Continuously variable steering mechanism for tracked vehicle

A technology of continuously variable speed change and steering mechanism, which is applied to tracked vehicles, steering mechanisms, non-deflectable wheel steering, etc., can solve the problems of high risk factor, rollover accidents, and low turning accuracy, and achieve stable transmission performance, simple structure, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

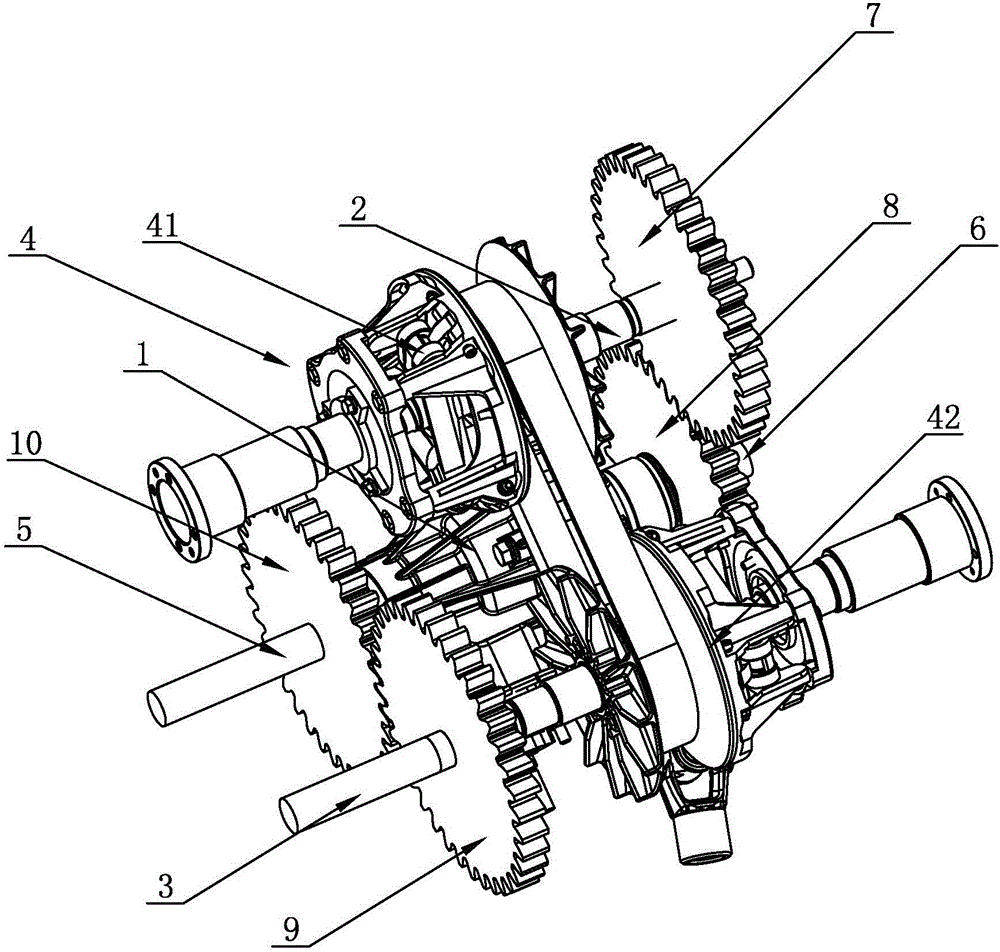

[0011] like figure 1 As shown, a continuously variable steering mechanism of a tracked vehicle includes a differential 1, a right transmission shaft 2, a left transmission shaft 3, and a continuously variable transmission 4 for adjusting the rotational speeds of the right transmission shaft 2 and the left transmission shaft 3, A left half shaft 5 and a right half shaft 6 are connected to the differential 1, a first right transmission gear 7 is set on the right transmission shaft 2, and a second right transmission gear is set on the right half shaft 6 of the differential 1 8. The first right transmission gear 7 meshes with the second right transmission gear 8 to form the linkage cooperation between the right half shaft 6 of the differential 1 and the right transmission shaft 2, and the left transmission shaft 3 is sleeved with the first left transmission gear 9, The left half shaft 5 of the differential 1 is sleeved with a second left transmission gear 10, and the first left tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com