Wool and true silk blended knitted fabric

A technology of knitted fabrics and real silk, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve the problems of being difficult to make thin, thick fabrics, easy to fluff and pilling, etc., to reduce the thickness of fabrics and improve support. Number, good effect of warmth retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

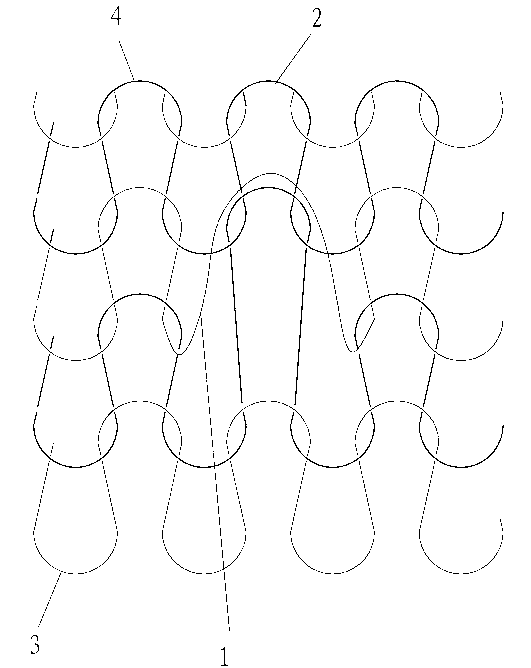

[0018] A wool and silk blended knitted fabric, which is composed of wool yarn 4 and silk yarn 3 mixed to form a plurality of closed loops 2, and an unclosed hanging loop 1 is arranged on the loop 2, and the number of stitches of each hanging loop 1 is Both are one stitch, and the hanging arc 1 draws the coil 2 into an elongated coil; the woolen yarn 4 and the silk yarn 3 are arranged horizontally to form horizontal stripes; the weight ratio of the woolen yarn 4 and the silk yarn 3 is 7:1; Among them, the wool yarn 4 is mercerized wool with a count of 60s, and the count of the silk yarn 3 is 60s; after the finished product, the density PA of the wool yarn 4 and the silk yarn 3 is 60 columns / 5CM, and the PB is 55 rows / 5CM .

[0019] After the weaving of the fabric, the polyether modified amino silicone oil finishing agent is used for dipping and finishing to make the semi-finished fabric, which makes the fabric more hydrophilic, soft, and easier to decontaminate, improving the c...

Embodiment 2

[0022] The difference from Example 1 is that the wool yarn 4 is mercerized wool with a count of 65s, and the count of the silk yarn 3 is 65s; the density PA of the wool yarn 4 and the silk yarn 3 after the finished product is 65 tandem / 5CM, PB is 60 rows / 5CM.

Embodiment 3

[0024] The difference from Example 1 is that the wool yarn 4 is mercerized wool with a count of 70s, and the count of the silk yarn 3 is 70s; the density PA of the wool yarn 4 and the silk yarn 3 after the finished product is 70 tandem / 5CM, PB is 65 rows / 5CM.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com