Untwisting drawing device

A drafting device and untwisting technology, applied in the field of yarn untwisting drafting device, can solve the problems of high hairiness, difficulty in achieving uniform and smooth yarn, poor efficiency and effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

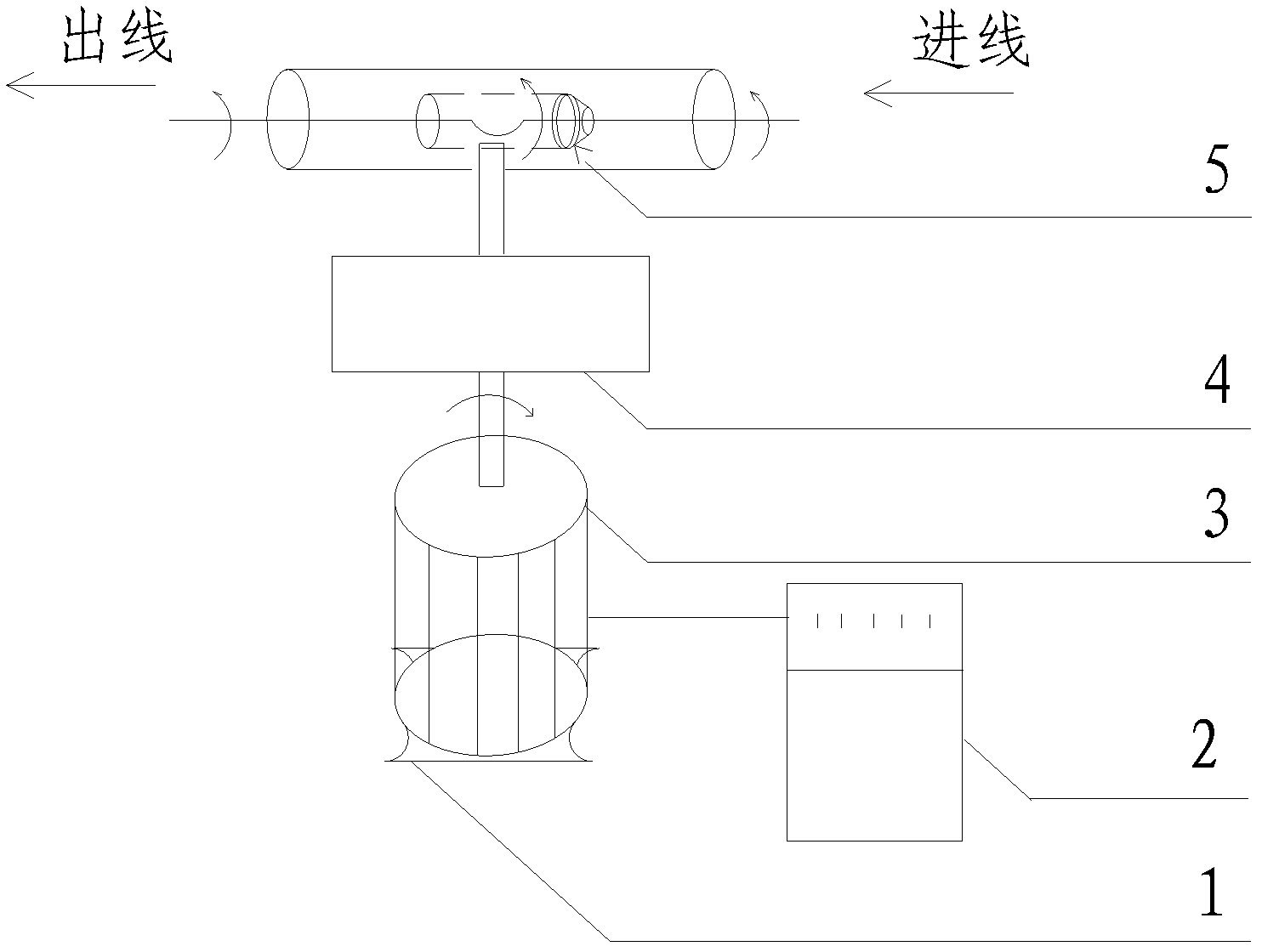

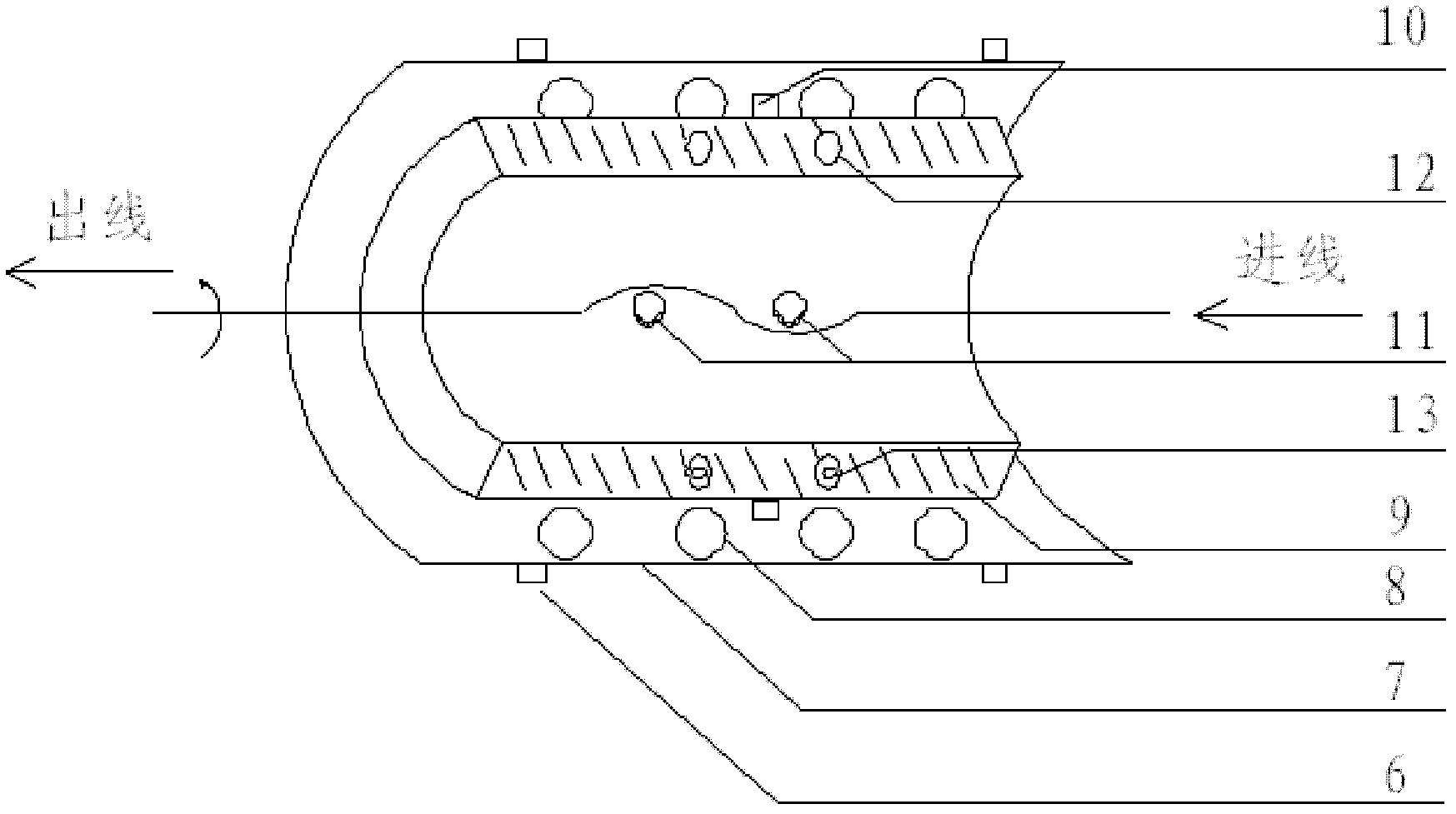

[0020] as attached figure 1 , 2 As shown, a kind of untwisting drafting device comprises miniature high-speed motor 2, speed control and display system 3, rotation direction converter 4, untwisting drafting device 5, and described miniature high-speed motor 2 is connected with speed control and display System 3, the miniature high-speed motor 2 is also connected with the untwisting drafter 5 through the rotation direction converter 4, and the untwisting drafter 5 includes a fixed cylinder 7, a ball 8, a roller 9, a roller shifting tooth 10, The dial 11, the inside of the fixed cylinder 7 is connected to form a whole by the ball 8 and the roller 9, there are a plurality of roller dial teeth 10 on the roller 9, and a plurality of dials 11 are arranged in the middle of the roller 9. The untwisting drafter 5 is composed of two semicircular structures, the two sides of the semicircular structure of the roller 9 have corresponding pins 13 and jacks 12 respectively, and the outer si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com