Synthetic turf

A technology of turf and composite yarn, which is applied in textiles, sports accessories, yarns, etc. It can solve the problems of synthetic turf forming visible patterns after using it, and achieve the effect of easy recycling, not easy to burn, and soft touch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

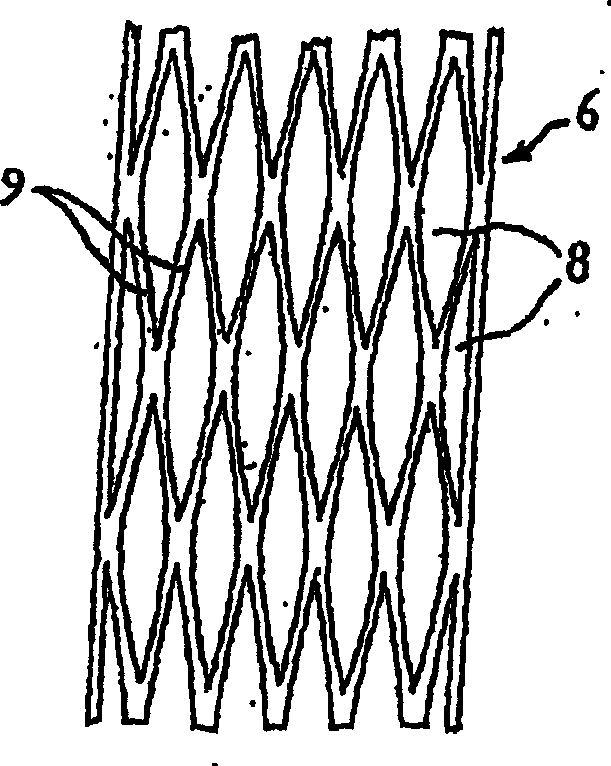

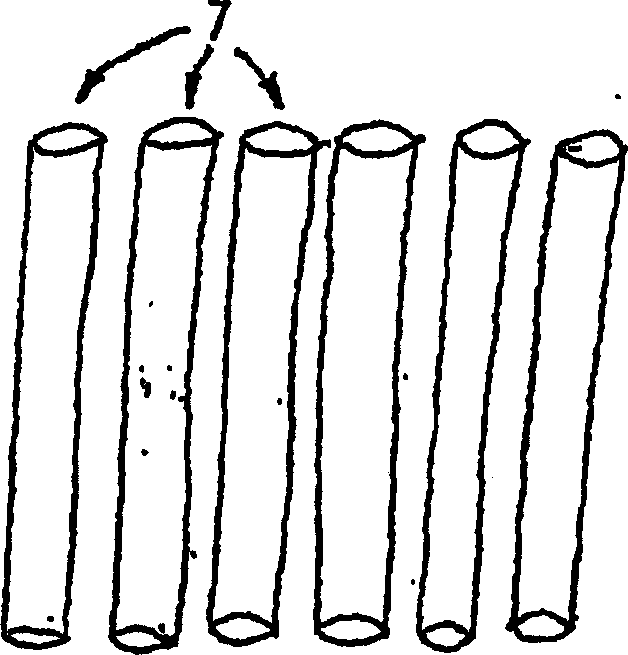

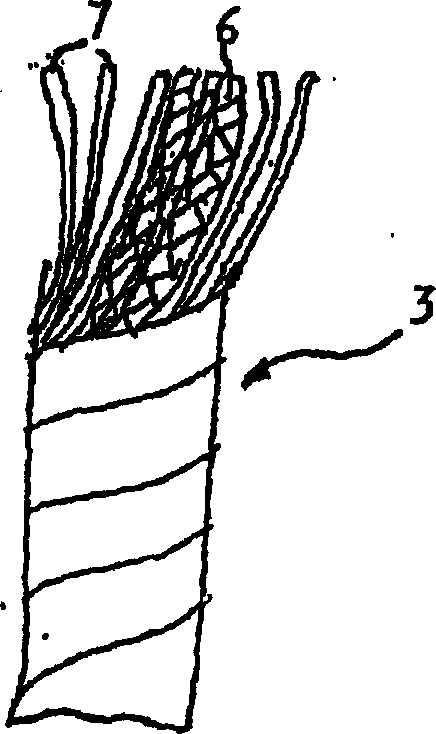

[0059] The composite yarn 3 is first prepared by twisting a fibrillated yarn 6 around six monofilament yarns 7 . The fibrillated yarn had a yarn count of 6600 denex and a thickness of 80 μm. The spacing d between the slits is such that the filament width varies, more specifically between about 0.1 and 1.2 mm. Each monofilament yarn has a yarn count of 1400 denex, a thickness of 160 μm, and a width of 1.4 mm. The yarn count of the composite yarn was 15000 denex. The different yarns are all prepared from polyethylene with UV and heat stabilizers and green pigments. The composite yarns are tufted on a backing layer consisting of a woven polypropylene layer and a fiberglass mesh. The gauge of the tufting machine was set at 5 / 8". The average height h of the tufts was about 5 cm. A latex adhesive was applied to the back of the backing layer to hold the tufts in place. The resulting synthetic grass is shown in Figure 4 . In the cross-sectional view of this figure, only a portio...

Embodiment 2

[0061] Composite yarns are prepared by twisting two monofilament yarns around four monofilament yarns. The single tape yarn has a yarn count of 2200 denex and a thickness of 100 μm. The width of the single tape yarn is 2.5mm. The monofilament yarn has a yarn count of 1400 denex and a thickness of 160 μm. The monofilament width is 1.4mm. The yarn count of the composite yarn was 10,000 denex. The composite yarns are tufted on a backing layer consisting of a woven polypropylene layer and a fiberglass mesh. A latex adhesive is applied to the back of the backing layer to hold the tufts in place. This synthetic turf directly resembles natural grass, meaning that no post-fibrillation or abrasion process is required to achieve this appearance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com