High-activity crystal seed for concrete production and preparation method thereof

A concrete, high-activity technology, applied in the field of building materials, can solve the problems of poor later strength delay, poor durability, and instant concrete setting, so as to improve the speed and activity of seed crystal formation, and improve the quality and quantity. , the effect of reducing production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

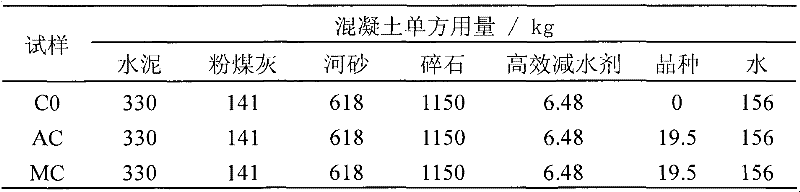

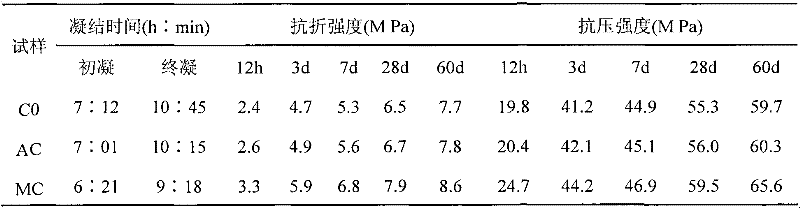

Examples

Embodiment 1

[0028] Embodiment 1: a kind of preparation method of high activity crystal seed for concrete production, comprises the steps:

[0029] 1) Preparation of waste ceramic powder: The finished waste ceramics discharged from daily life are processed according to the preparation process of screening, water washing, drying, crushing and mechanical grinding. The mud content is 0.5%, paper chips, wood chips, etc. The content of debris is less than 1%, the moisture content is 0.5-0.8%, and the specific surface area of Brinell is 300m 2 / kg, get waste ceramic powder, spare;

[0030] 2) Preparation of pre-ground calcium carbide slag powder: the calcium carbide slag discharged from acetylene production enterprises is prepared by dry method, dried in the sun and ground by vibration mill, and the moisture content of the calcium carbide slag powder after drying and grinding is 1%, Brinell specific surface area 350m 2 / kg, its Ca(OH) 2 Content greater than 70%, f-CaO content 1.5%, SO 3 If...

Embodiment 2

[0043] Embodiment 2: a kind of preparation method of the highly active crystal seed for concrete production, comprises the steps:

[0044] 1) Preparation of waste ceramic powder: The waste ceramics discharged from daily life are processed according to the preparation procedures of screening, water washing, drying, crushing and mechanical grinding. The content of other impurities is less than 1%, the moisture content is 0.2%, and the specific surface area of Brinell is 280m 2 / kg, get waste ceramic powder, spare;

[0045] 2) Preparation of pre-ground calcium carbide slag powder: the calcium carbide slag discharged from acetylene production enterprises is prepared by dry method, dried in the sun and ground by vibration mill, and the moisture content of the calcium carbide slag powder after drying and grinding is 1%, Brinell specific surface area 300m 2 / kg, its Ca(OH) 2 Content 80%, f-CaO content less than 2.5%, SO 3 If the content is less than 2%, the calcium carbide slag...

Embodiment 3

[0049] Embodiment 3: a kind of preparation method of the high activity crystal seed that is used for concrete production, comprises the steps:

[0050] 1) Preparation of waste ceramic powder: The waste ceramics discharged from daily life are processed according to the preparation procedures of screening, water washing, drying, crushing and mechanical grinding. Material content 0.1%, moisture content 0.5%, Brinell specific surface area 300m 2 / kg, get waste ceramic powder, spare;

[0051] 2) Preparation of pre-ground calcium carbide slag powder: the calcium carbide slag discharged from acetylene production enterprises is prepared by dry method, dried in the sun and ground by vibration mill, and the moisture content of the calcium carbide slag powder after drying and grinding is 0.5%, Brinell specific surface area 320m 2 / kg, its Ca(OH) 2 Content is greater than 70%, f-CaO content is less than 2.5%, SO 3 If the content is less than 2%, the calcium carbide slag powder must be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com