Rotary drilling rig

A technology for rotary drilling rigs and drill pipes, applied in the field of rotary drilling rigs, which can solve the problems of large friction, large size of rotary drilling rigs, and large output power of drawworks, etc., to achieve outstanding substantive features, reduce equipment costs, and reduce overall machine costs. The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

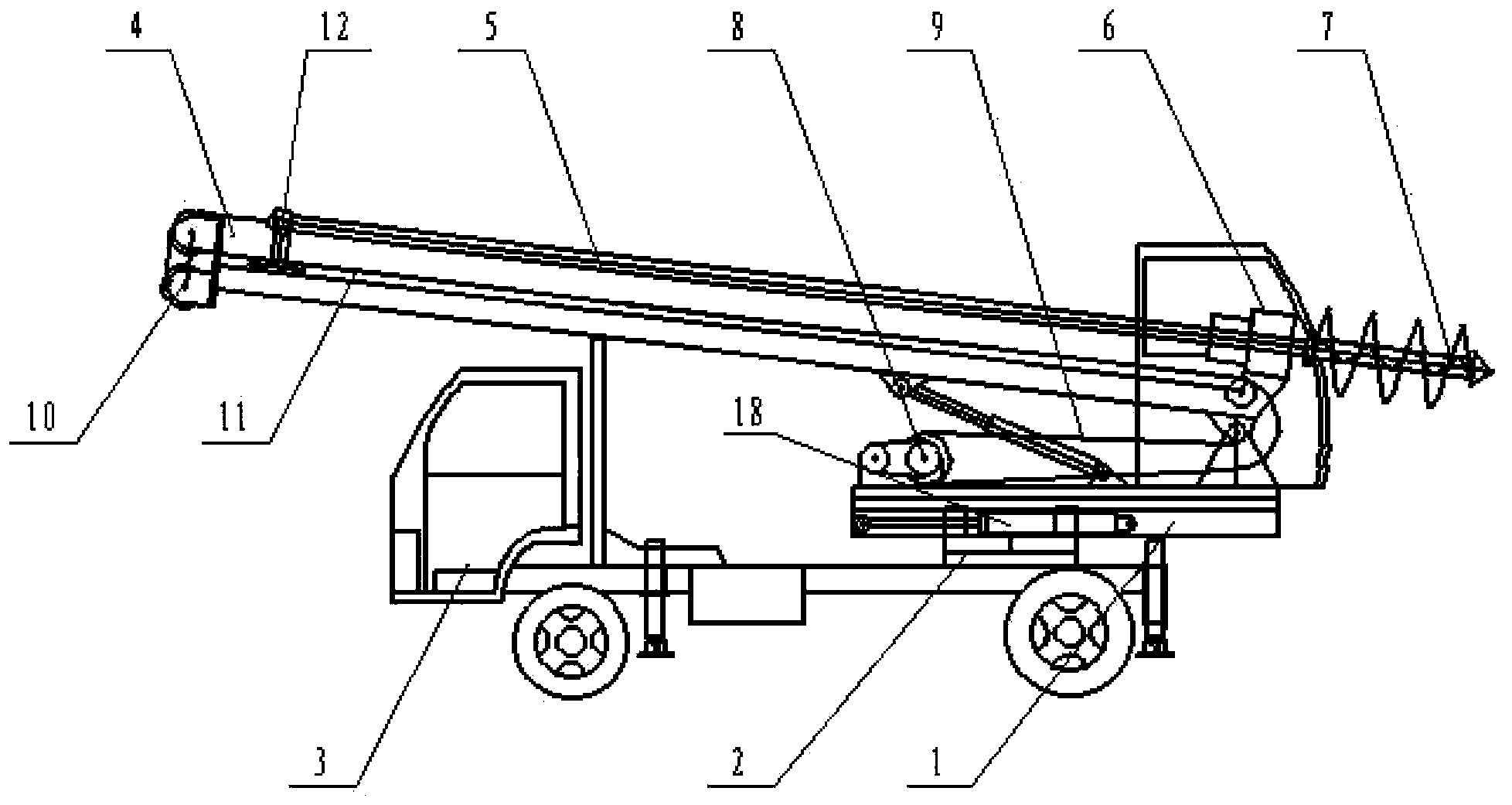

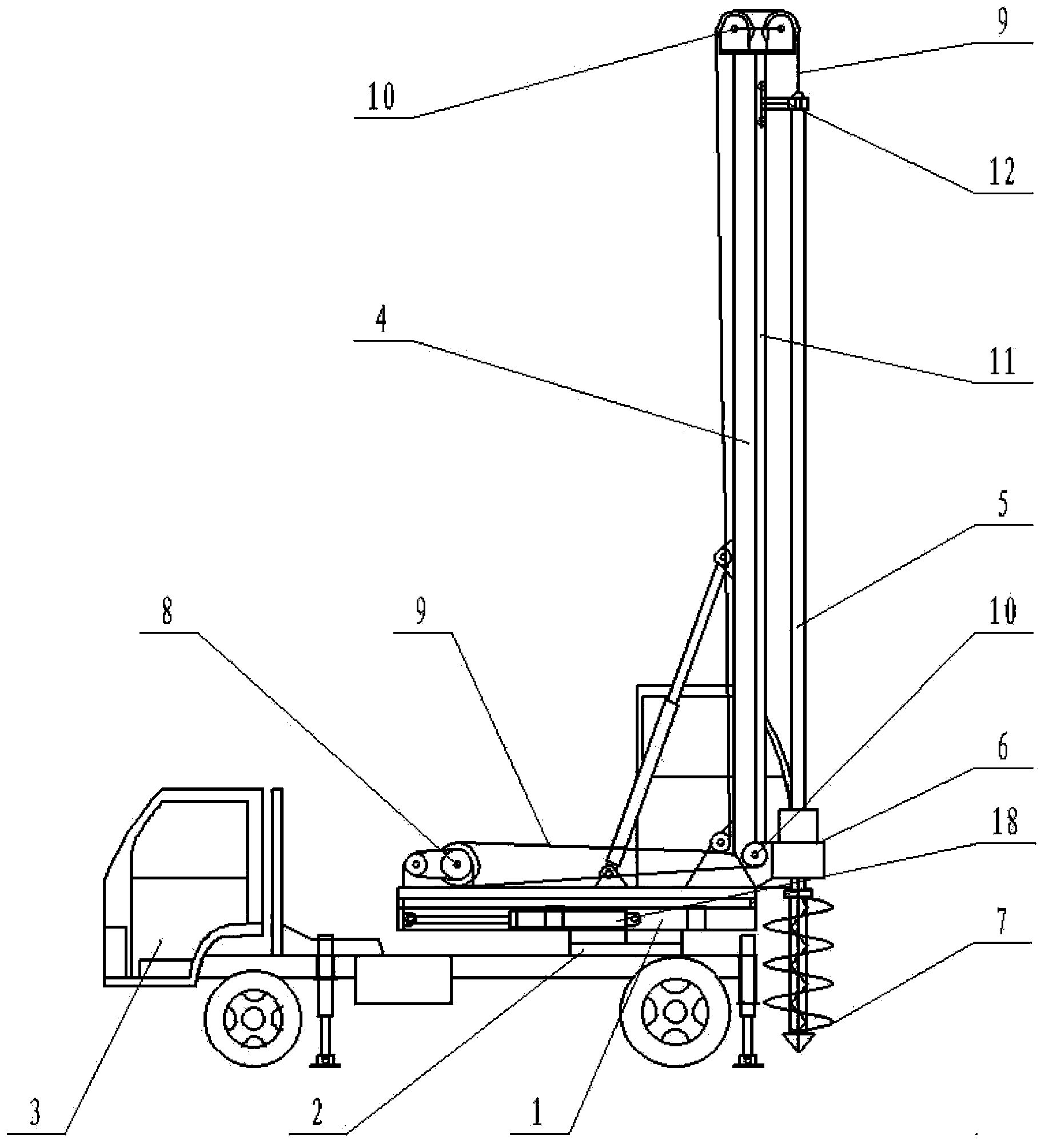

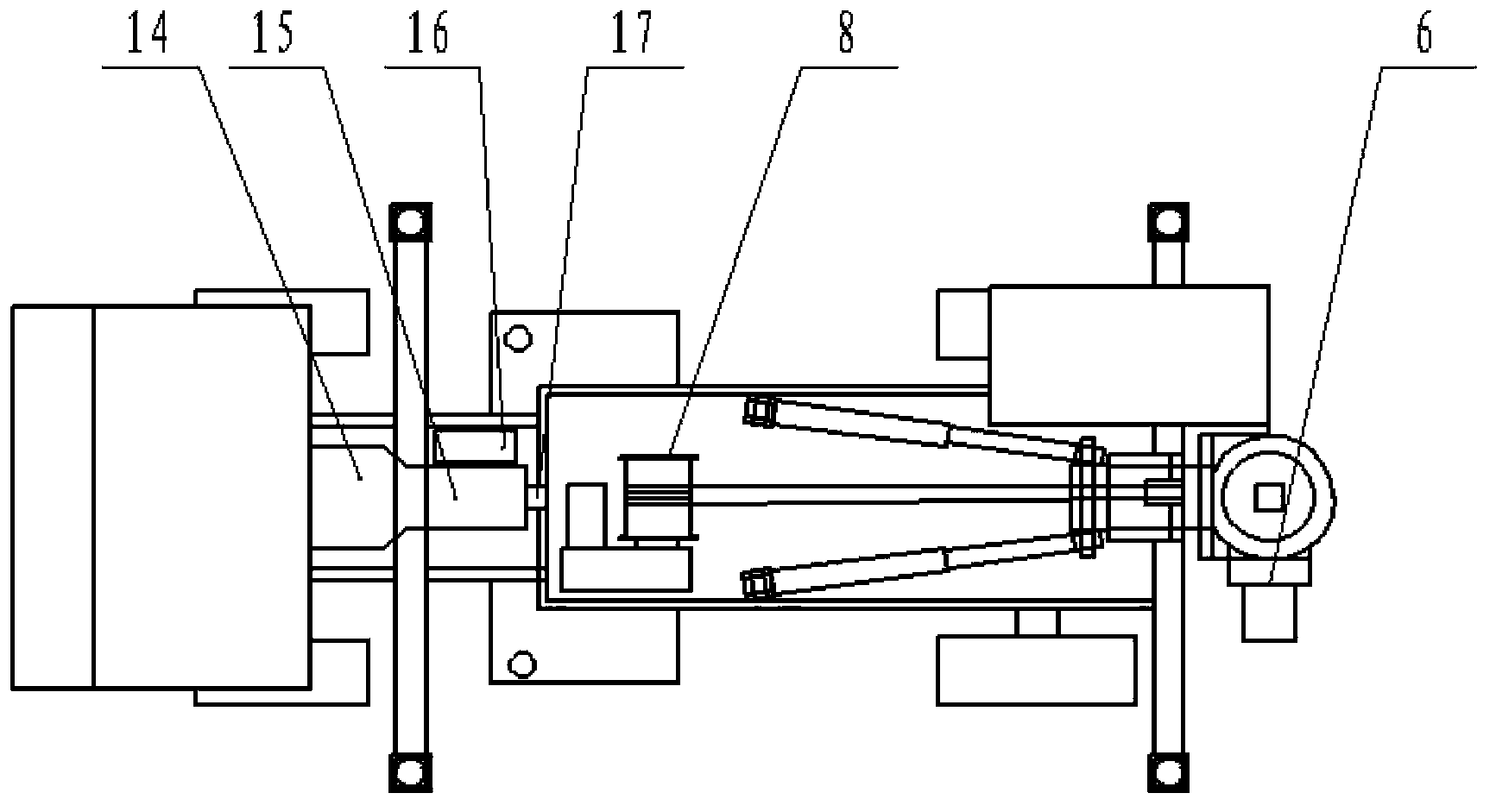

[0033] Such as Figure 1-Figure 4 As shown, a rotary drilling rig includes a driving device composed of an engine 14, a gearbox 15, a power take-off 16 and a two-stage hydraulic oil pump 17. The rotary drilling rig also includes a workbench 1, a column 4, a drill rod 5, a rotating Power head 6, drill bit 7, winch 8, wire rope 9 and pulley 10, column 4 and winch 8 are installed on the workbench 1, and workbench 1 is installed on the tracked vehicle by rotary disc 2. A steel wire rope 9 is wound on the winch 8, a sports car track 11 is arranged on the outside of the column 4, a drill pipe sports car 12 is installed on the sports car track 11, and the two ends of the drill pipe sports car 12 are fixedly connected with the steel wire rope 9 respectively. The wire rope 9 is connected to the drawworks 8 after the pulley 10 at the lower end of the column 4 changes direction respectively, and the drill rod sports car 12 moves up and down along the sports car track 11 under the drive o...

Embodiment 2

[0038] Such as Figure 5-Figure 7 As shown, the difference from the embodiment is that the workbench 1 is installed on the wheeled vehicle through the rotary disc 2, and the wheeled vehicle is a three-wheel drive axle structure, that is, it is driven by the front steering drive axle, the middle bridge and the rear axle. The movement of the workbench 1 makes the rotary drilling rig easy to drive, flexible and has good off-road performance. After the steel wire rope 9 changes direction through the pulley 10 at the lower end of the column 4, it is connected to the winch 8 through a set of pulley blocks, which reduces the power output requirements of the driving device and reduces energy consumption and cost. Drilling rod 5 is square column type, and the middle of rotary power head 6 is provided with the corresponding drilling rod hole that is square with the cross section of drilling rod 6, and drilling rod 5 penetrates in the drilling rod hole. The drill pipe 5 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com