Method for correcting and controlling impacts of water content in fuel on loads of boiler

A boiler load and boiler operation technology, applied in the control of combustion, lighting and heating equipment, etc., can solve problems such as unfavorable boiler feed rate automatic control, insufficient boiler output, and heat fluctuations in the furnace, so as to improve boiler operation efficiency and improve The effect of control, the effect of stabilizing the boiler load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

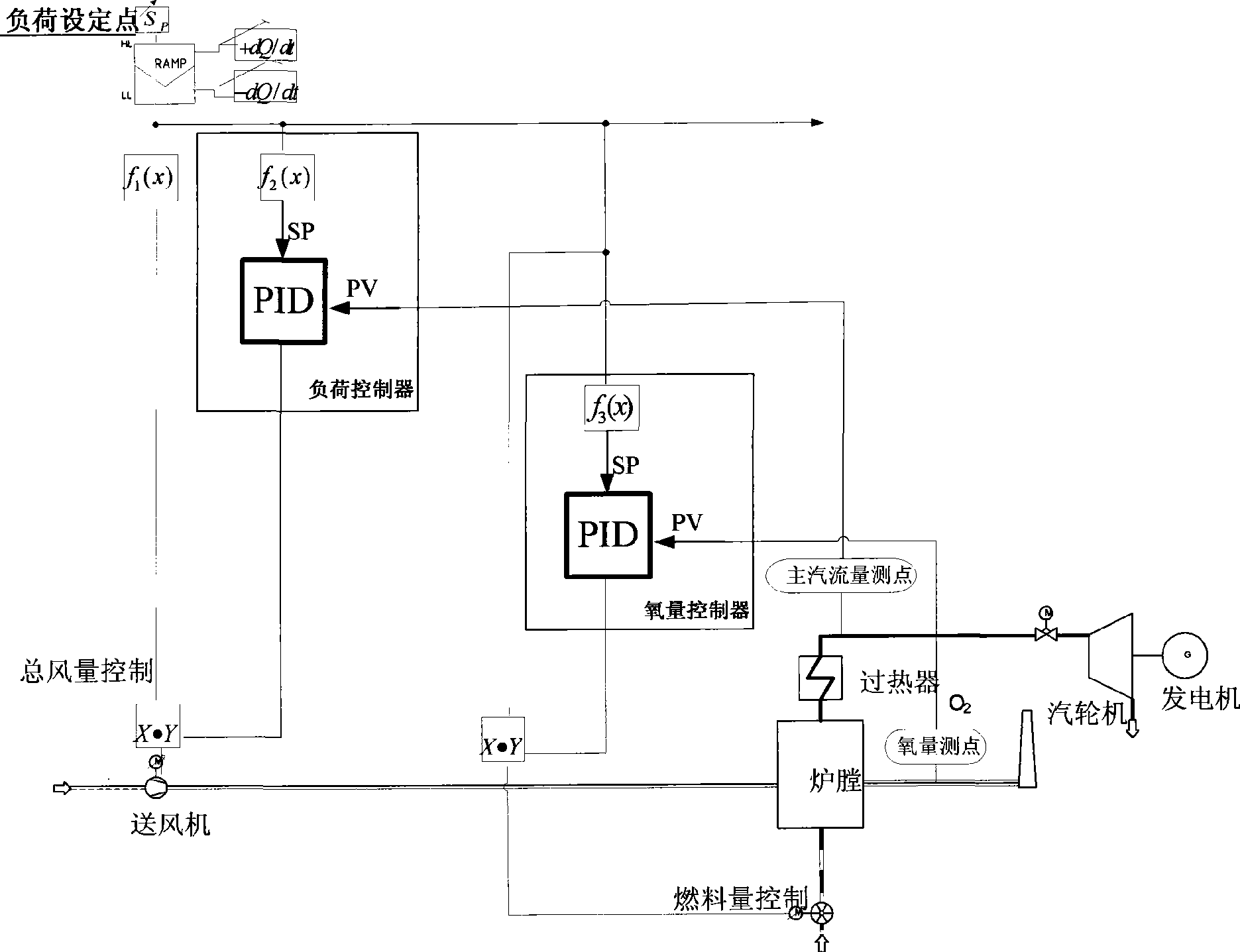

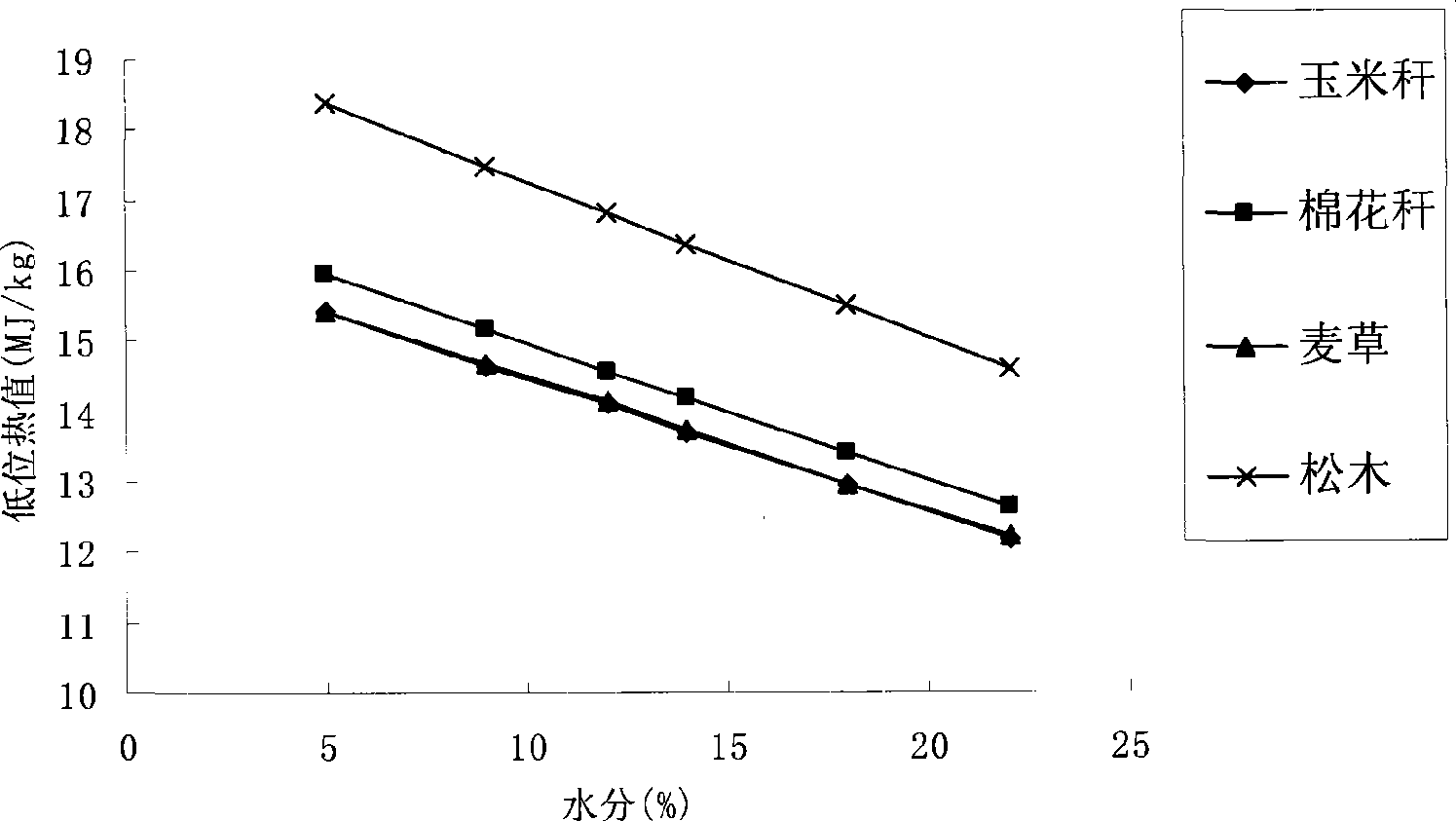

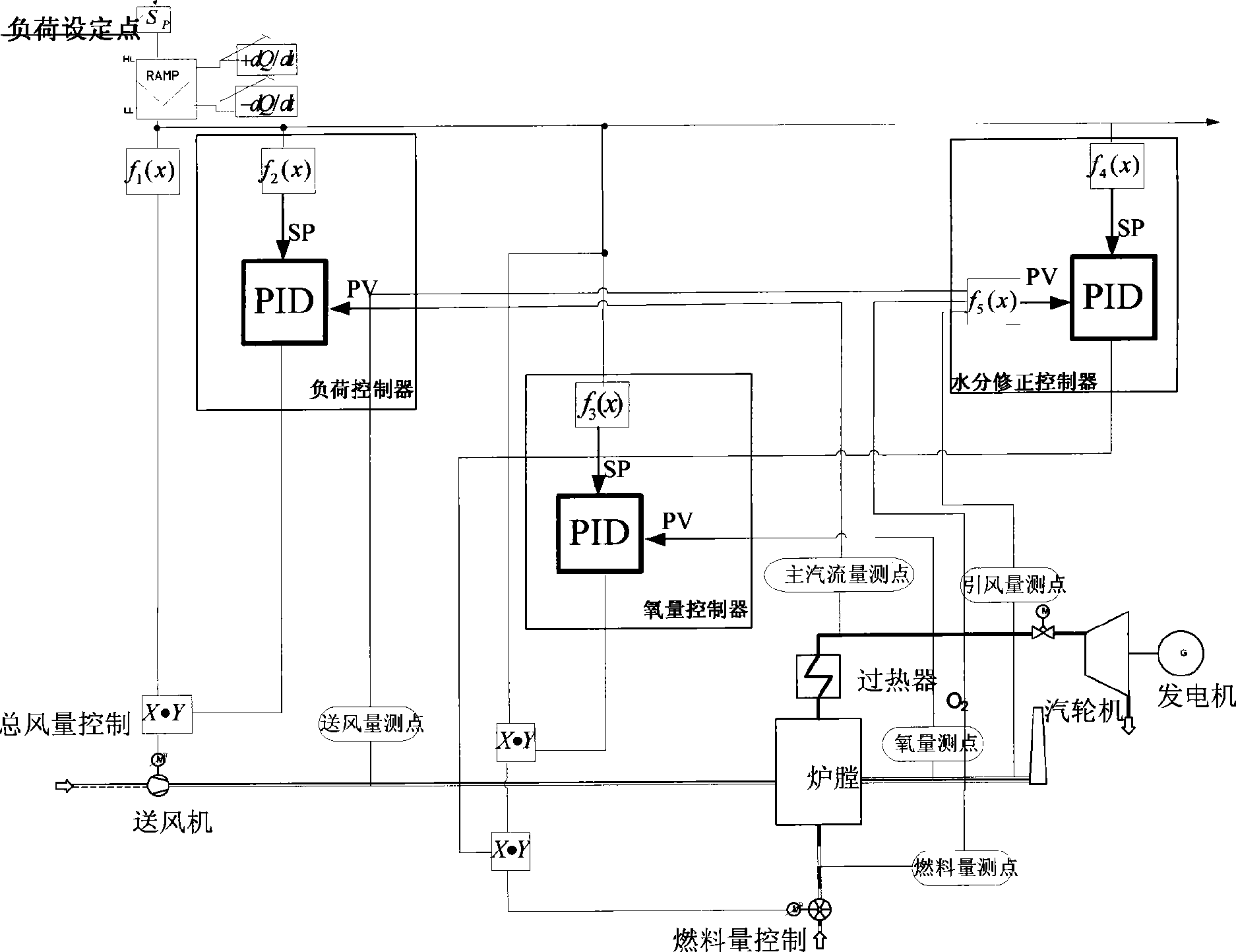

[0024] The present invention aims at the bad influence caused by the moisture content of biomass fuel on boiler load control, introduces the moisture content of biomass fuel as an entry point for improving boiler load control, and constructs a closed-loop PID controller for heat according to the relationship between fuel moisture and calorific value , as attached image 3 shown. According to the boiler load, the heat required to heat the boiler feed water to the rated parameters can be calculated, and this heat can be used as the set value of the closed-loop control; according to the nature of the designed fuel and the structural parameters of the boiler design, the boiler feed volume, delivery Air volume and induced air volume, use thermodynamic calculation method to calculate the moisture content of biomass fuel, and then calculate the heat that the input fuel can provide according to the relationship between fuel moisture content and low calorific value, and use this heat a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com