Directional variable flow type hydraulic fracturing system and method

A splitting and hydraulic technology, applied in the field of directional variable flow hydraulic splitting systems, can solve the problems of inability to automatically and accurately control the splitting point and splitting timing and the high splitting pressure, experience and technical requirements, and achieve fixed The effect of stability, high security and low error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

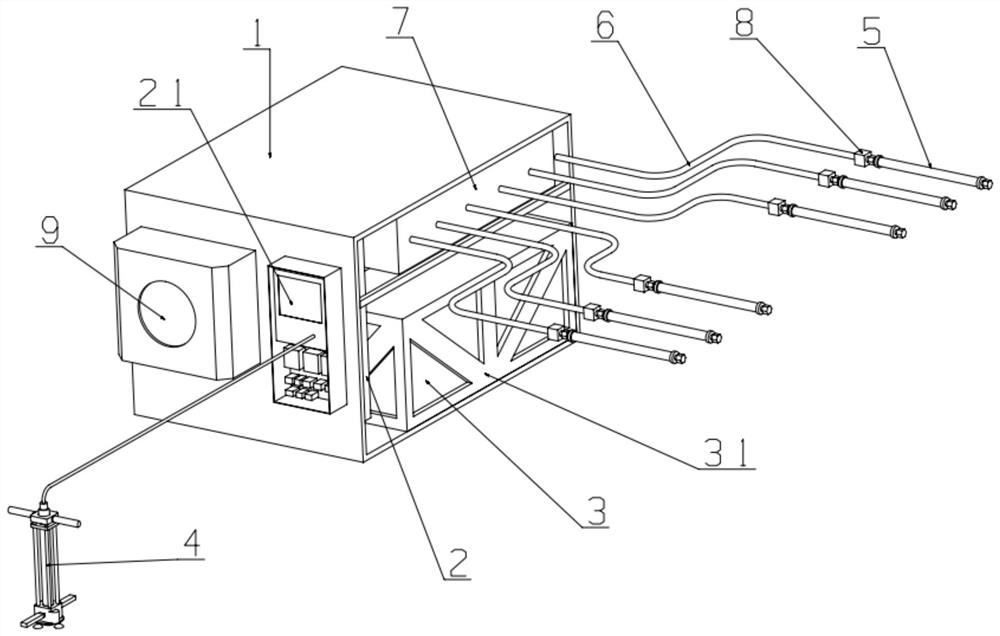

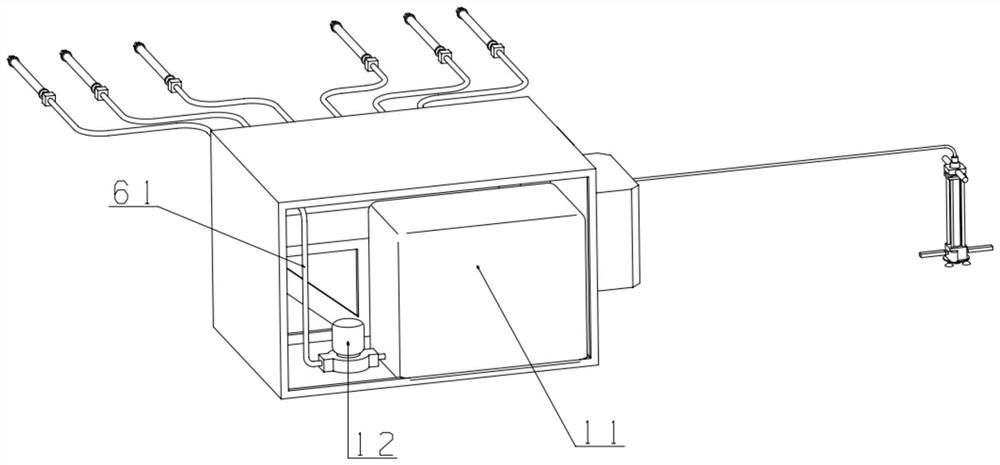

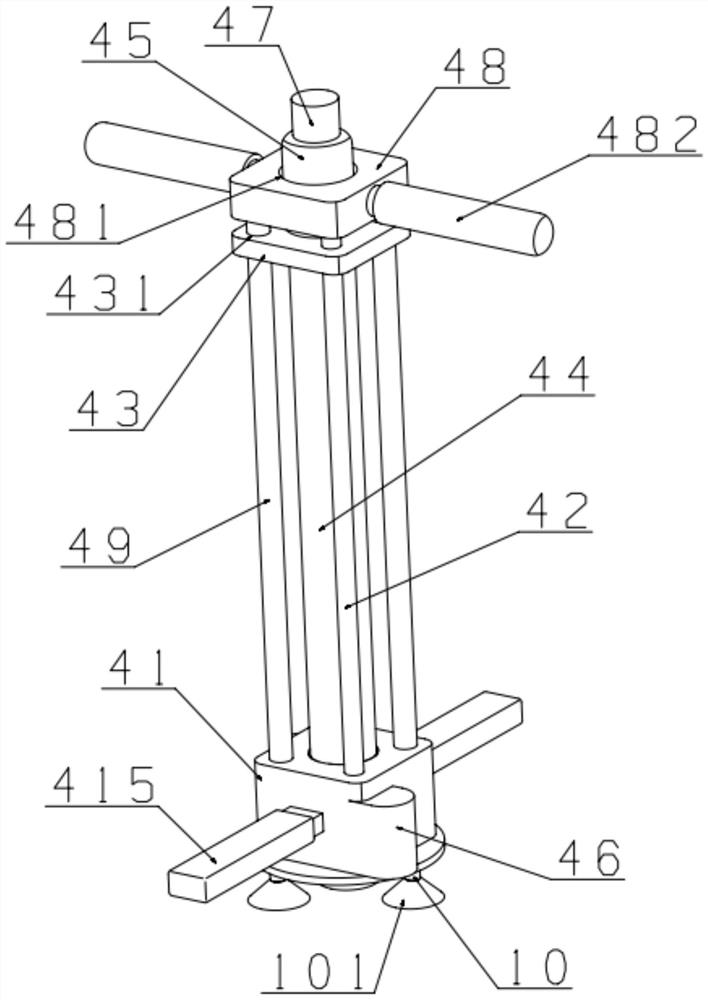

[0051] Such as Figure 1 to Figure 5 As shown, the directional variable flow hydraulic splitting system in this embodiment includes: a main machine box 1, a water tank 11, a booster pump 12, a main controller 2, an operating console 21, a storage battery 3, a shock absorber 31, and a drilling Device 4, frame 41, first end 411, second end 412, first guide hole 413, guide bar 414, first handle 415, guide rail 42, drill seat 43, screw hole 431, drill bit 44, first motor 45 , second motor 46, sub-controller 47, auxiliary seat 48, second guide hole 481, second handle 482, screw 49, expander 5, expansion tube 51, quick connector 52, first water pipe 6, second water pipe 61 , Distribution valve 7, water pressure sensor 8, air conditioner 9, foot 10, foot pad 101.

[0052] The inside of the main box 1 is installed with: a water tank 11, a booster pump 12, a main controller 2, a battery 31 and a distribution valve 7; the main controller 2 is electrically connected to the battery 31 an...

Embodiment 2

[0056] Such as Figure 6 As shown, the directional variable flow hydraulic splitting method in this embodiment is realized by the directional variable flow hydraulic splitting system in the above embodiment, and specifically includes the following steps:

[0057] S1: Path planning, first plan the rock splitting path and the splitting timing of each splitting point according to the construction conditions on site and the direction of the stone falling, and mark it on the rock wall;

[0058] S2: Drilling and data acquisition, the rock wall is drilled with the marking point on the rock wall of the drilling device 4, and the torque of the first motor 45 and the second motor 46 is collected by the secondary controller 47, and the data is collected. It is transmitted to the main controller 2, and the rock formation hardness at each marked point is obtained through the calculation of the main controller 2, and the cracking critical pressure value at the marked point is calculated at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com