Perforation drill bit for lunch box die

A technology for fast food boxes and drills, which is applied in the direction of boring/drilling, drilling/drilling equipment, manufacturing tools, etc. It can solve the problems of high labor intensity, large number of drilling holes, and tediousness, so as to reduce labor intensity and adapt The effect of promoting application and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

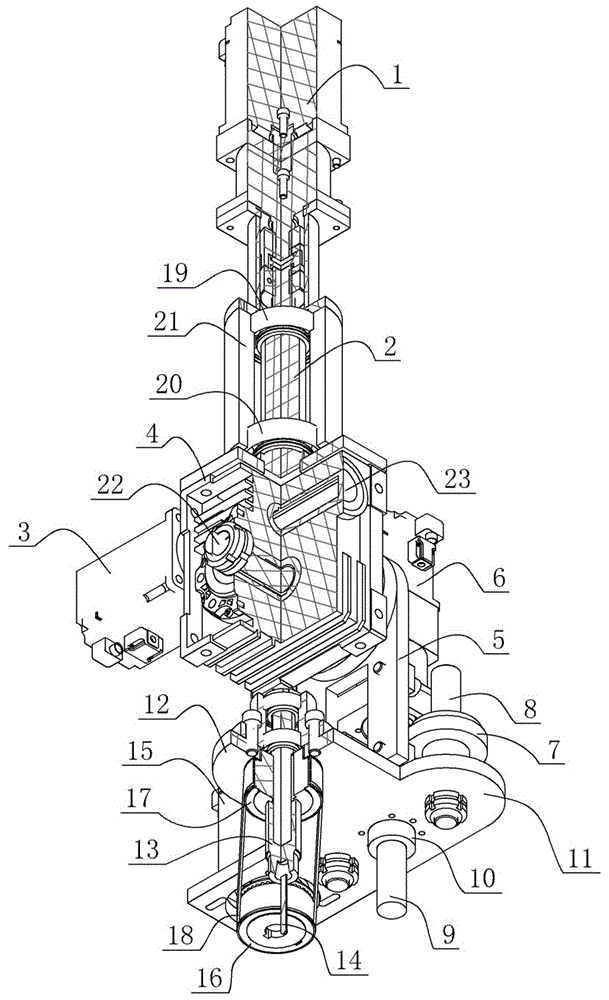

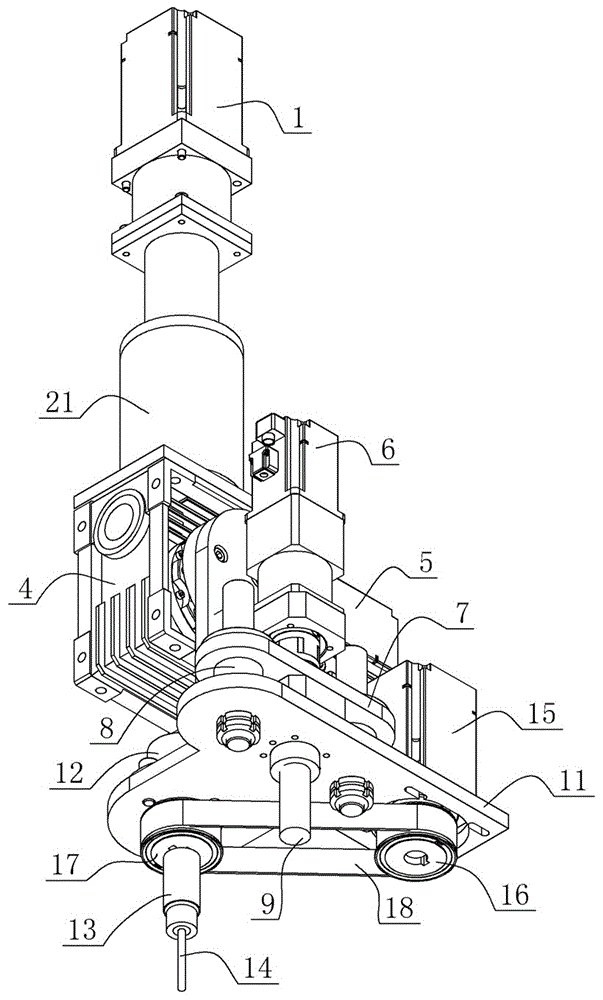

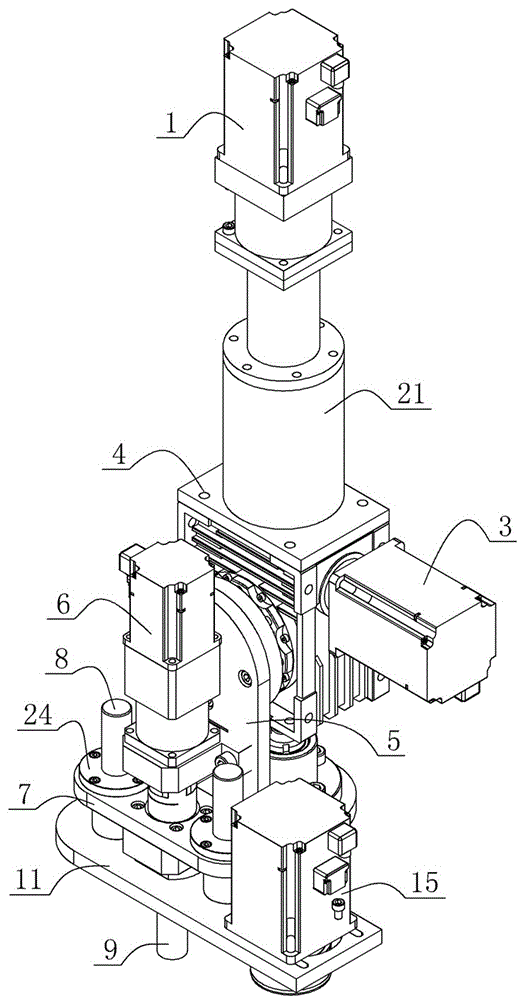

[0018] Such as figure 1 Shown, the sectional view of fast food box mold perforating drill bit of the present invention is provided, as figure 2 and image 3 As shown, the perspective view of the fast food box mold punching drill bit of the present invention is provided, which includes a rotary motion mechanism, a swing motion mechanism, a forward and backward motion mechanism and a drill drive mechanism, and the rotary motion mechanism is composed of a rotary motor 1 and a rotary shaft 2, swinging The motion mechanism is composed of a swing motor 3, a transmission box 4 and a swing arm 5. The periphery of the rotating shaft 2 is a slewing support sleeve 21. The upper and lower parts of the rotating shaft 2 respectively pass through the deep groove ball bearing 19 with a sealing ring and the bearing with a sealing ring. The bearing 20 is fixed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com