Drilling equipment with dustproof function for municipal building

A technology for drilling equipment and construction, which is applied in the field of drilling equipment for municipal buildings, and can solve problems such as being difficult to clean, falling on the wall, and bodily injury.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

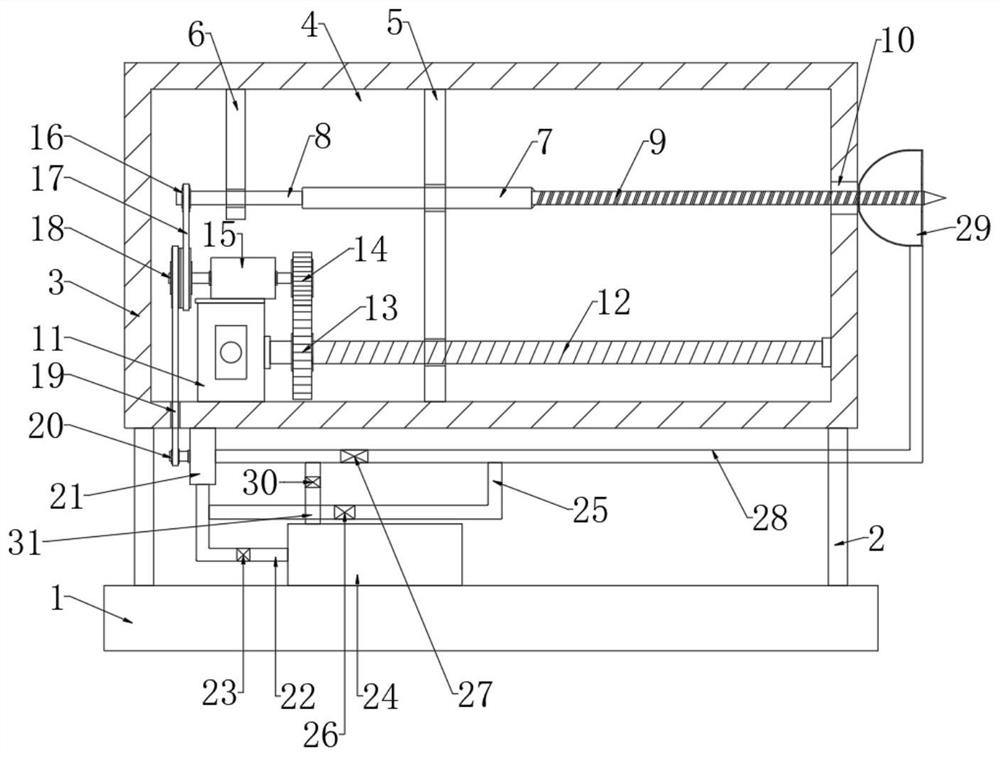

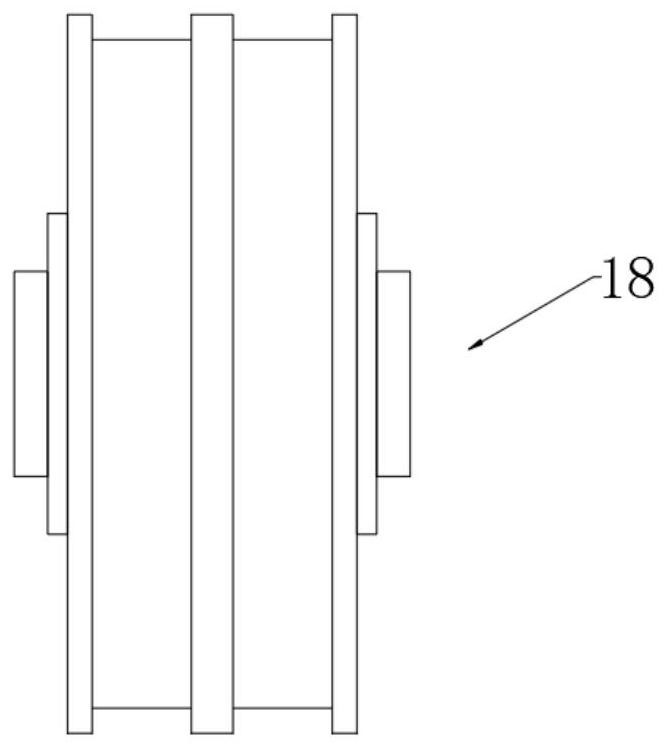

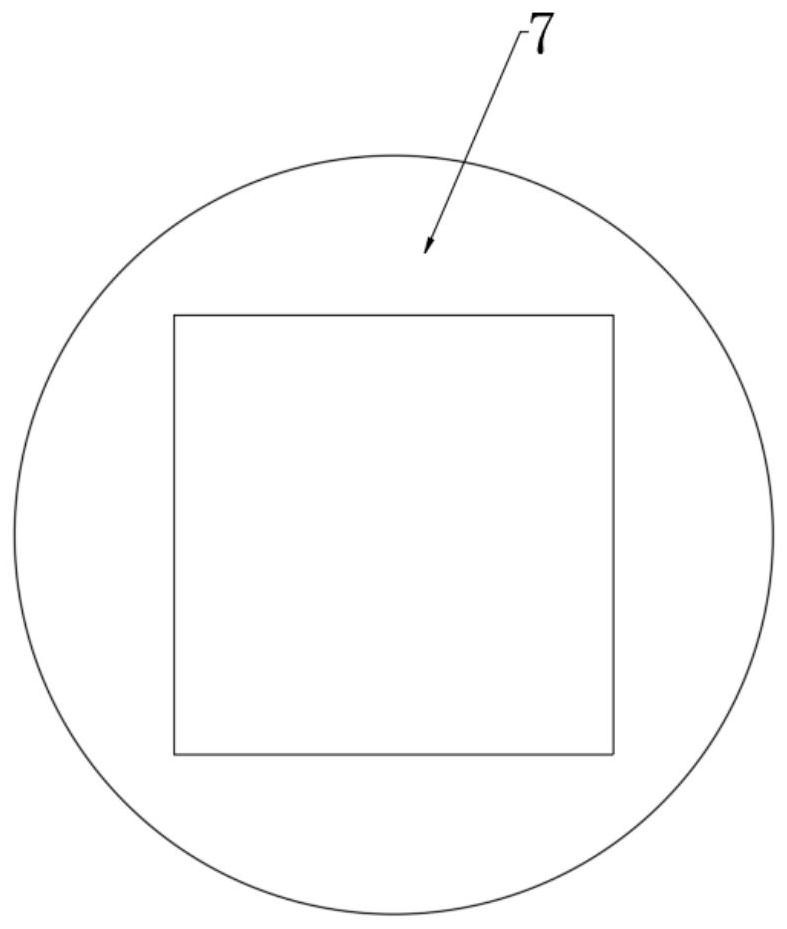

[0028] refer to Figure 1-3 , a kind of drilling equipment for municipal buildings with dustproof function, comprising a base 1, the base 1 can be installed on the lifting frame, so that the height of the drill bit 9 can be adjusted, and the drilling operation can be performed on positions of different heights; the base 1 Four support columns 2 are fixedly connected, and the upper ends of the four support columns 2 are fixedly connected with a box body 3, and the box body 3 is provided with an installation cavity 4, and the inner bottom of the installation cavity 4 is fixedly connected with a servo motor 11, and the servo motor 11 The output end of the screw rod 12 is fixedly connected with it, and the other end of the screw rod 12 is connected with the inner wall of the installation cavity 4 in rotation.

[0029] There is a riser 5 slidingly connected in the installation cavity 4, that is, from figure 1 It can be seen that the vertical board 5 can slide left and right. In ac...

Embodiment 2

[0040] refer to Figure 4-6 The difference between this embodiment and Embodiment 1 is that in this embodiment, the end of the suction cover 39 opposite to the box body 3 is provided with an annular groove 39, and an annular airbag 40 is installed in the annular groove 39, and the inner wall of the installation cavity 4 is fixed. Connected with a piston cylinder 36, the piston cylinder 36 is slidingly connected with a piston 37, the piston cylinder 36 communicates with the annular air bag 40 through the gas delivery pipe 38, and the opposite end of the piston 37 and the gas delivery pipe 38 is fixedly connected with a piston rod 35, and the piston rod 35 The other end of the second hollow rod 33 is fixedly connected with the second hollow rod 33, and the driving rod 32 is slidably connected with the vertical plate 5. The driving rod 32 and the second hollow rod 33 are fixedly connected with a spring 34.

[0041] In this embodiment, when the vertical plate 5 moves, the vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com