Separating device for dismounting tiles

A technology for separating devices and tiles, which is applied in construction, building maintenance, building construction, etc., to achieve the effect of low equipment cost and exquisite structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

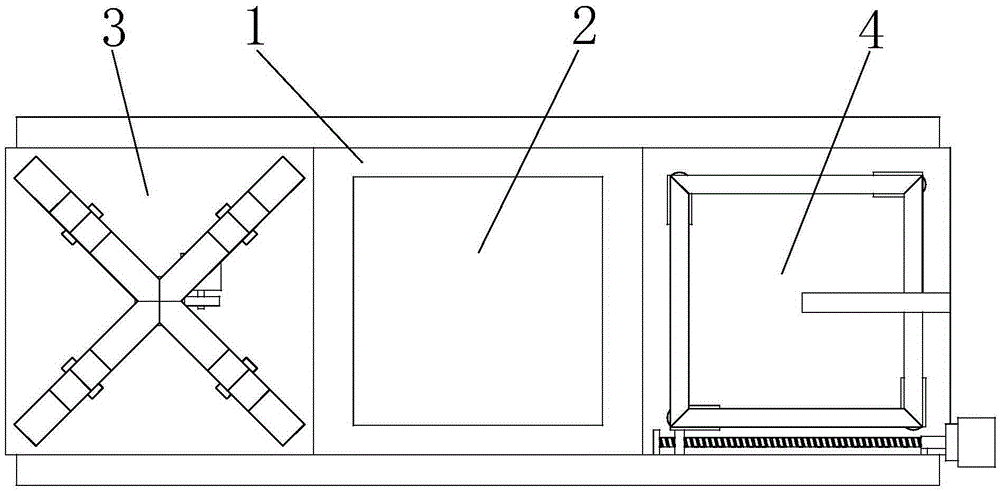

[0026] like figure 1 As shown, a separation device for dismantling tiles mainly includes a horizontal slideway 1 and a positioning groove 1a at the center of the horizontal slideway 1;

[0027] Before the present invention is used, it is necessary to install the present invention directly above the ceramic tile that needs to be disassembled and separated. The specific position can be positioned by the positioning groove 1a. Above the positioning groove 1a, punch holes at the four corners of the tiles and cut and separate the four outer connection edges of the tiles in sequence.

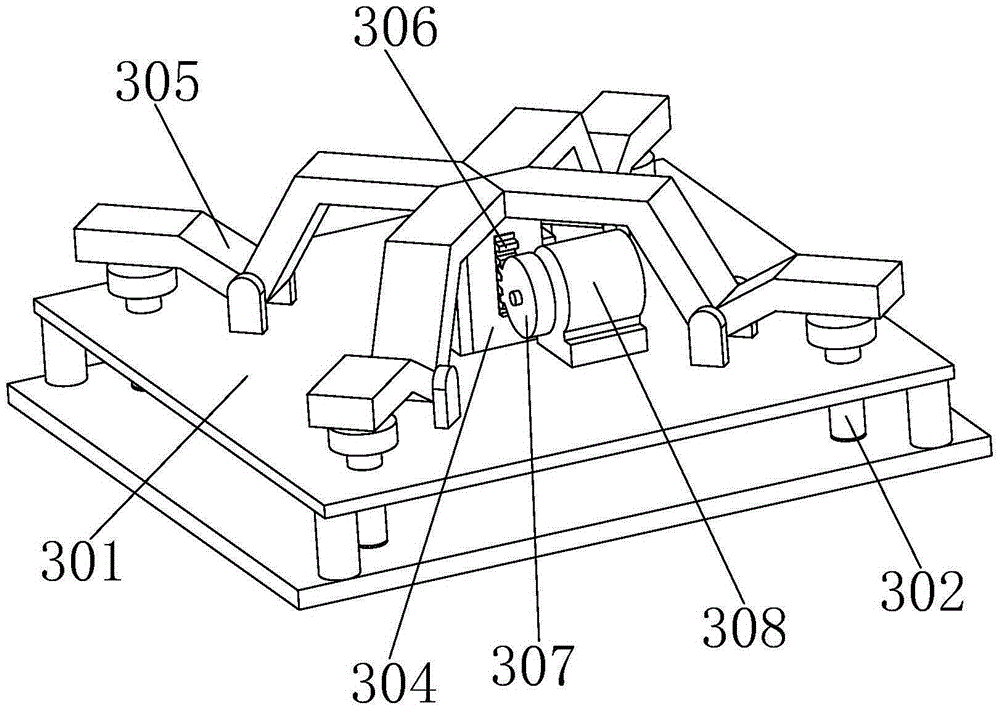

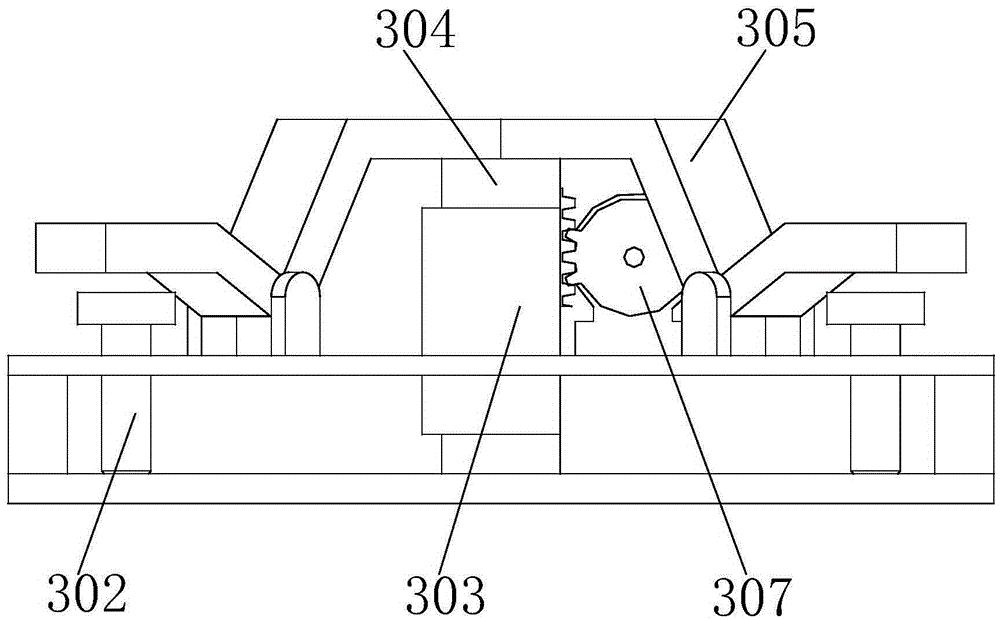

[0028] like Figure 2 to Figure 4 As shown, the drilling device 3 mainly includes a double-layer frame 301 slidably installed on the transverse slideway 1, and hammer nails 302 are installed longitudinally on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com