An automatic drilling machine for underwater pipelines

An underwater pipeline and drilling machine technology, applied in the direction of boring/drilling, drilling/drilling equipment, metal processing equipment, etc. Underwater operation, application of flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following examples describe the present invention in more detail.

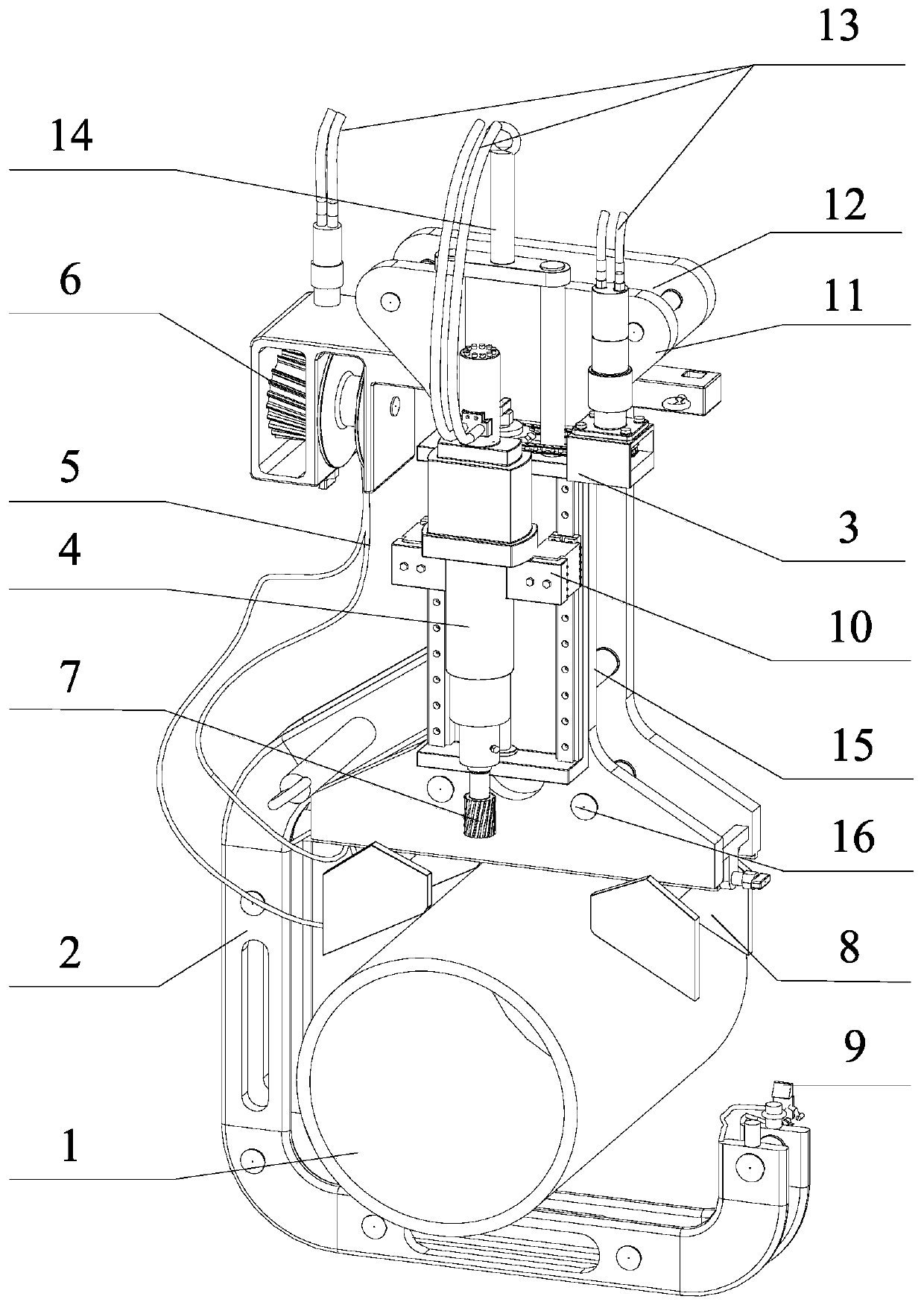

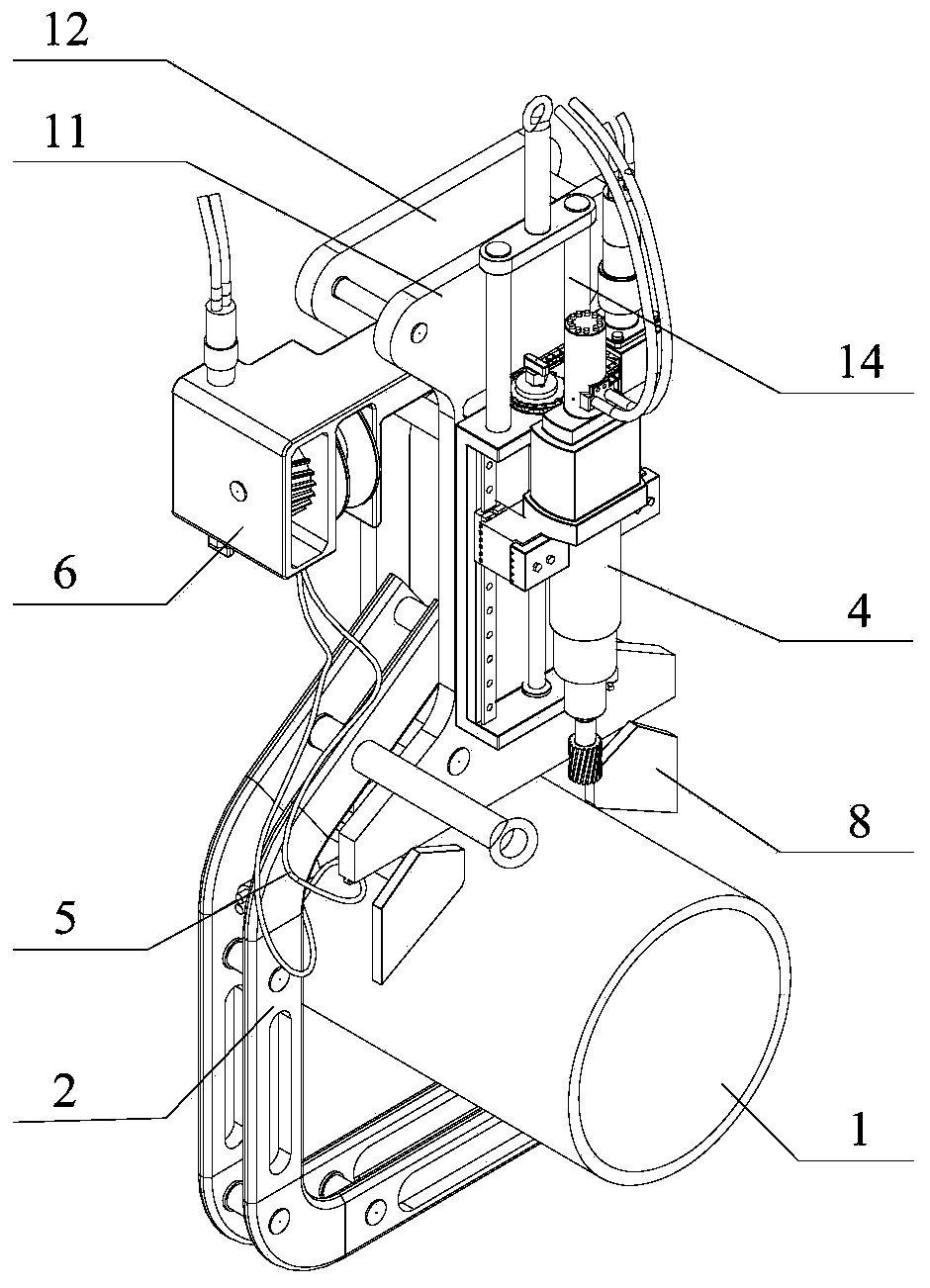

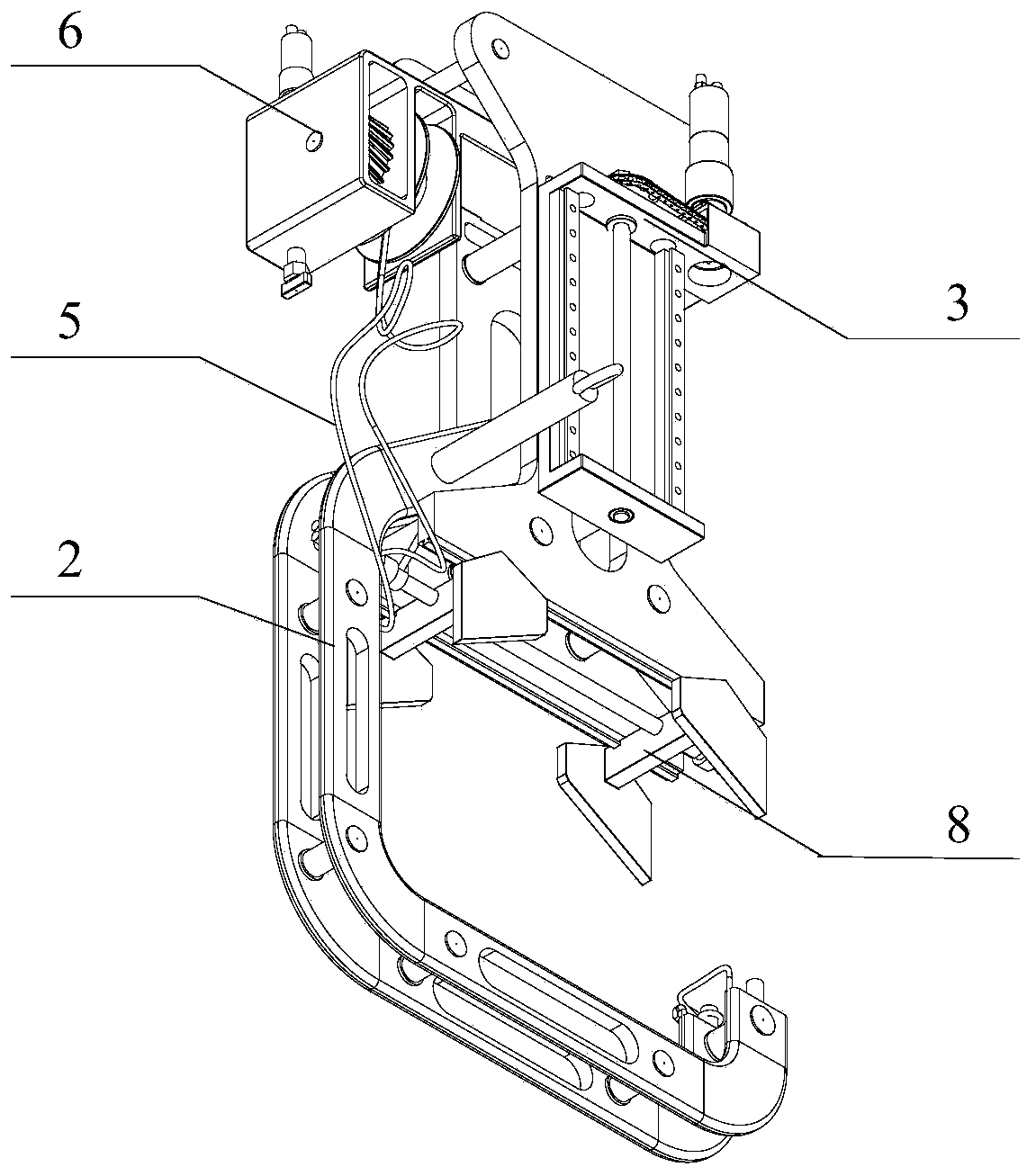

[0042] The implication of each reference sign of the present invention is:

[0043] 1. Underwater pipeline, 2. Wire rope guiding mechanism, 3. Feed driving mechanism, 4. Drilling driving mechanism, 5. Steel wire rope, 6. Clamping mechanism, 7. Drill bit, 8. Pipe positioning mechanism, 9. Wire rope guiding Block, 10. drilling drive mechanism support frame, 11. upper bracket, 12. lower bracket, 13. hydraulic oil pipe, 14. hoisting ring, 15 and 16. upper and lower bracket connecting pin shaft, 201. lead frame, 202. pin shaft , 203. Wire rope guiding mechanism operating handle, 204. Guiding mechanism positioning boss, 205. Steel wire rope storage groove, 301. Support seat, 302. Feed motor, 303. Slide rail, 304. Feed screw, 305. Nut Fixed frame, 306. Chain, 307. T-shaped ROV knob adjustable by wrench, 308. Large sprocket, 309. Small sprocket, 310. Key, 601. Wire receiving bracket, 602. Locking ring, 603...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com