Variable path automated guided vehicle

An automatic guidance, vehicle technology, applied in navigation, mapping and navigation, instruments, etc., can solve problems such as floor abrasion, difficulty, misleading AGV guidance path, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention relates to an apparatus and method for guiding an automated guided vehicle (AGV) along a variable path of travel to reduce wear patterns in the floor of a material handling facility.

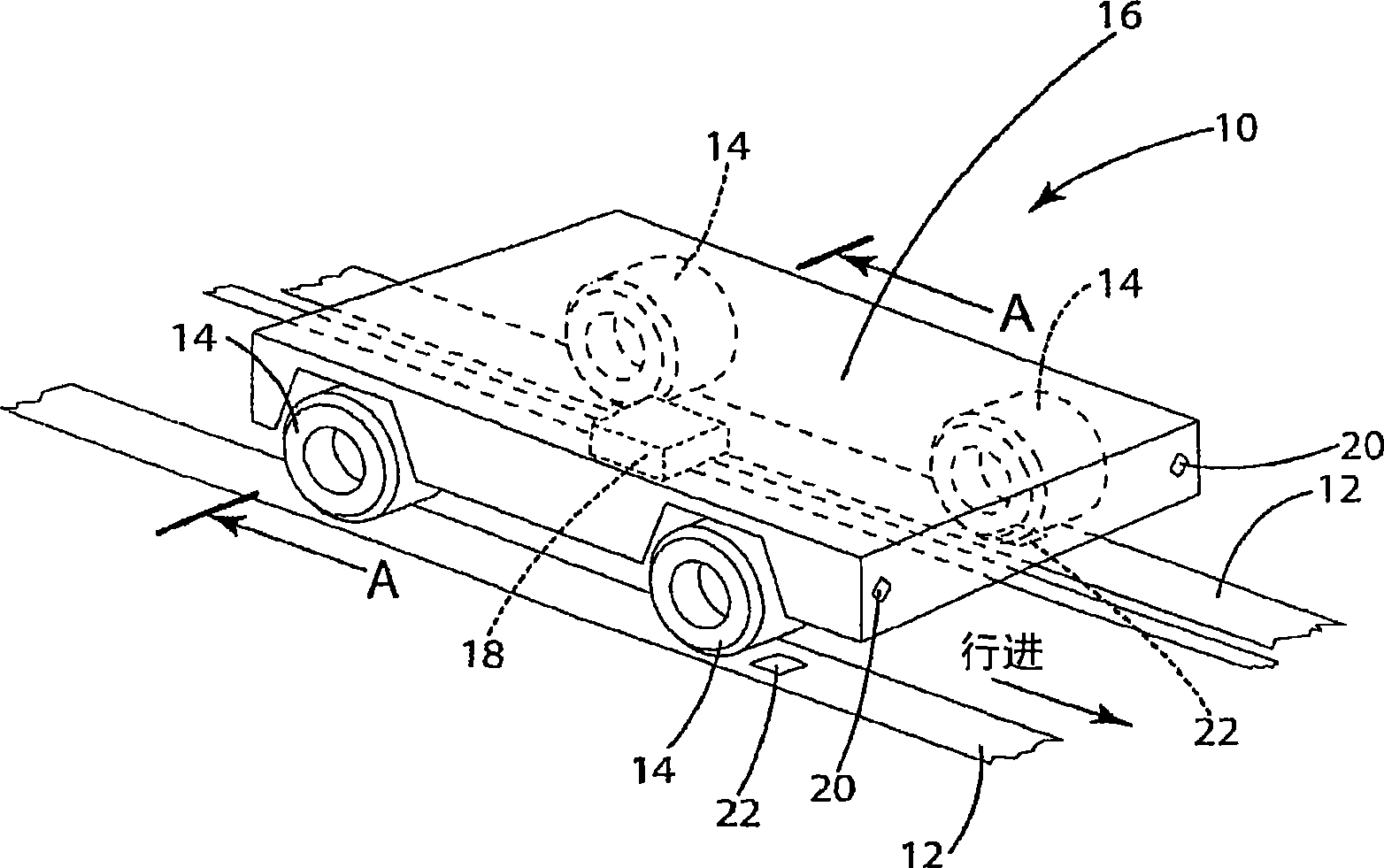

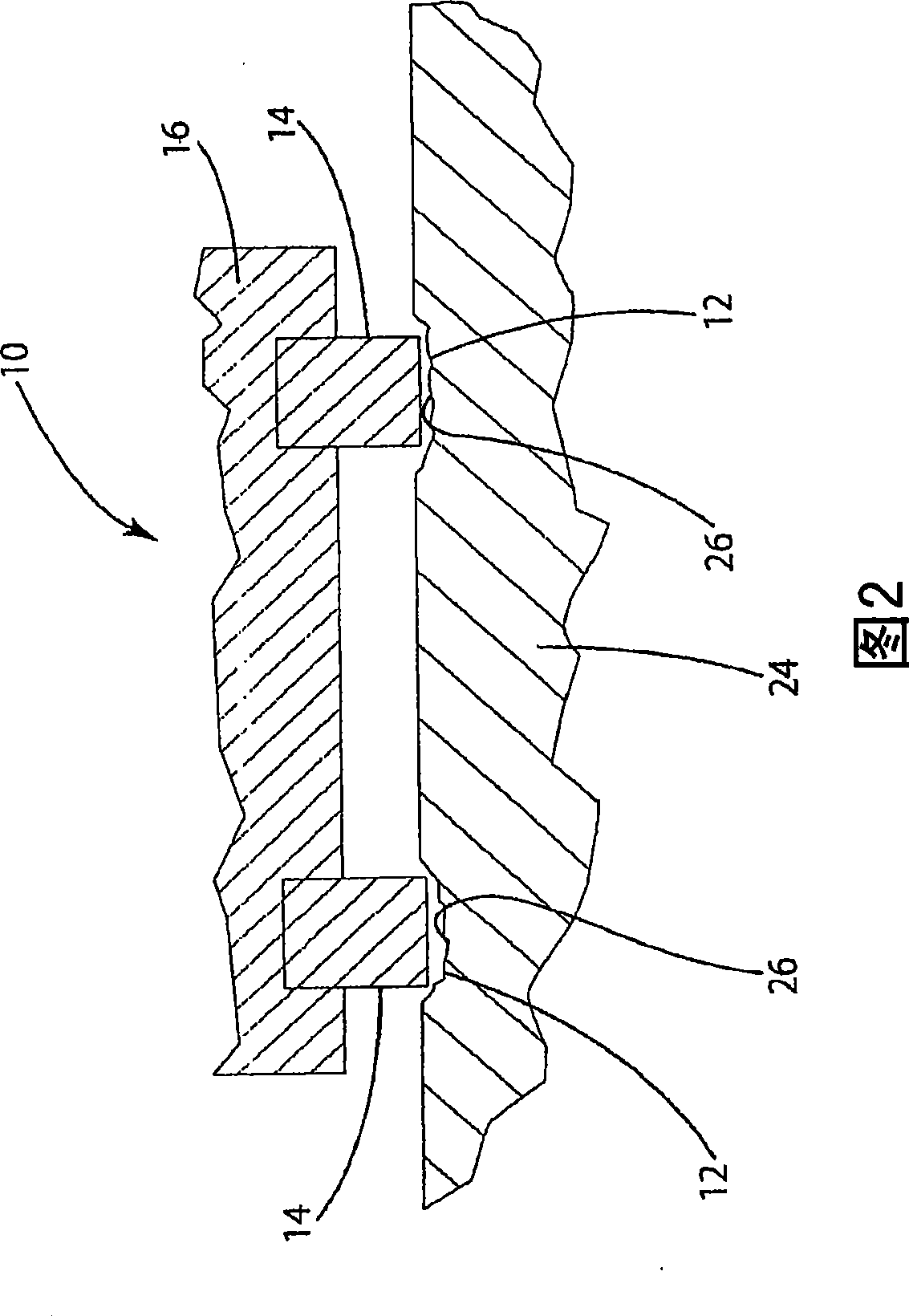

[0022] exist figure 1 An AGV traveling along a predetermined route 12 in the floor of a materials handling facility is indicated generally at 10 in the drawings. In this example, the AGV 10 includes wheels 14 for traveling along a predetermined route 12 and a frame 16 for housing a load (not shown). It should be understood that the present invention is not limited to AGVs having four wheels, but may also include various other wheel configurations, including, for example, three wheel configurations with one drive wheel and one steer wheel. The frame 16 of the AGV 10 includes a controller 18 which is used in conjunction with the detection system. The frame 16 may incorporate many different features and is not meant to be limited to a flat bed, for example the frame 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com