belt B1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com