Annular bale plucker

A cotton plucking machine and ring-shaped technology, which is applied in the field of ring-shaped cotton plucking machines, can solve problems such as poor water spray uniformity, difficult humidity control, unfavorable production, etc., and achieve the effects of large coverage, uniform humidification, and good dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

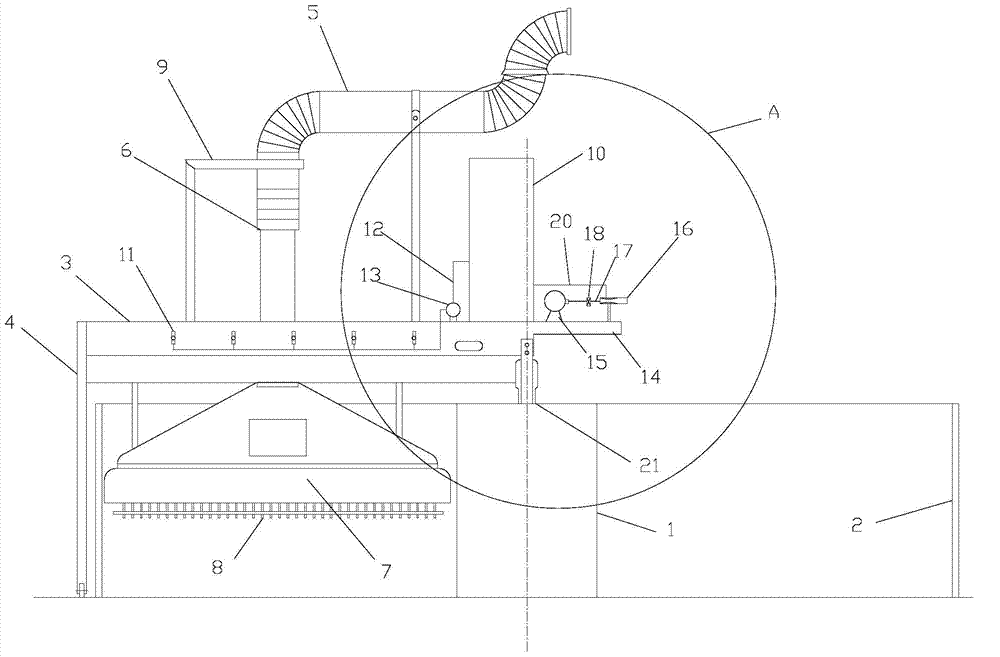

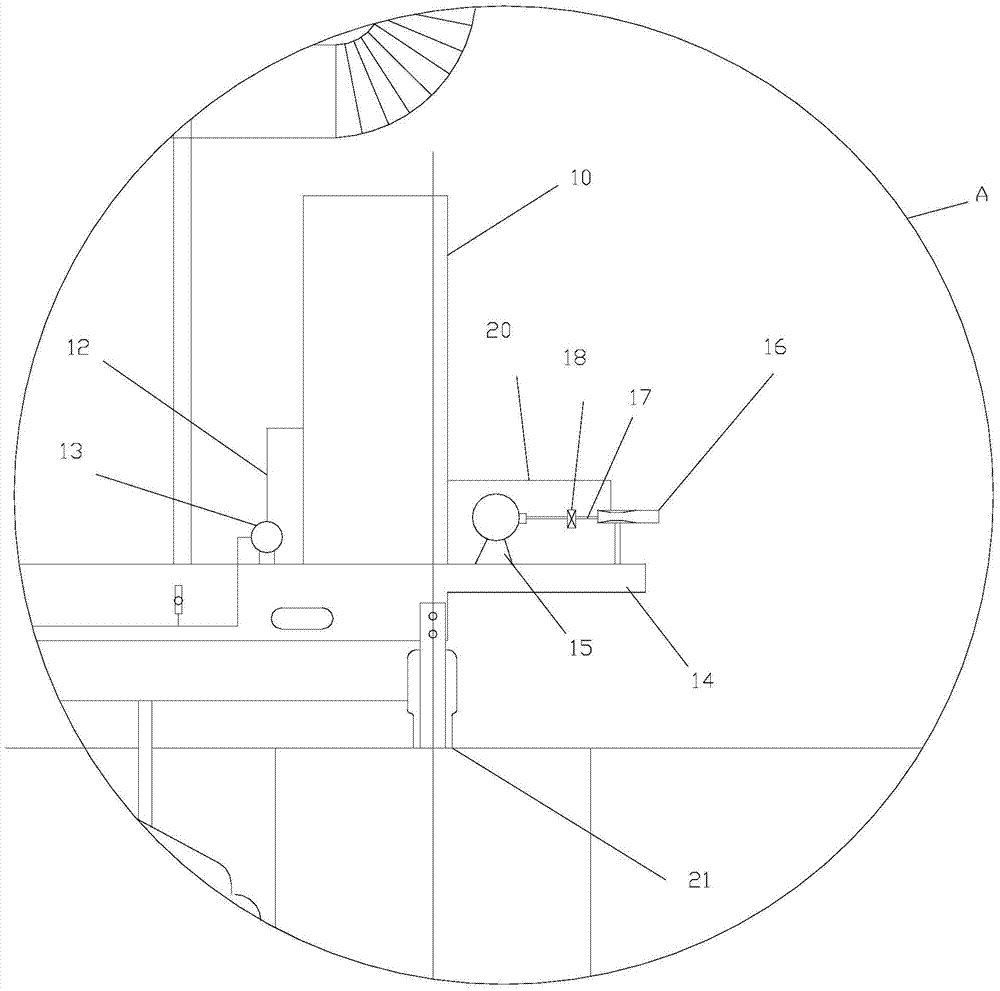

[0021] Such as figure 1 , 2 As shown, a ring-shaped cotton grabbing machine described in this embodiment includes an inner ring wall panel 1, an outer ring wall panel 2, a platform 3, a trolley 4, a cotton delivery tube 5, a telescopic tube 6, a cotton suction cover 7, a beater 8 and bracket 9, the inner ring wall panel 1 and the outer ring wall panel 2 are distributed concentrically; one end of the platform 3 is connected to the inner ring wall panel 1 through a slip ring mechanism 21, and the other end is connected to the top of the trolley 4, and the trolley 4 Located on the outer side of the outer wall panel 2, the telescopic tube 6 passes through the platform 3, the top of the telescopic tube 6 is connected to the cotton delivery tube 5, and the bottom is connected to the cotton suction cover 7, the beater 8 is located at the bottom of the cotton suction cover 7, and the bracket 9 is located on the platform 3 It is used to fix the telescopic tube 6, and the platform 3 is...

Embodiment 2

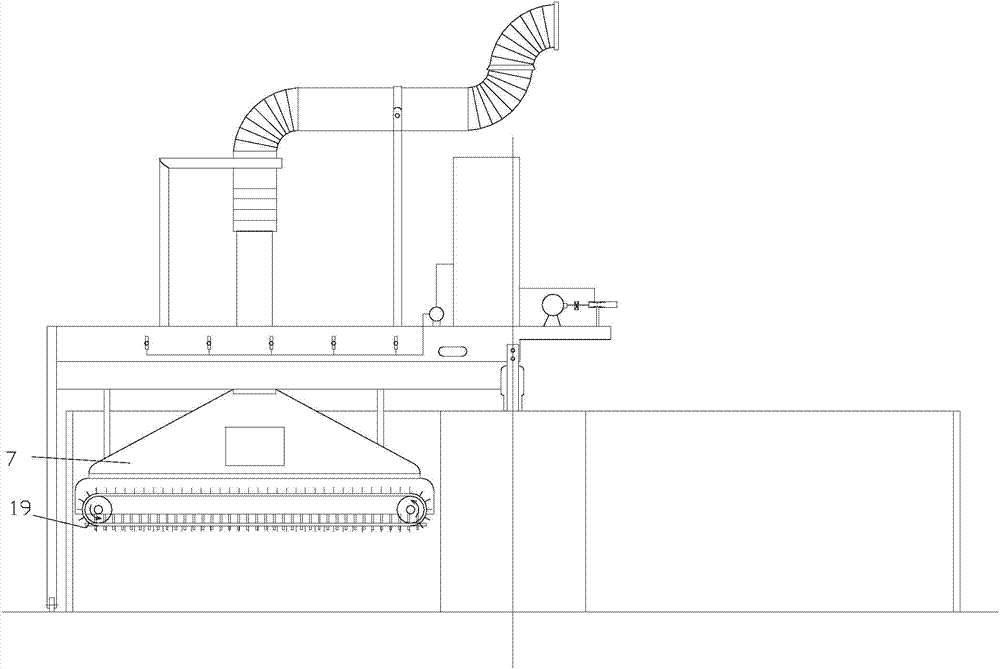

[0026] Such as image 3 As shown, the ring-shaped cotton grabbing machine described in this embodiment is different from Embodiment 1 in that: the rear side wall of the cotton suction cover 7 is provided with an electric conveyor belt 19 . Motorized conveyor belts 19 are used in the initial stages of production.

[0027] When feeding, the operator generally puts the cotton block near the outer ring wall panel 2. On the one hand, because the operator’s hand is not long enough, on the other hand, for the sake of labor saving, when the cotton plucker is just running, the cotton The layer is usually very full and forms a shape that is high on the outside and low on the inside. When the plucking machine rotates, the cotton layer overflows the outer ring wallboard 2 easily. In the production process, the cotton layer has a process of moving to the inner side, which can prevent the cotton layer from overflowing the outer ring wallboard 2, and when the cotton layer height is low, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com