Blowing carding intelligent remote control system and control method thereof

A remote control system, cleaning and carding technology, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve problems that affect the effective control of the system, abnormal system operation, analysis improvement, etc., to achieve stable product quality and realize The effect of remote monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

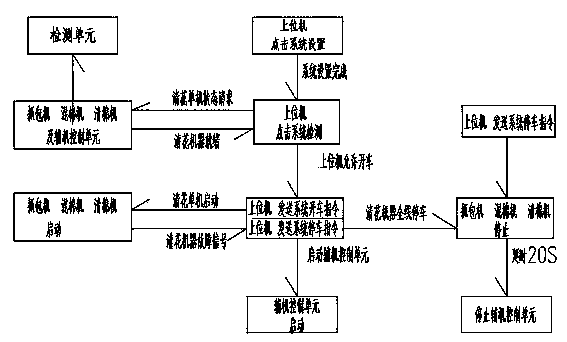

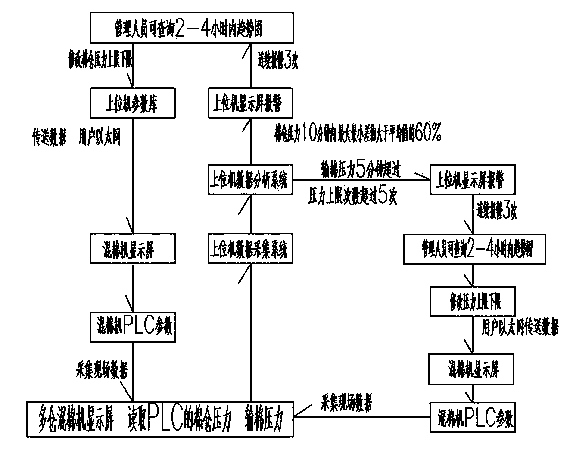

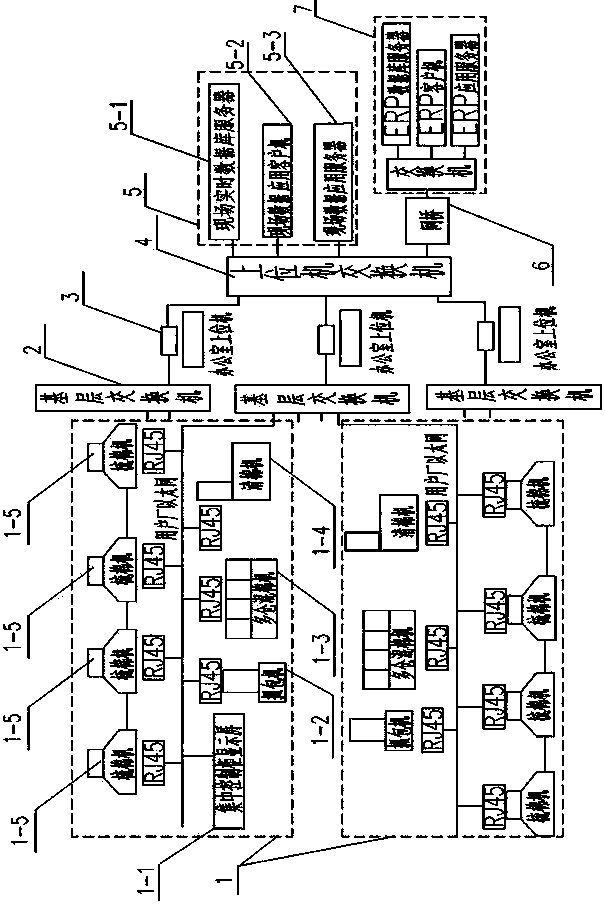

[0019] see figure 1 , an embodiment of a blowing and carding intelligent remote control system of the present invention, comprising a cotton picking machine 1-2, a cotton opening machine 1-3, a multi-bin cotton mixing machine 1-4, a cotton cleaning machine 1-5, a carding machine Blowing-carding equipment and control system composed of machine 1-6, auxiliary machine fan, gold fire detector, and dust remover. The control system includes controllers and man-machine interfaces of each stand-alone plucking machine 1-2, cotton opener 1-3, multi-bin cotton blending machine 1-4, cotton cleaning machine 1-5 and carding machine 1-6 , basic switch 2, office host computer 3, host switch 4, database server 5. The controllers and human-machine interfaces of the above-mentioned stand-alone machines are all equipped with industrial Ethernet interfaces, and the industr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com