High-cold wind-sand environment wheel rail abrasion simulation experimental device

A technology for simulating experimental equipment and wind and sand, applied in the direction of testing wear resistance, etc., can solve problems such as long time consumption, complex wheel and rail wear mechanism, difficult theoretical simulation, etc., and achieve the effect of facilitating heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

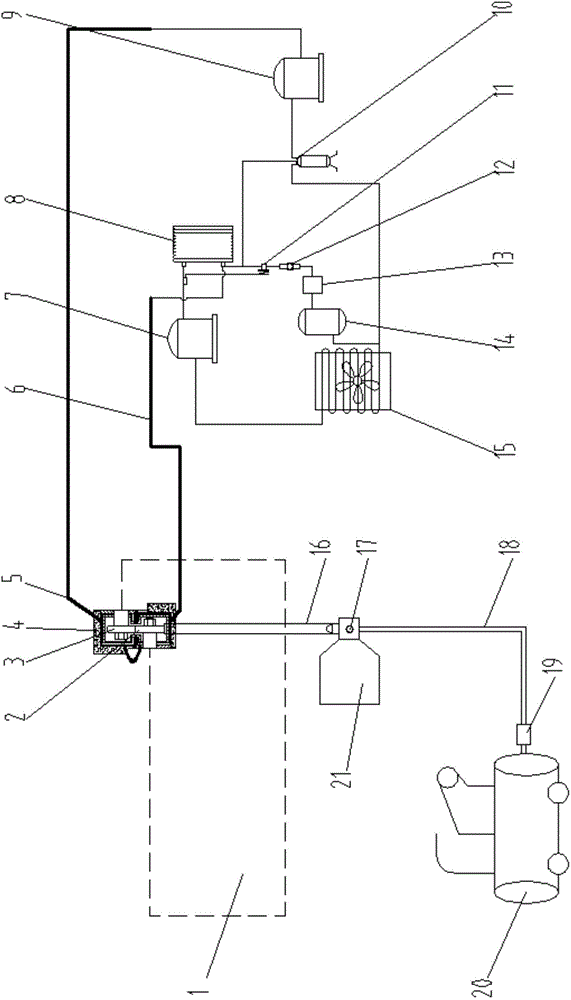

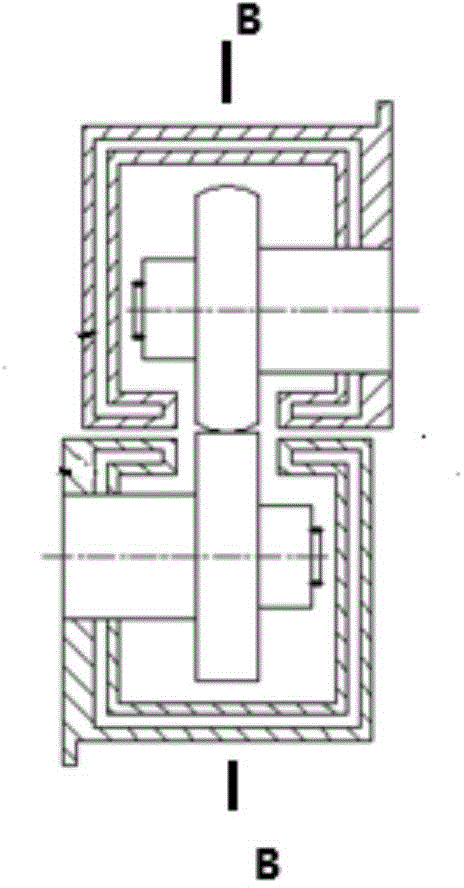

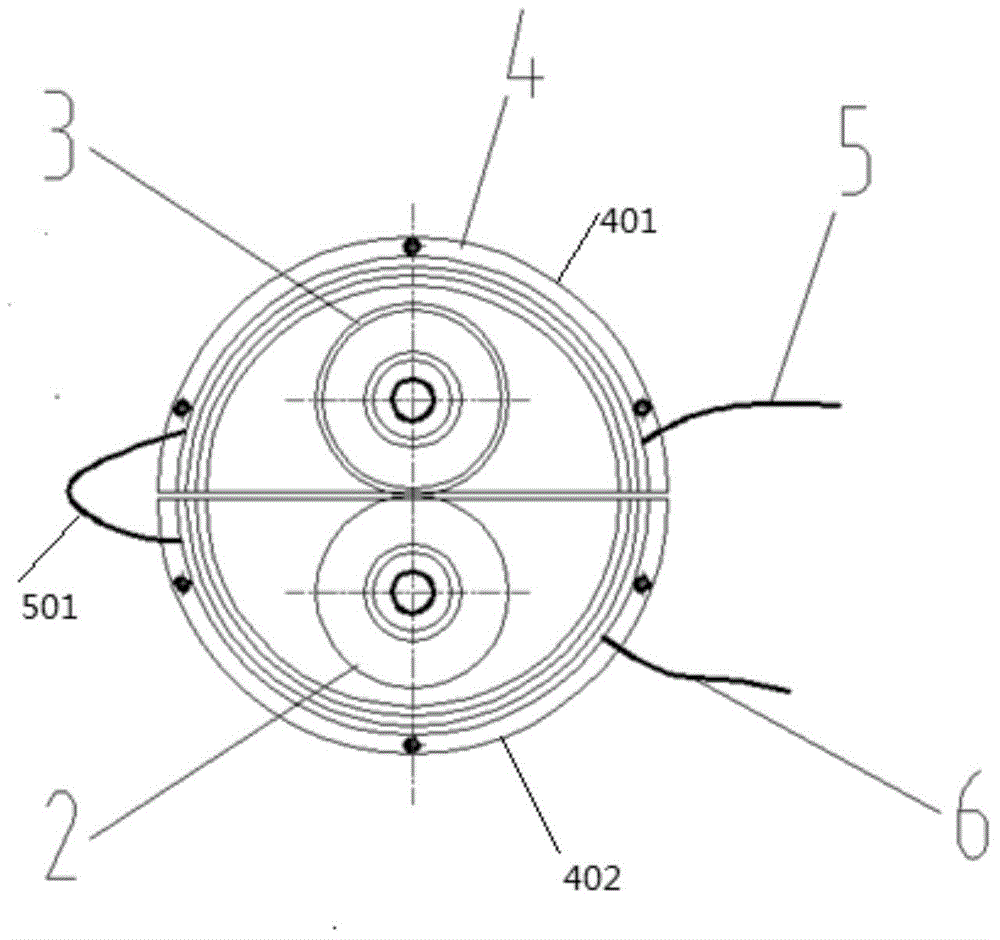

[0027] Figure 1-3 Shown, a kind of specific embodiment of the present invention is:

[0028] The wheel-rail wear simulation experiment device in the alpine wind and sand environment is composed of:

[0029] 1 is WR-1 wheel-rail rolling wear testing machine, the low-temperature sandstorm environment chamber 8 is covered on the wheel-rail rolling wear platform of the test machine, and the low-temperature sandstorm environment chamber 8 communicates with the sandstorm simulation control unit through the sand delivery pipe 16; The composition of the analog control unit is as follows: the air compressor 20 is connected to one mouth of the air outlet pipe 18 through the wind speed regulating valve 19, and at the same time at the sand supply container 17, the other mouth of the air outlet pipe 18 is successively connected with the sand amount regulating valve 17 and One nozzle of the sand sending pipe 16 is connected, and the other nozzle of the sand sending pipe 16 is aligned with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com