Extrusion large-injection amount injection moulding device and use method thereof

A technology of injection molding and injection volume, applied in the field of injection molding machines, can solve the problems of high manufacturing cost, waste of materials, long residence time, etc., and achieve the effects of good versatility, improved injection efficiency, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

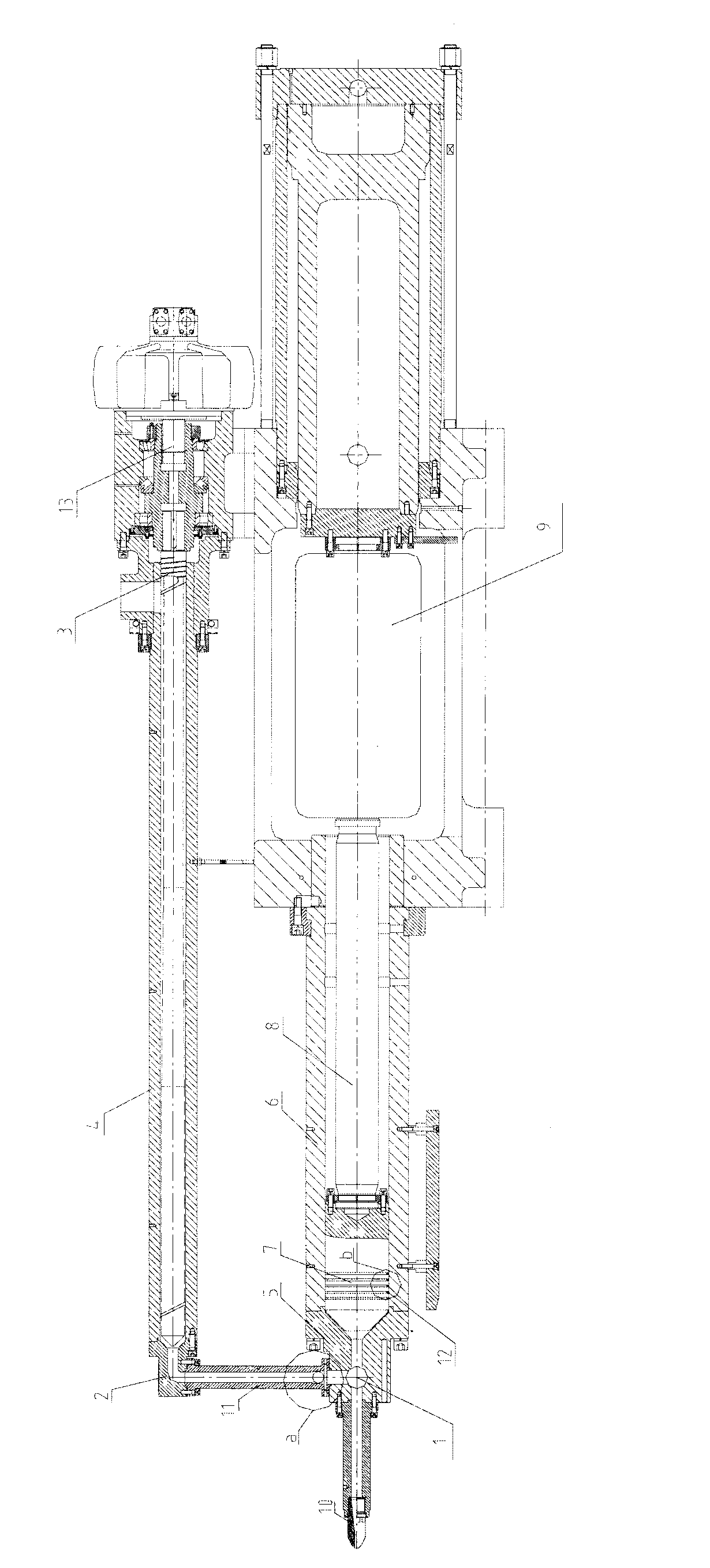

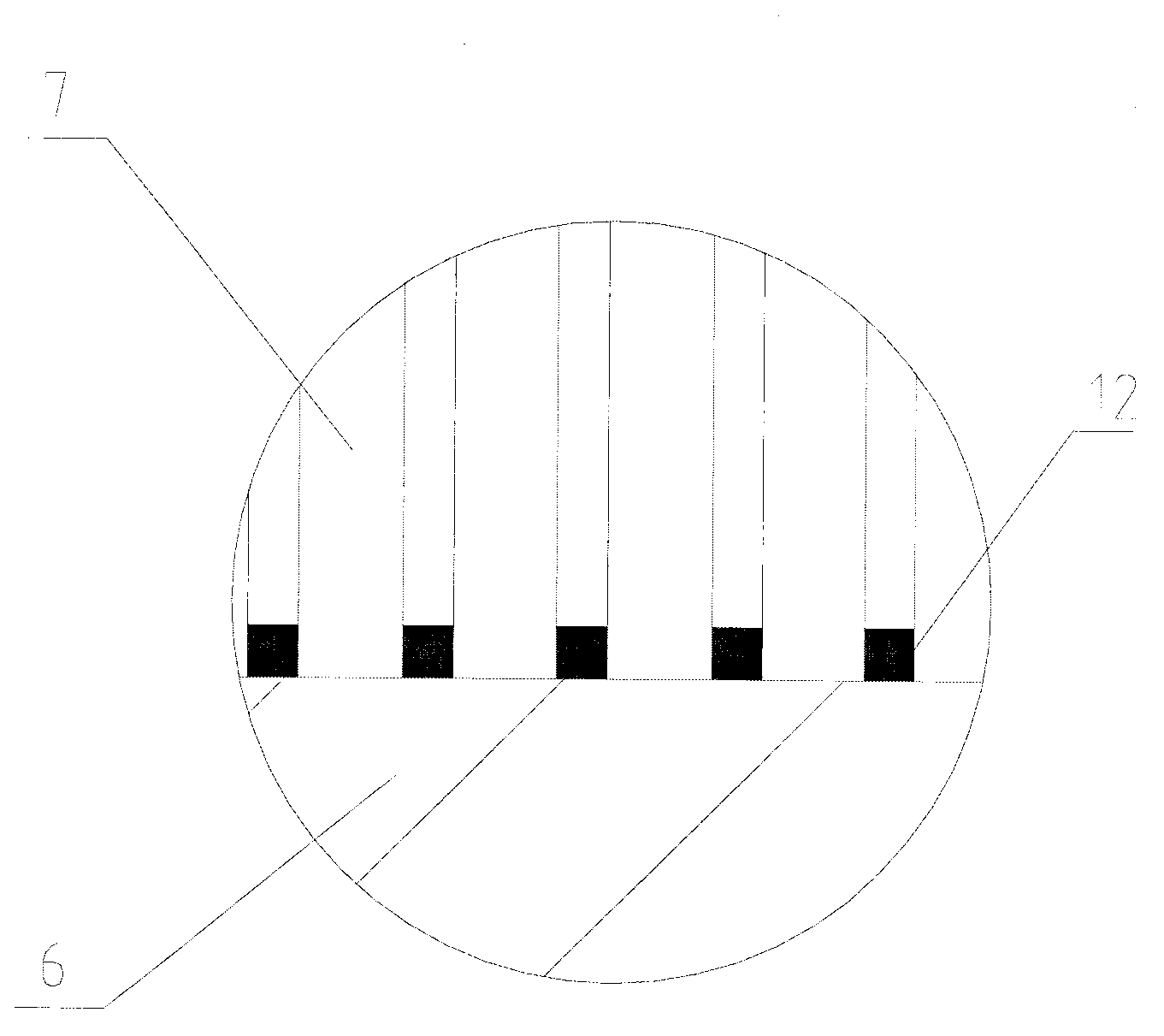

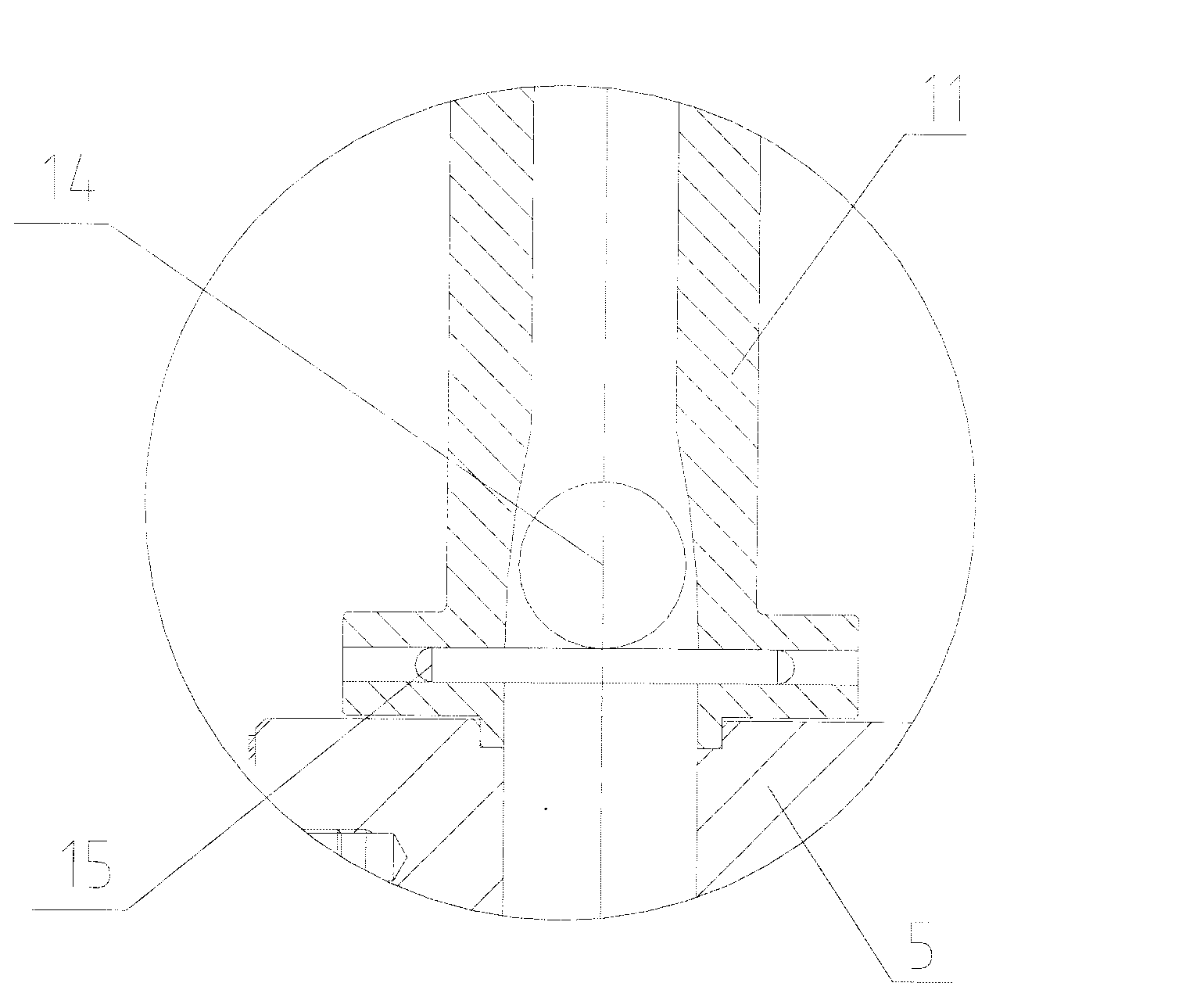

[0032] Such as figure 1As shown, the extrusion-type large injection volume injection molding device of the present invention includes a pre-injection storage mechanism, an injection mechanism, a nozzle 10 and a three-way valve 1, and the pre-injection storage mechanism includes a pre-plastic cylinder 2, Screw 3 and pre-plastic barrel 4, the screw 3 is set in the pre-plastic barrel 4, the injection mechanism includes a pre-injection barrel 5, an injection barrel 6, a piston rod 8 sleeved with a piston 7 and an electro-hydraulic System 9, the piston rod 8 is set in the injection barrel 6, the electro-hydraulic system 9 is connected to the piston rod 8; the pre-shot storage mechanism and the injection mechanism are connected to the nozzle 10 through the three-way valve 1 connect.

[0033] The first melt pressure sensor P is installed in the pre-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com