Lifting control device of gripping arm of reciprocating cotton-grapping machine and control method

A technology of reciprocating cotton grabbing machine and lifting control, which is applied in the program control, electrical program control, fiber opening and cleaning machine in the sequence/logic controller, etc. The gears of the reduction box are damaged, and it is difficult to reach the lifting position, so as to improve the lifting positioning accuracy, reduce the impact and interference, and reduce the failure rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with specific embodiment the present invention is described in further detail:

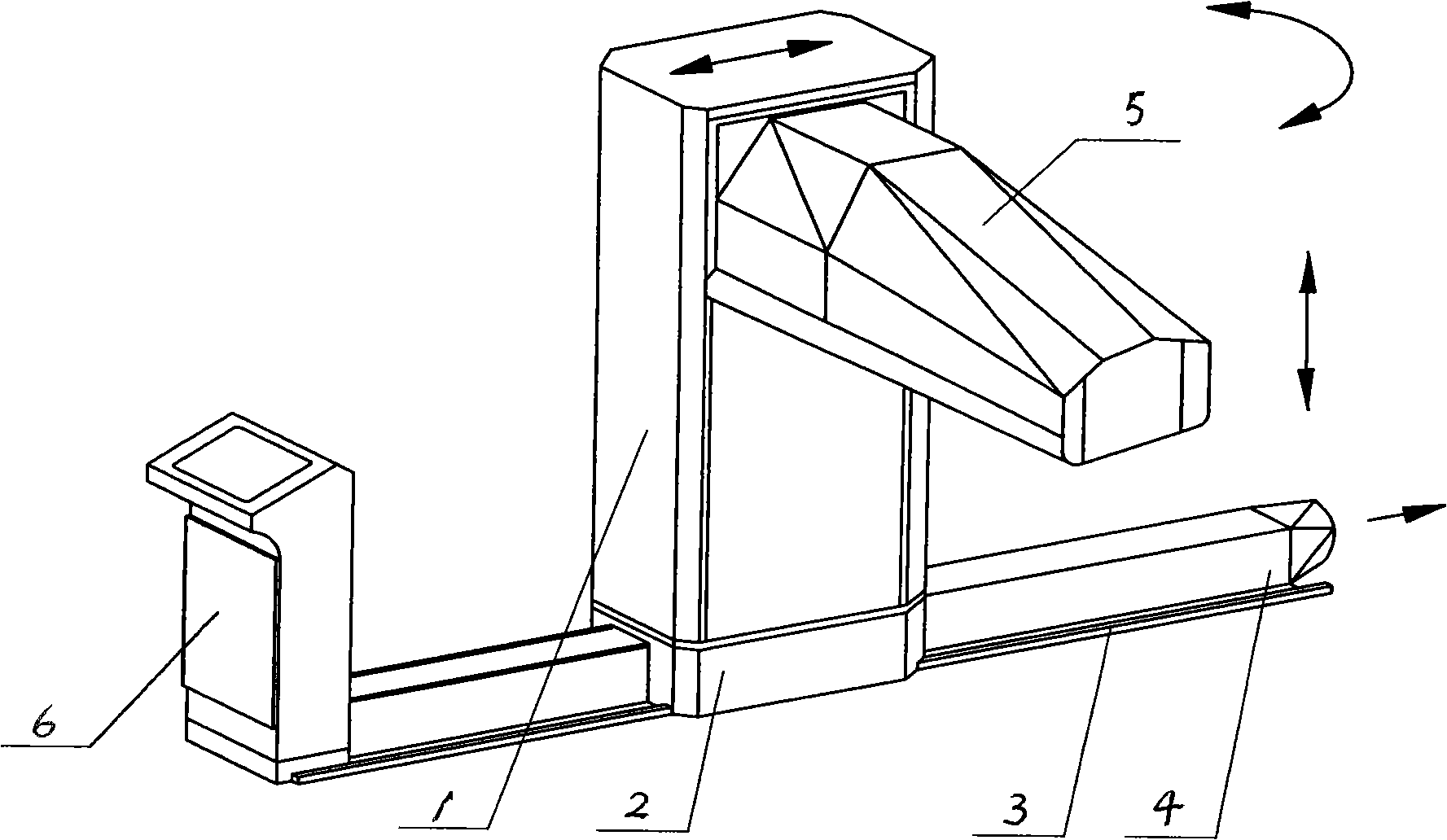

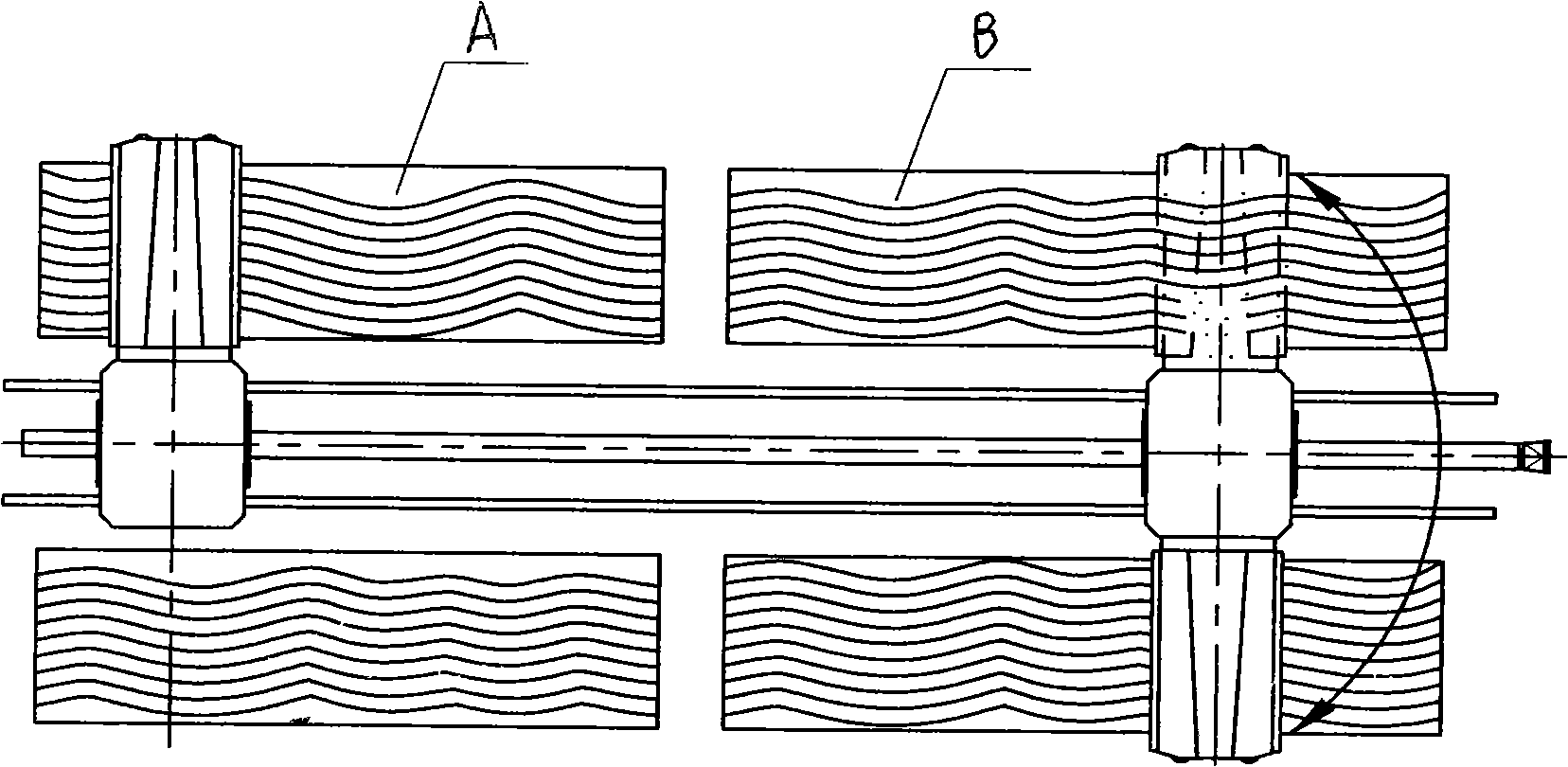

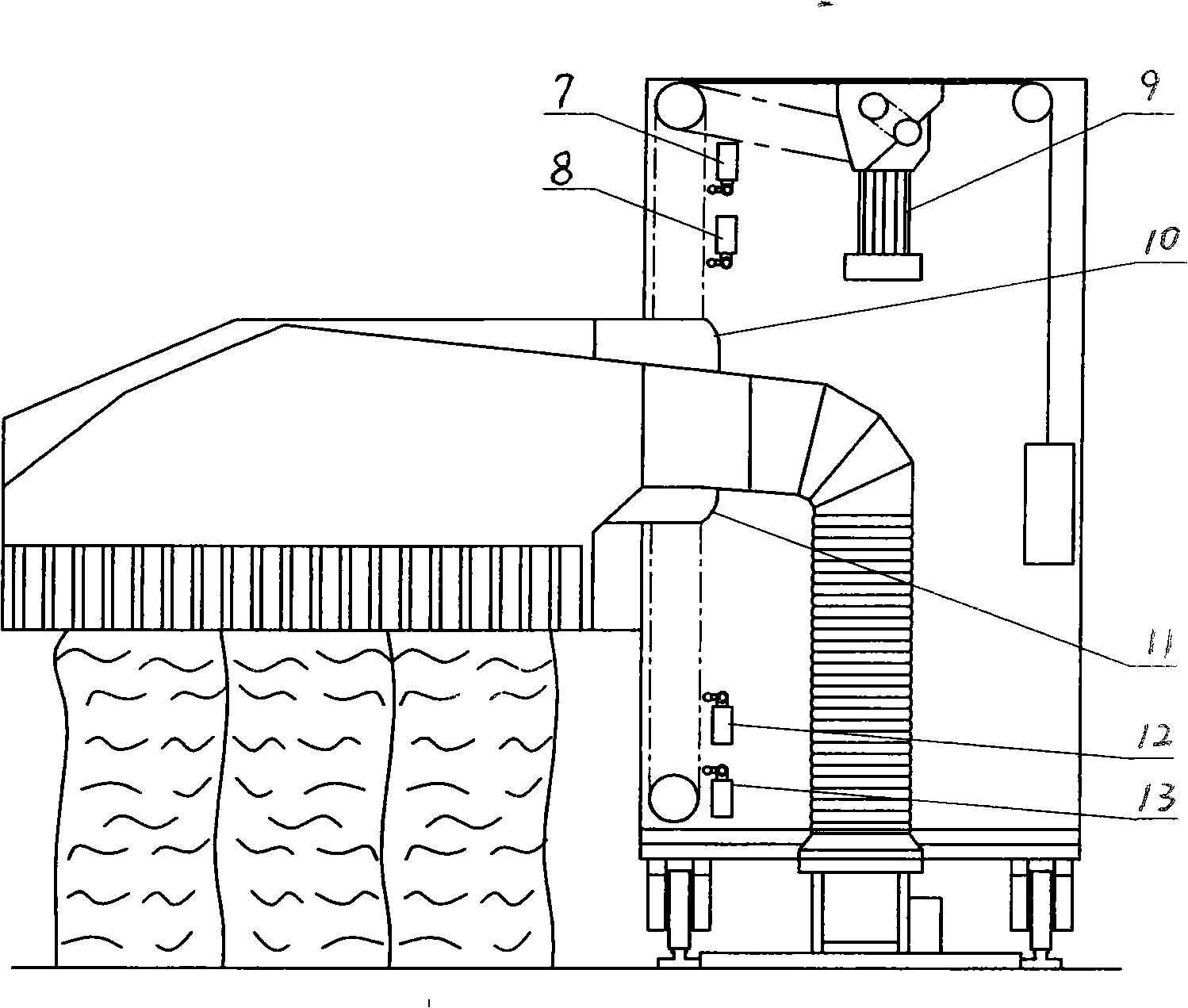

[0022] see Figure 1-Figure 3 , an embodiment of the lifting control device for the grasping arm of a reciprocating plucker according to the present invention, including a tower base 2, a tower body 1, a grasping arm 5, a suction groove 4, a guide rail 3, a tower drive motor 9, a grasping arm lifting motor and control In the control cabinet 6 of the system, the lifting motor 9 is equipped with a frequency conversion controller or an integrated frequency conversion machine. A sensor that detects the lifting position of the grab arm is installed on the output shaft of the lifting motor 9; the sensor is connected with the computer of the control cabinet, and the output of the computer is connected with the frequency conversion controller of the lifting motor. The sensor sends detection data into the computer of the control system, and the computer outputs instructions to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com