Telescopic drill pipe

A technology of telescopic drill pipes and drill pipes, which is applied in the field of drill pipes and telescopic drill pipes. It can solve the problems that the length of drill pipes cannot be adjusted in real time, and achieve the effects of reducing the time for connecting drill pipes and increasing the drilling speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

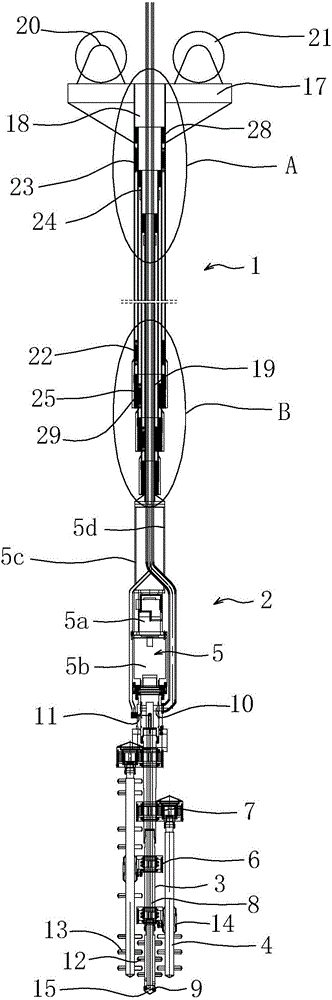

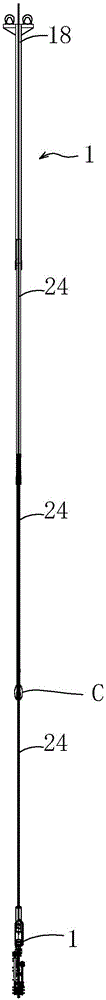

[0035] like figure 1 As shown, a telescopic drill rod includes a drill rod mechanism 1 and a drill bit mechanism 2 fixed at the end of the drill rod mechanism 1. The drill rod mechanism 1 can reciprocate along the axial direction so as to change the length of the drill rod mechanism 1 The drill bit mechanism 2 includes a main drill rod 3 capable of rotating in the circumferential direction and several auxiliary drill rods 4 arranged around the main drill rod 3, at least one auxiliary drill rod 4 rotates in the same direction as the main drill rod 3 and at least The direction of rotation of an auxiliary drill rod 4 is opposite to that of the main drill rod 3 . The auxiliary drill rod 4 and the main drill rod 3 can be distributed in the structure shown in FIG. 12 .

[0036] In this embodiment, an oil cylinder can be installed at the end of the drill rod mechanism 1, and the output end of the oil cylinder is connected to the drill bit mechanism 2. When the oil cylinder works, th...

Embodiment 2

[0051] The structure and working principle of this embodiment are basically the same as that of Embodiment 1, the difference is that, as figure 1 As shown, the air delivery pipe 26 and the material delivery pipe 27 penetrate into the innermost movable drill pipe 24 from the installation platform 17, and penetrate into the main drill pipe 3 all the time, and pass through the main drill from above the main drill pipe rotary driver 5 The rod 3 is connected with the air inlet 11 and the concrete feed port 10 , and the air inlet 11 and the concrete feed port 10 are connected with the conveying channel 8 .

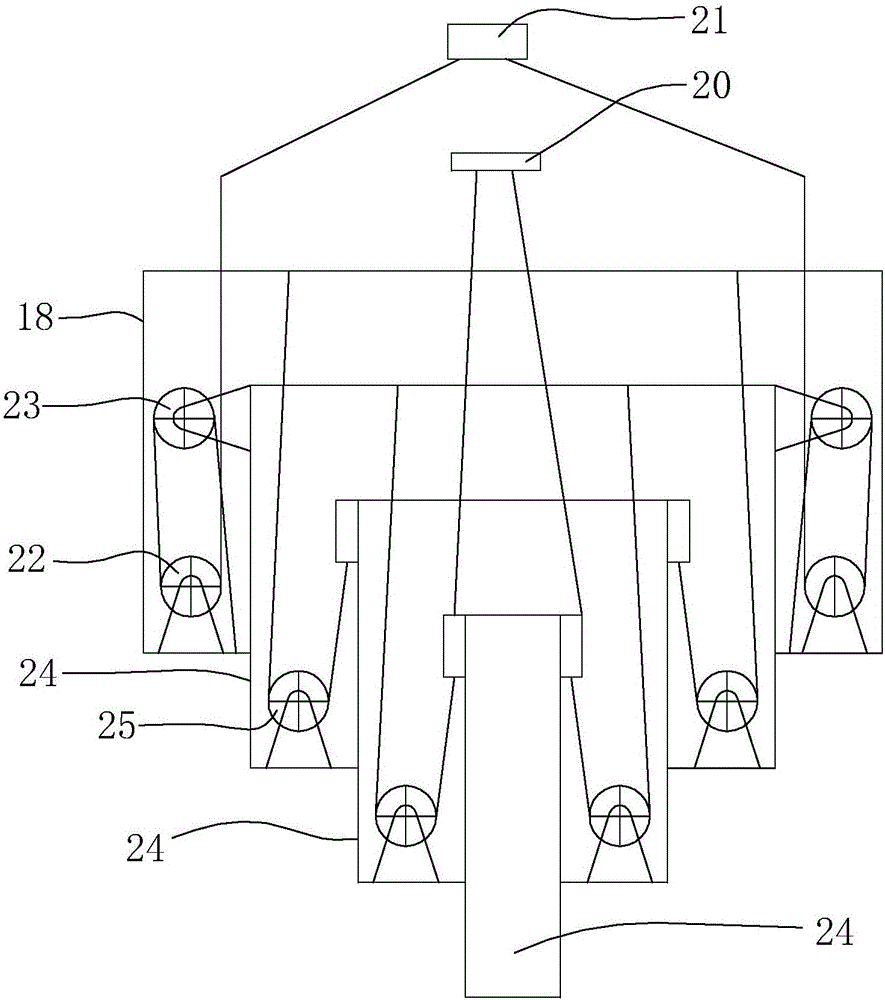

[0052] to combine Image 6 Shown, except the movable drill rod 24 that connects main drill rod 3, all the other movable drill rods 24 bottom inner walls are provided with a movable drill rod guiding mud scraping sleeve 24a, and the structure of movable drilling rod guiding mud scraping sleeve 24a can be compared with The structure of the guide mud scraping sleeve 29 of the mova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com