Two-stroke Engine With Fuel Injection

一种燃料喷射装置、发动机的技术,应用在燃烧发动机、低压燃料喷射、燃料喷射装置等方向,能够解决削弱兼容性、制造成本增加、增加发动机复杂性和尺寸等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

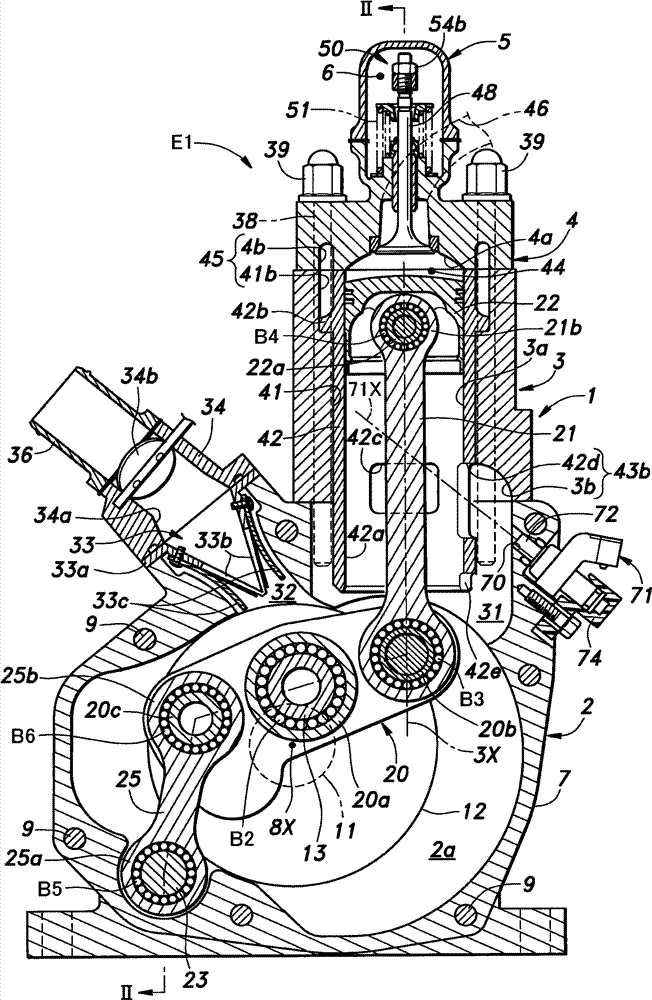

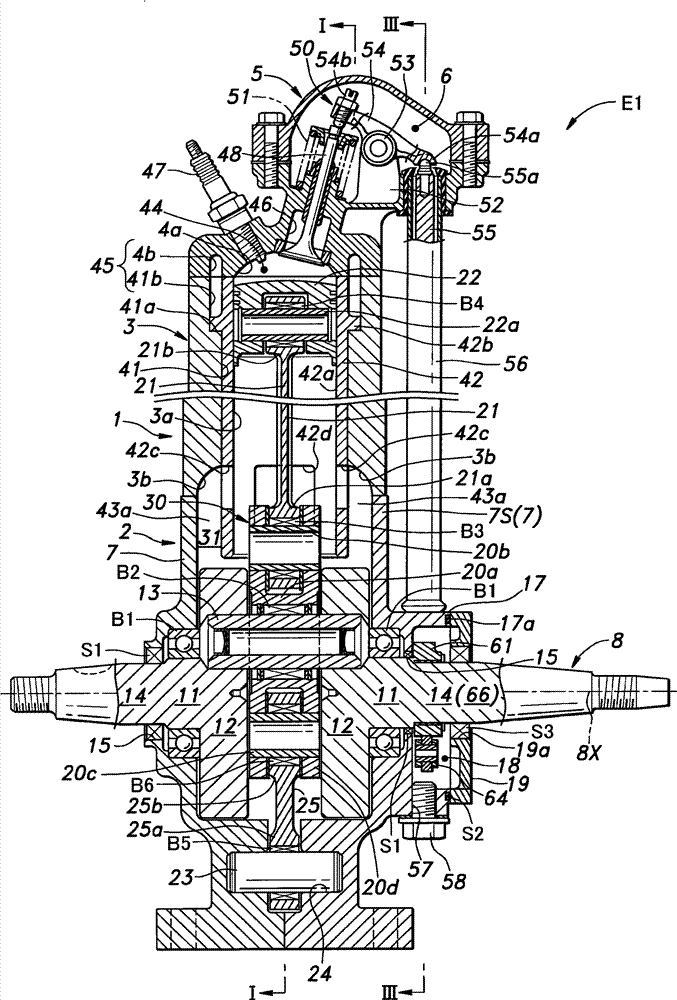

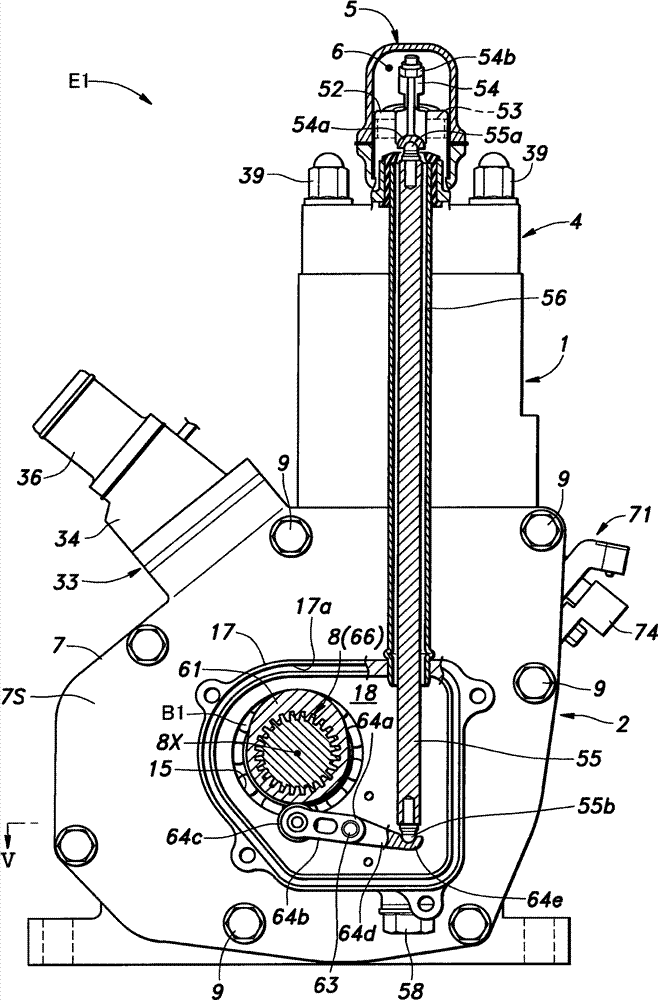

[0024] will be referred to below Figure 1 to Figure 5 A first embodiment of the present invention constituted by a one-cylinder two-stroke engine (engine E1 ) of the unidirectional flow type is described.

[0025] refer to figure 1 and figure 2 , an engine body 1 of an engine E1 is provided with a crankcase 2 defining a crank chamber 2a therein, a cylinder block 3 connected to an upper end of the crankcase 2 and defining a cylinder bore 3a therein, a cylinder head 4 connected to an upper end of the cylinder block 3 and a cylinder head cover 5 attached to the upper end of the cylinder head 4 to define an upper valve chamber 6 in cooperation with the cylinder head 4 .

[0026] Such as figure 2 As best shown, the crankcase 2 consists of two crankcase halves 7 having a parting plane extending perpendicular to the crankshaft axis 8X and joined to each other by seven bolts 9 ( figure 1 and image 3 ). Each crankcase half 7 comprises a side wall 7S provided with an opening t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com