Suction cowl device of plucker

A cotton grabbing machine and cotton grabbing beater technology, which is applied in the field of cotton spinning machinery, can solve the problems of reduced service life of equipment, insufficient concentration of suction force, blockage of suction hoods and cotton conveying pipelines, etc., to prevent blockage and damage, improve efficiency, and improve suction Cotton efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

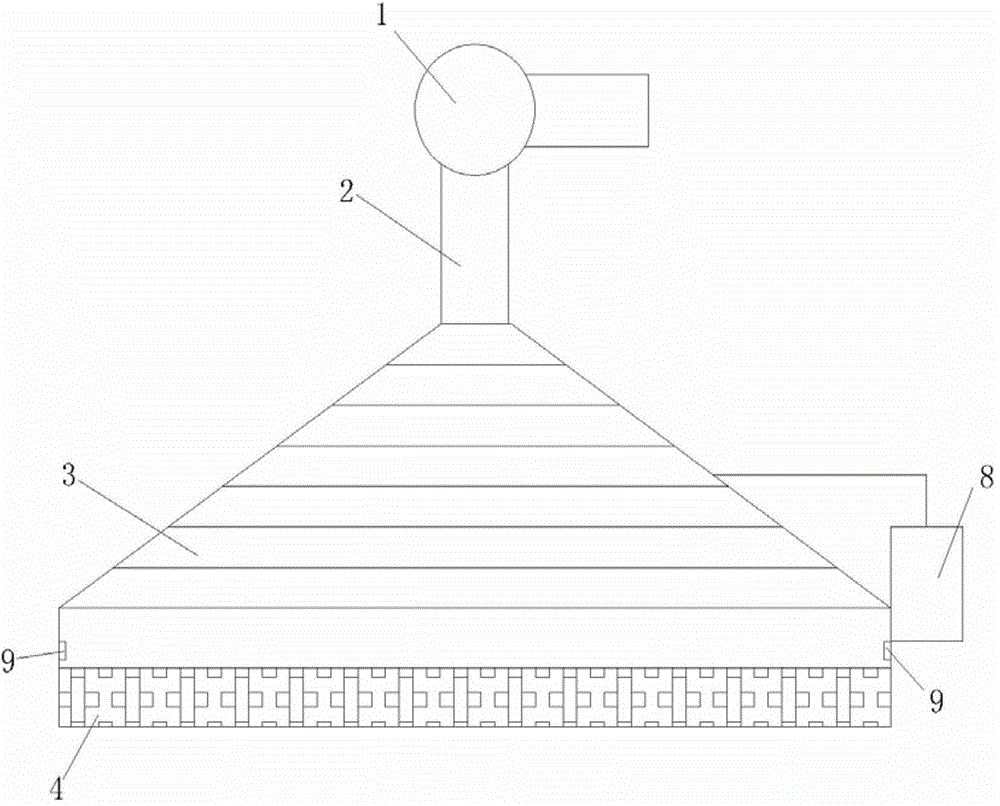

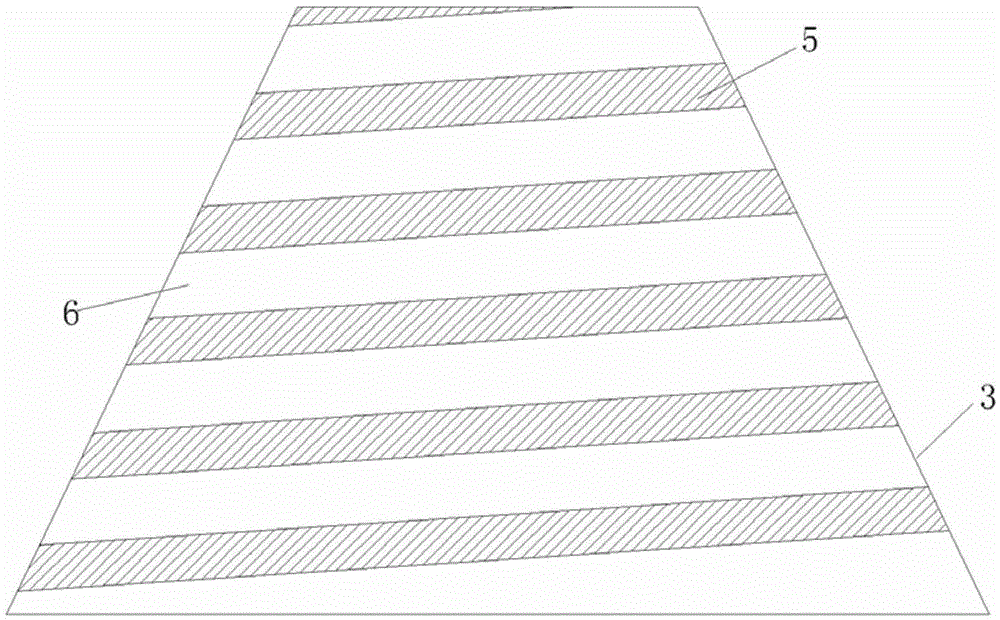

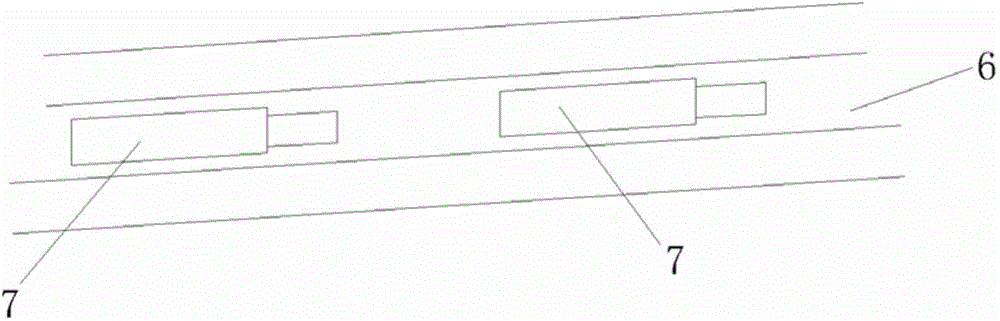

[0018] see figure 1 , figure 2 and image 3 , the suction hood device of the cotton catching machine described in the present invention, comprises blower fan 1, cotton conveying pipe 2, suction cover 3, catches cotton beater 4; On the inner wall of described suction hood 3, a plurality of spirally arranged air guide strips 5 are formed , there is a groove 6 between the two adjacent air guiding strips 5, and an electromagnet 7 is arranged on the groove 6, and the electromagnet 7 is connected with the controller 8; on the inner wall of the suction cover 3 A photoelectric sensor 9 is provided. In this embodiment, two photoelectric sensors 9 are respectively arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com