A device and method for quickly formulating process parameters of resin-based composite materials

A composite material and molding process technology, applied in the field of modularized integrated equipment, can solve the problems of no application cases, etc., achieve the effect of reducing the number of tests and cycles, easy disassembly and installation, and compensation for large deviations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

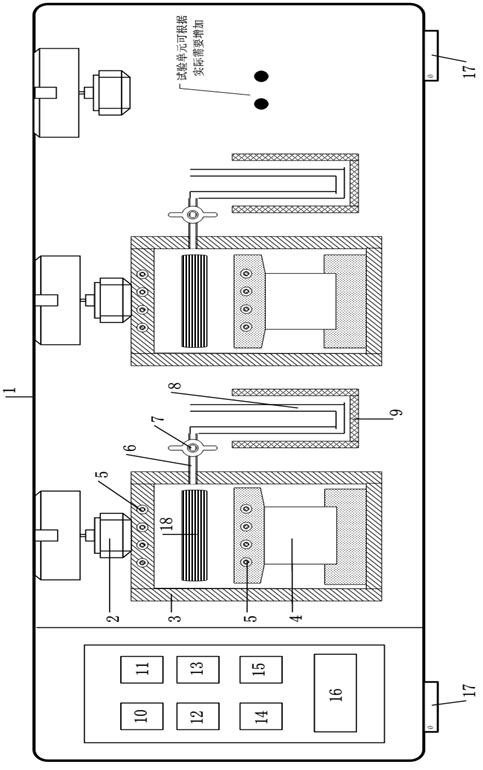

[0064] In this embodiment, the equipment for rapidly setting the molding process parameters of the resin-based composite material is used to formulate the molding process parameters of the high-temperature-resistant polyimide resin-based composite material, and the specific steps are as follows:

[0065] The first step: determine the resin matrix composite material process parameters to be screened for the polyimide resin matrix composite material: target temperature, heating and cooling rate, holding temperature, curing temperature, pressurization temperature, pressure, vacuum degree, a total of 7;

[0066] The second step: according to the determined seven process parameters of the polyimide resin matrix composite material, install the corresponding seven groups of test unit devices in the integrated combined box;

[0067] The third step: put the pre-cured polyimide resin-based composite material used in the test into the vacuum tank 3;

[0068] The fourth step: start the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com