Building template automatic drilling machine and operating method

A construction template, drilling machine technology, applied in the direction of boring/drilling, drilling/drilling equipment, metal processing machinery parts, etc., can solve the problem of low work efficiency, high labor intensity of operators, and poor drilling quality. Good guarantee and other issues to achieve the effect of reducing labor intensity, improving drilling efficiency and drilling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

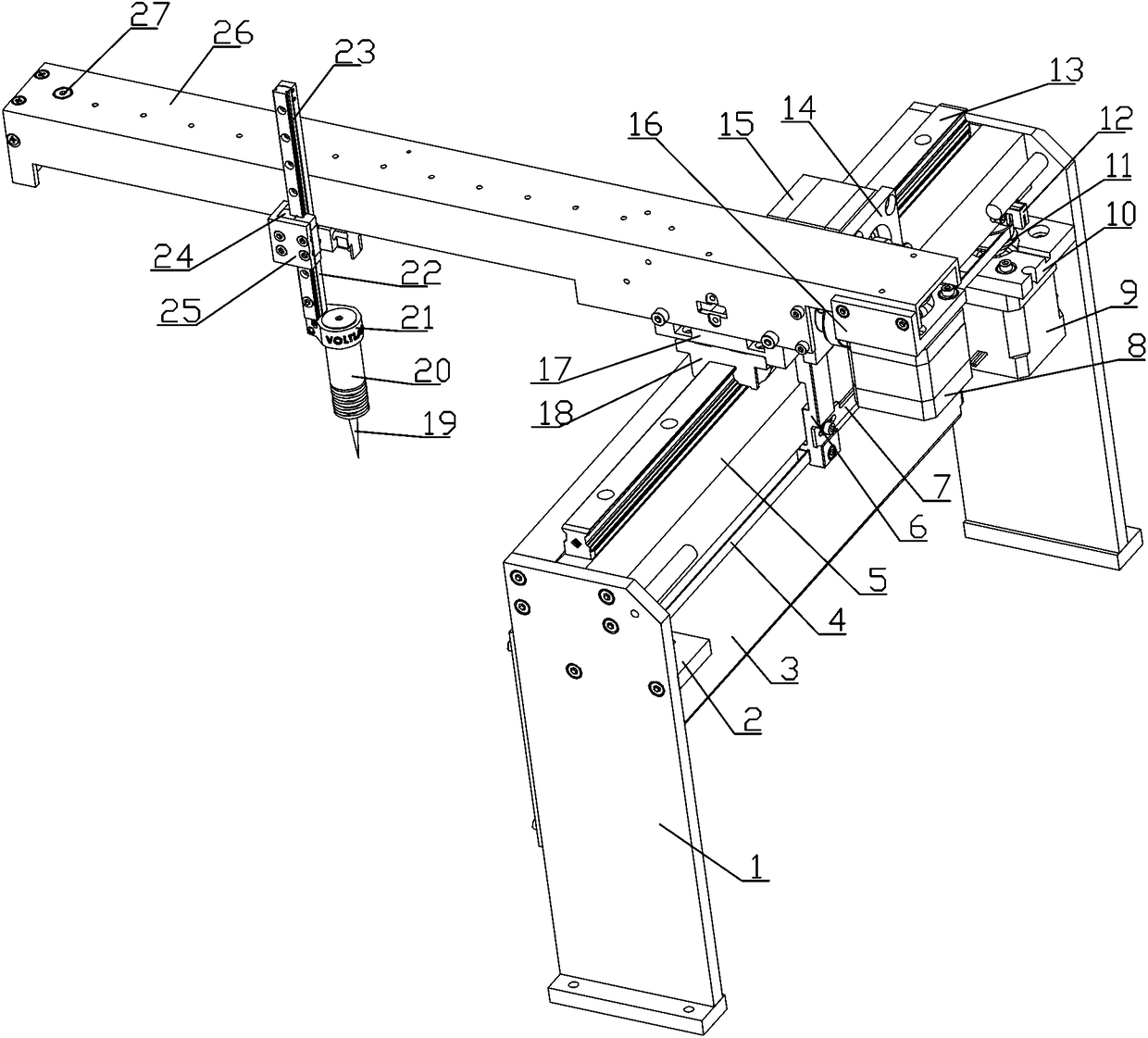

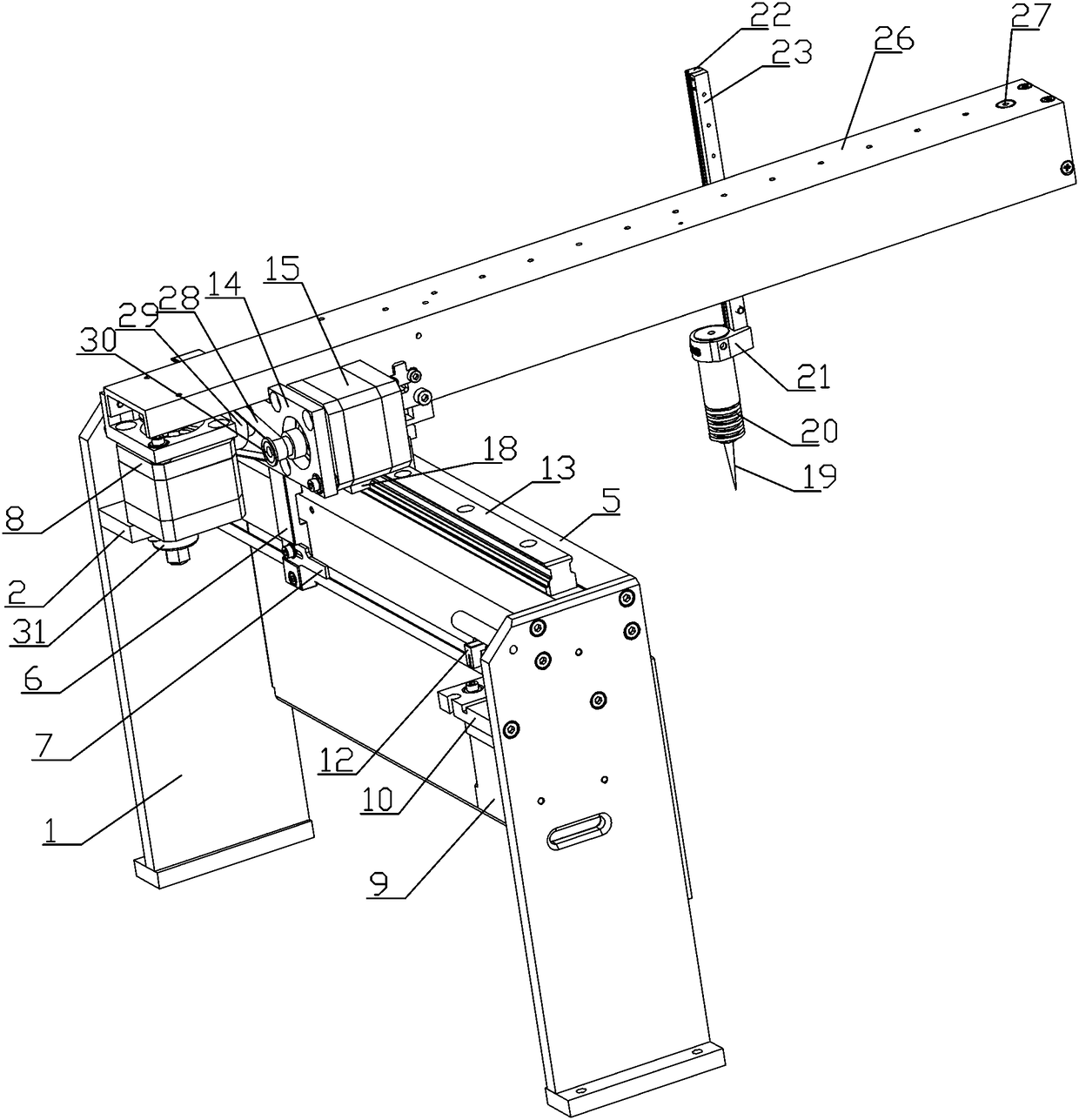

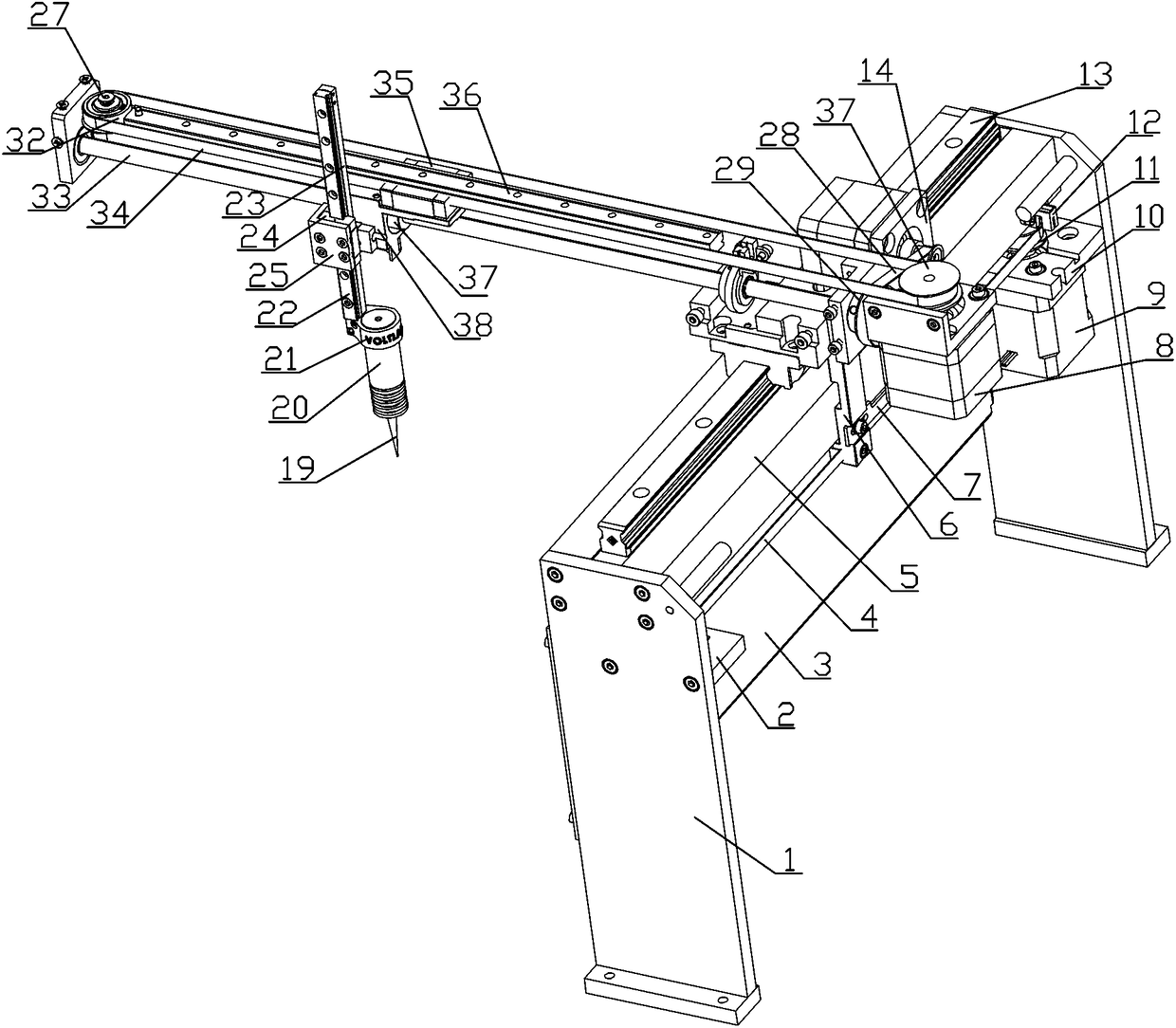

[0037] see Figure 1-5 , building formwork automation drilling machine, it comprises the frame plate 1 that symmetrical arrangement is arranged, and the top of frame plate 1 is fixed with crossbeam 5, and the top of described crossbeam 5 is equipped with transverse slide rail 13, and on described transverse slide rail 13 Sliding fit is equipped with slide block 18, and the top of described slide block 18 is fixed with transverse sliding plate 17, and vertical connecting plate 6 is installed on the side wall of described transverse sliding plate 17, and described vertical connecting plate 6 and The transverse power device used to drive the movement of the transverse sliding plate 17 is connected; the side wall of the transverse sliding plate 17 is fixed with a longitudinal motor mounting plate 16, and a horizontally arranged cantilever box is installed on the longitudinal motor mounting plate 16 26. A longitudinal sliding mechanism for providing longitudinal movement is install...

Embodiment 2

[0047] The operating method of any one of the building formwork automation drilling machines, it comprises the following steps:

[0048] Step1: Fix this automatic drilling machine on the side of the building formwork;

[0049] Step2: According to the required drilling position, the PLC controller controls the horizontal movement motor 9 and the longitudinal movement motor 8 respectively, and drives the drilling device to move within the plane range, so that it moves directly above the required drilling position;

[0050] Step3: Control the vertical lifting motor 15 through the PLC controller, drive the drilling device to move up and down through the vertical lifting motor 15, and then control the lifting of the drilling device;

[0051] Step4: Start the drilling machine 20 after the drill bit 19 is in place, and drill the template through the drilling machine 20;

[0052] Step5: After one hole is drilled, proceed to the next hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com