Disc type plucker

A cotton plucking machine and disc-type technology, which is applied in the field of disc-type cotton plucking machines, can solve the problems of low durability and poor impurity removal effect, so as to enhance the durability of use, reduce track vibration, and prevent track deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

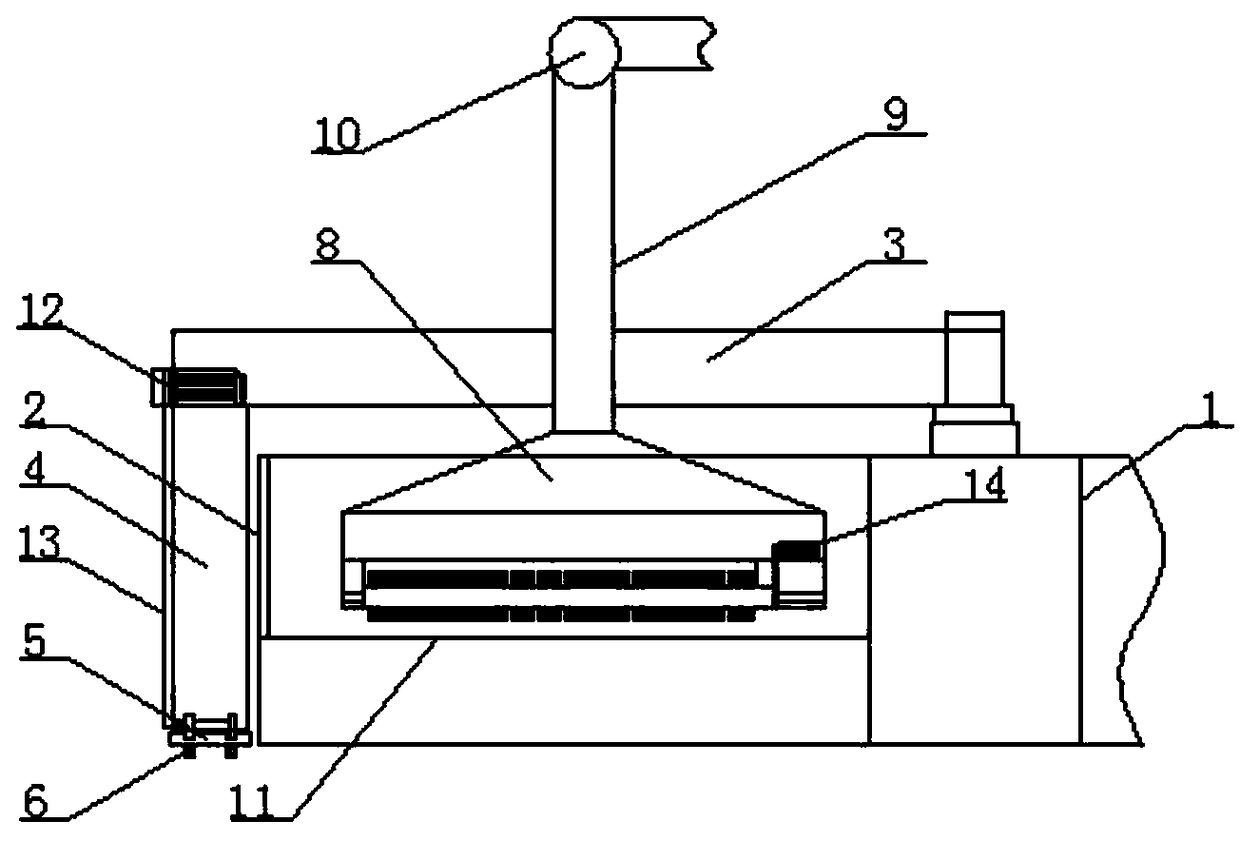

[0031] Such as figure 1 As shown, a disc-type cotton grabbing machine includes: inner wall panel 1, outer wall panel 2, platform 3, rotating trolley 4, track 5, anti-seismic foot 6, beater 7, cotton suction cover 8, cotton suction tube 9. Cotton suction machine10. The outer wall panel 2 is arranged outside the inner wall panel 1, and the outer wall panel 2 and the inner wall panel 1 enclose a circular space 11 for placing cotton. The platform 3 is connected with the inner wall panel 1, the cotton suction cover 8 and the trolley. The trolley is placed outside the outer wall panel 2 and arranged on the track 5 . Driven by the trolley, the platform 3 rotates around the inner wall panel 1, thereby driving the cotton suction cover 8 to move on the cotton placing space 11. The anti-seismic feet 6 are arranged under the track 5 . The cotton suction pipe 9 is connected with the cotton suction cover 8 , and the cotton suction machine 10 is connected with the cotton suction pipe 9 ....

Embodiment 2

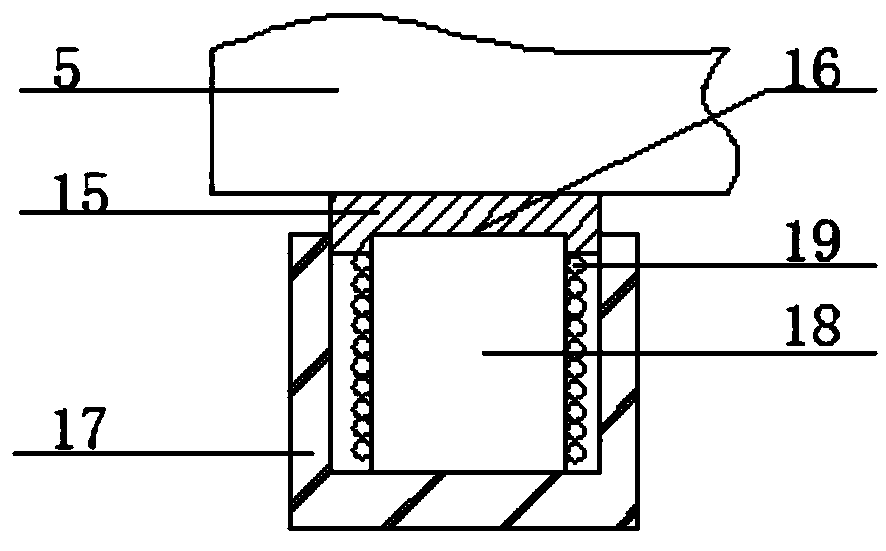

[0035] Such as Figure 4 As shown, a disc-type cotton grabbing machine includes: inner wall panel 1, outer wall panel 2, platform 3, rotating trolley 4, track 5, anti-seismic foot 6, beater 7, cotton suction cover 8, cotton suction tube 9. Cotton suction machine 10; the outer wall panel 2 is arranged outside the inner wall panel 1, and the outer wall panel 2 and the inner wall panel 1 enclose a ring-shaped cotton space 11; the platform 3 is connected to the inner wall panel 1, cotton suction cover 8 and trolley; the trolley is placed outside the outer wall panel 2 and set on the track 5; the anti-seismic foot 6 is set under the track 5; the cotton suction pipe 9 is connected with the cotton suction cover 8, and the suction The cotton machine 10 is connected with the cotton suction pipe 9; the beater 7 is arranged at the lower end of the cotton suction cover 8 and placed in the cotton space 11. Such as Figure 5As shown, since the cotton-absorbing cover 8 vibrates during use,...

Embodiment 3

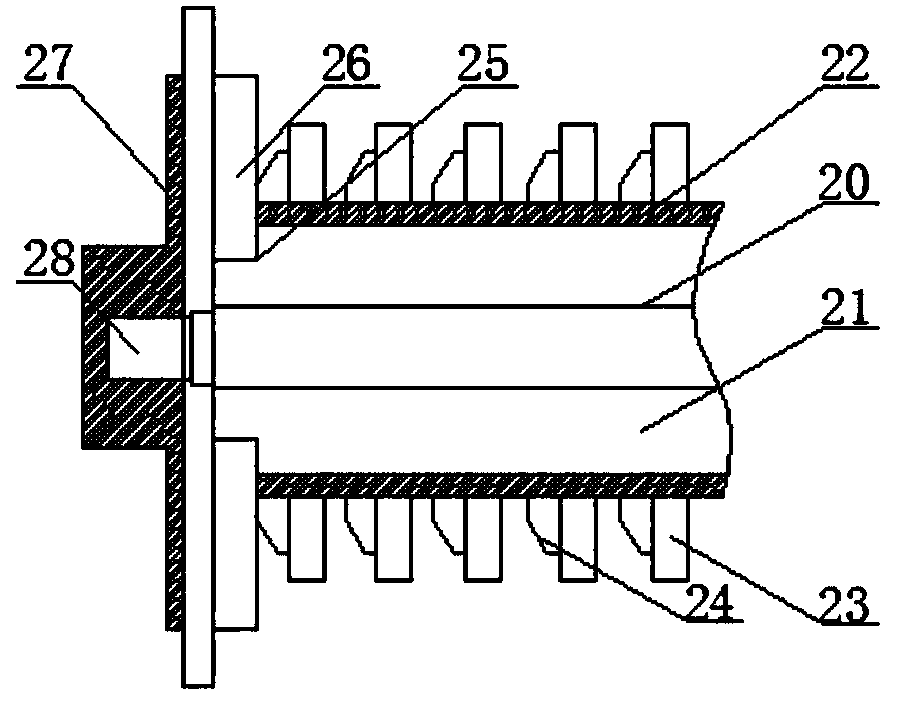

[0038] Such as Figure 8 As shown, a disc-type cotton grabbing machine includes: inner wall panel 1, outer wall panel 2, platform 3, rotating trolley 4, track 5, anti-seismic foot 6, beater 7, cotton suction cover 8, cotton suction tube 9. Cotton suction machine 10; the outer wall panel 2 is arranged outside the inner wall panel 1, and the outer wall panel 2 and the inner wall panel 1 enclose a ring-shaped cotton space 11; the platform 3 is connected to the inner wall panel 1, cotton suction cover 8 and trolley; the trolley is placed outside the outer wall panel 2 and set on the track 5; the anti-seismic foot 6 is set under the track 5; the cotton suction pipe 9 is connected with the cotton suction cover 8, and the suction The cotton machine 10 is connected with the cotton suction pipe 9; the top of the cotton suction cover 8 is connected with a reinforced sleeve 29, and the cotton suction tube 9 is connected with the cotton suction cover 8 through the reinforced sleeve 29; A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com