Microwave-assisted rock breaking device and method for simulating moon-based environment drilling process

A microwave-assisted, rock-breaking device technology is applied in earth-moving drilling, application of thermal energy drilling, wellbore/well components, etc., to achieve the effect of good effect, high heating efficiency, and real-time data acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

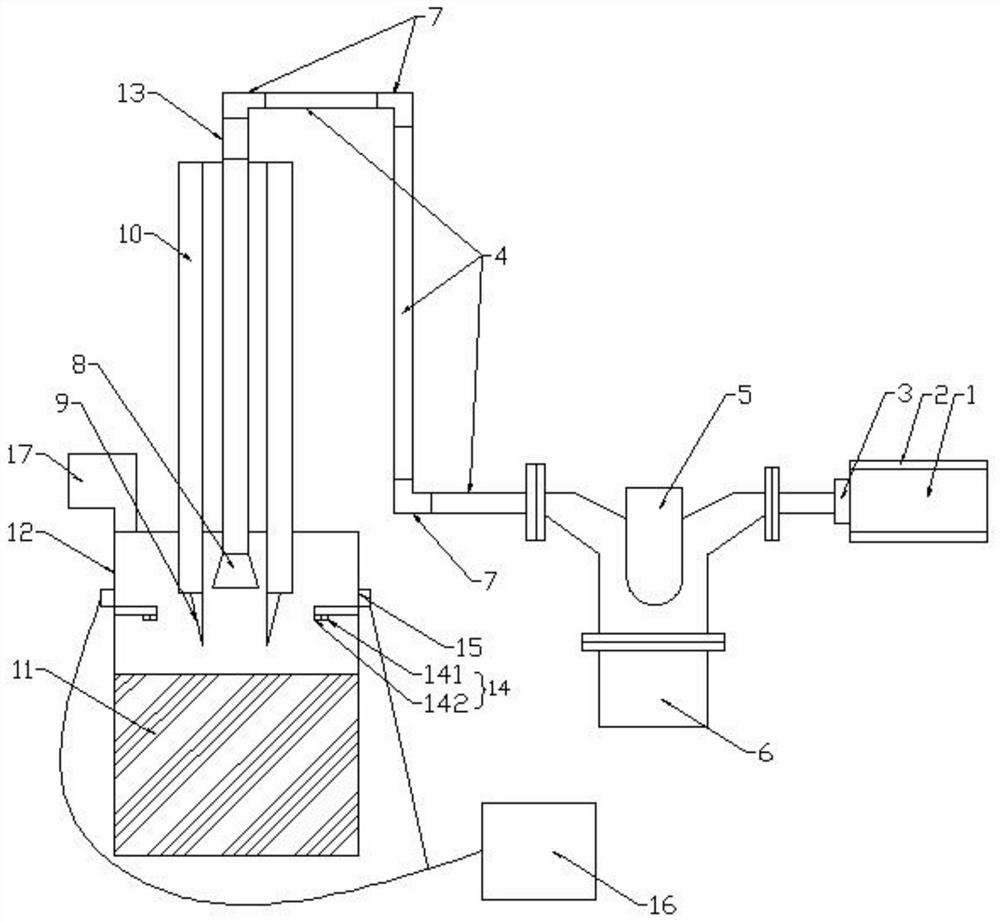

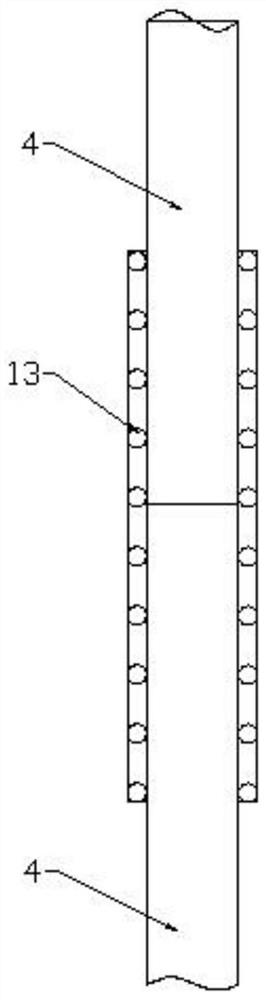

[0041] Such as Figure 1-Figure 2 As shown, a microwave-assisted rock-breaking device for simulating the drilling process of the moon-based environment, a microwave-assisted rock-breaking device for simulating the drilling process of the moon-based environment includes: a core barrel 12, a lunar imitation vacuum module 17, a microwave module, a drilling Module and data acquisition module; the rock 11 to be broken is placed in the core barrel 12, and rocks with different materials and different hardness and other physical properties can be selected in the experiment to simulate different lunar rock materials.

[0042] The moon-like vacuum module 17 is arranged outside the core barrel, and is used to evacuate the inside of the core barrel 12 to simulate the moon-based environment. Generally, a vacuum extraction device is used for vacuuming. In order to maintain the vacuum environment in the core barrel 12, the rock The core barrel 12 is a vacuum-tight container capable of withst...

Embodiment 2

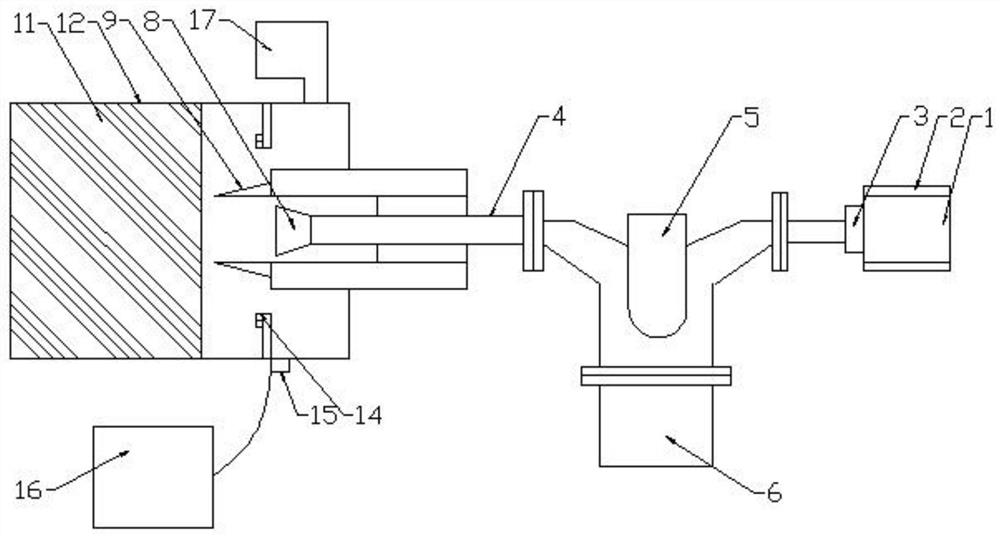

[0057] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the microwave module and the drilling module are all arranged on the right side of the core barrel 12, the microwave feed port 8 irradiates the rock from the right side, and the cutting teeth 9 drill from the right side. Rock 11 and sampled. In this way, the magnetron 1 is facing the microwave feed port 8, and the magnetron 1 is connected with the input port of the circulator 5 through the rectangular waveguide 3, and the output port of the circulator 5 is connected with the coaxial waveguide 4, and the coaxial waveguide 4 extends into the rock core The barrel 12 is connected to the microwave feed port 8, and the waveguide converter 7 is not needed to convert the transmission direction of the microwave.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com