Drive device for the spindles of a ring spinning machine

A technology of ring spinning machine and driving device, applied in spinning machine, continuous winding spinning machine, textile and papermaking, etc., can solve the problem of synchronous operation of tangential transmission belt without mentioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

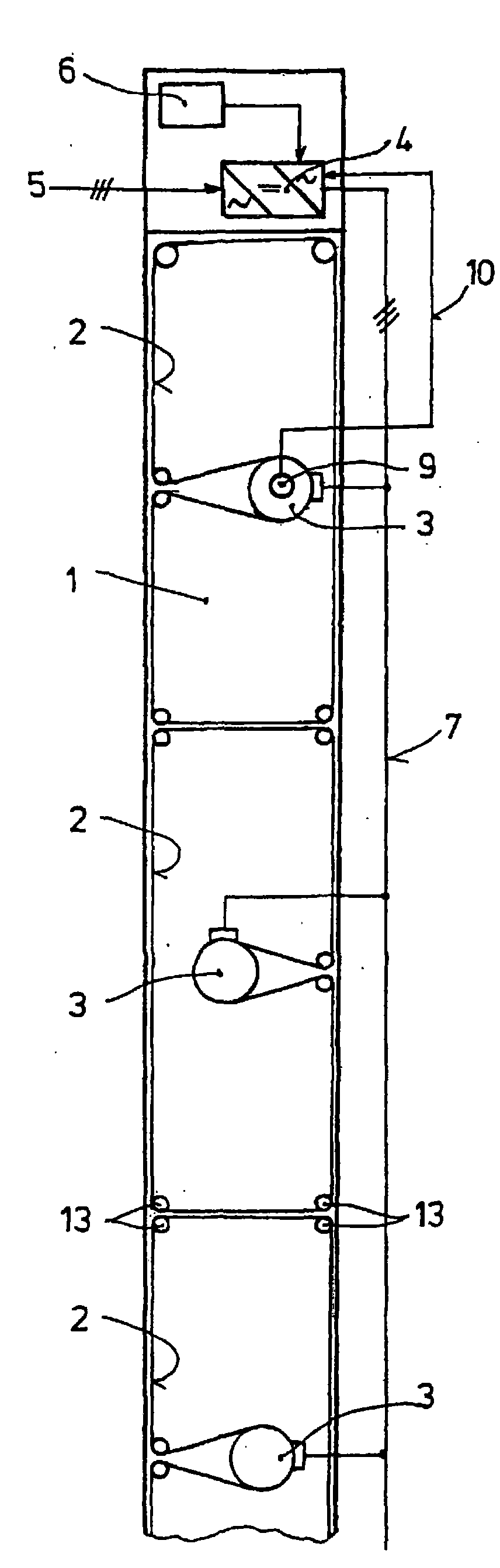

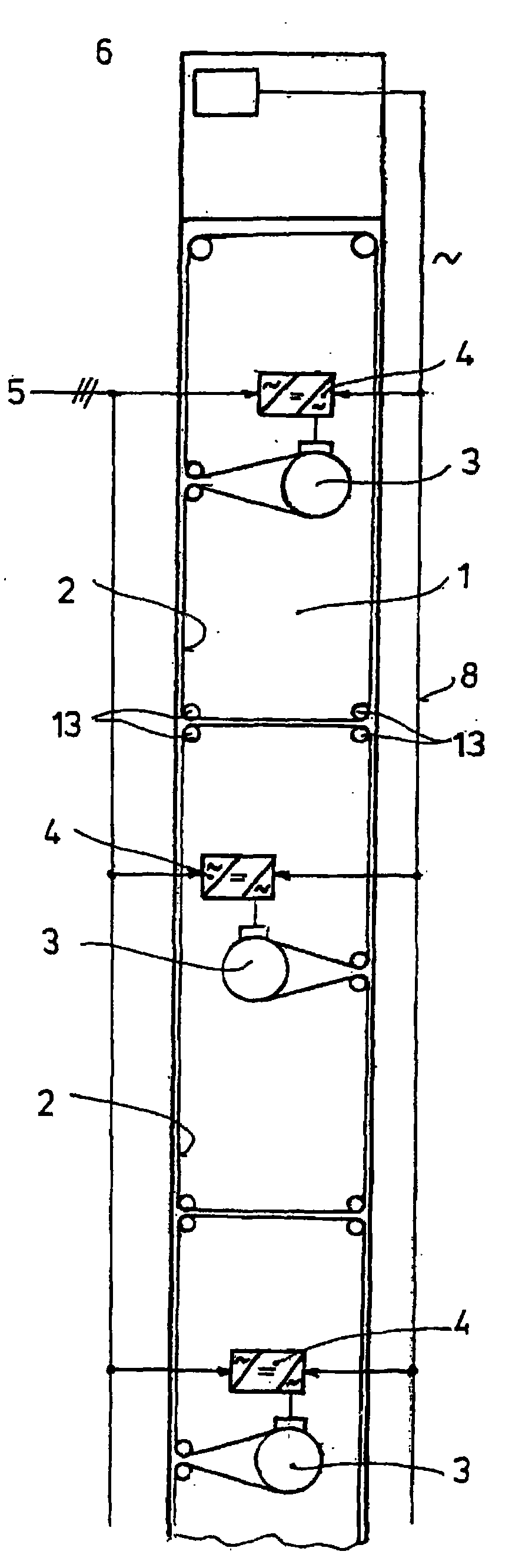

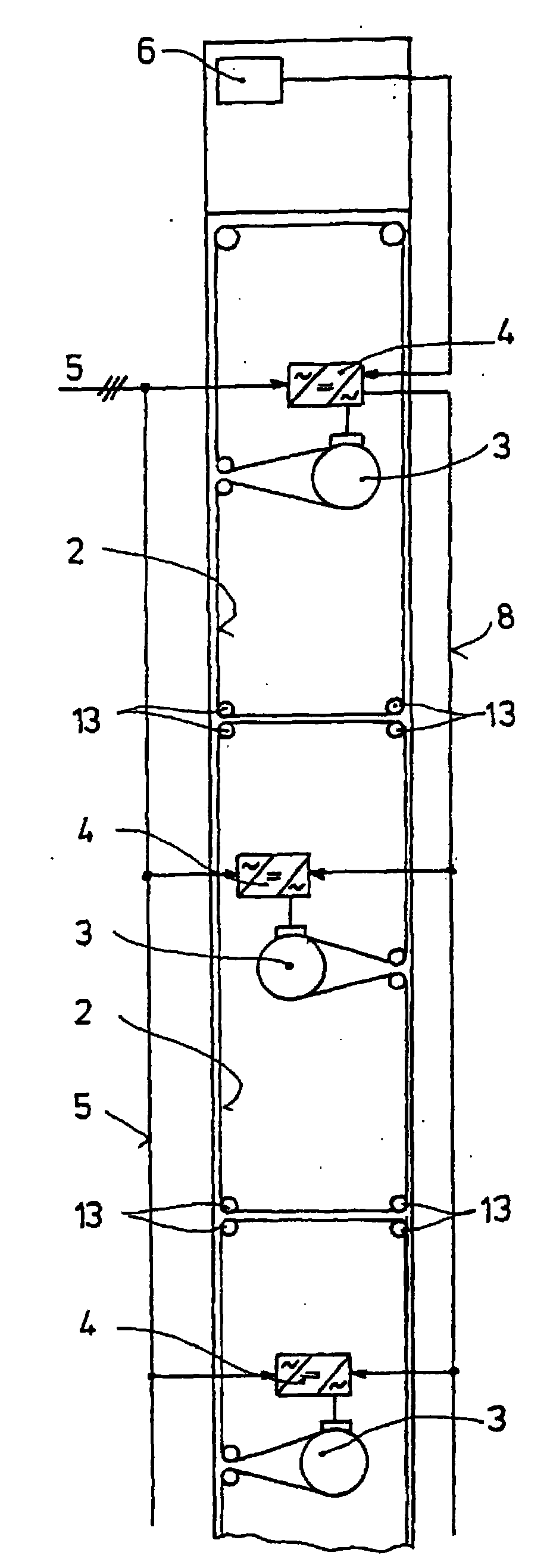

[0029] figure 1 A plan view of a ring spinning machine 1 is shown, which has a plurality of spindles (not shown here) on both longitudinal sides, which are driven in sections by means of tangential drive belts 2 . Each tangential belt drives a plurality of spindles on both sides of the machine, while each tangential belt itself is driven by means of an electric motor 3 . These electric motors are designed as synchronous motors. The feed current for these electric motors is generated by a frequency converter 4 which, via an intermediate DC circuit, generates alternating (polyphase) electricity of a certain frequency (the frequency of which is preferably variable) from the frequency of the grid 5 . The control of this feed frequency takes place in the form of the spindle speed which is predetermined by the machine controller 6 via an interface for the frequency converter 4 . Specifically, the acceleration of the spindle when it is started and the reduction of the rotational sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com