Mower

A lawnmower and grass-cutting technology, which is applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of wasting energy, damaging the mowing device, and large resistance, so as to avoid energy waste and avoid energy loss. Waste, the effect of increasing the input current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

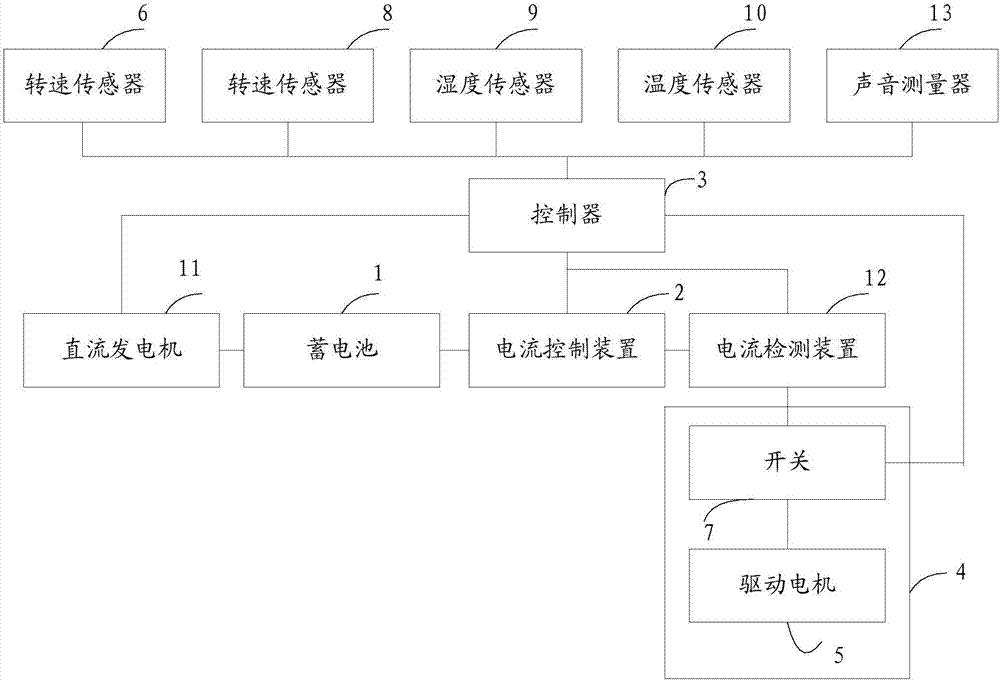

[0042] Please refer to figure 1 , Embodiment 1 of the present invention is:

[0043] A lawnmower provided by the present invention includes a DC generator, a storage battery, a current control device, a controller, a lawn mowing device, a current detection device and a sound measuring device;

[0044] The DC generator is electrically connected to the battery; the battery is connected to the current detection device through the current control device, the current detection device is electrically connected to the mowing equipment, and the current detection device is electrically connected to the DC generator through the controller; The grass equipment includes a drive motor, and the drive motor includes a speed sensor arranged on its output shaft; the speed sensor is electrically connected to the current control device through a controller, and the controller is used to obtain the speed value of the speed sensor, when the speed value is less than the preset speed threshold, inc...

Embodiment 2

[0048] The difference between the second embodiment and the first embodiment is that a lawn mower further includes an impeller, a coupling, a switch, a humidity sensor and a temperature sensor.

[0049] The impeller includes a power shaft and blades connected to the power shaft;

[0050] The output shaft is connected with the power shaft through a coupling;

[0051] The current control device is electrically connected to the drive motor through a switch;

[0052] A rotational speed sensor is provided on the power shaft, and the rotational speed sensor on the power shaft and the rotational speed sensor on the drive motor are respectively electrically connected to a switch through a controller, so as to be used as a switch between the rotational speed sensor on the power shaft and the rotational speed sensor on the drive motor. When the difference of the rotational speed is greater than the preset threshold, the controller controls the switch to be disconnected;

[0053] The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com