Double tube single action core drilling tool

A core drilling tool and drill bit technology, which is applied in the direction of extracting undisturbed core devices, drill bits, drilling equipment, etc., can solve the problems of failure to meet the requirements of geological exploration, difficulty in obtaining rock cores, etc., and achieve flexible and reliable single-action performance. The effect of engineering quality and long bearing life

Active Publication Date: 2012-08-15

核工业二一六大队

View PDF0 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The core recovery rate is lower than 50%, it is difficult to obtain qualified rock cores that meet the quality requirements, and the geological exploration requirements cannot be met

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

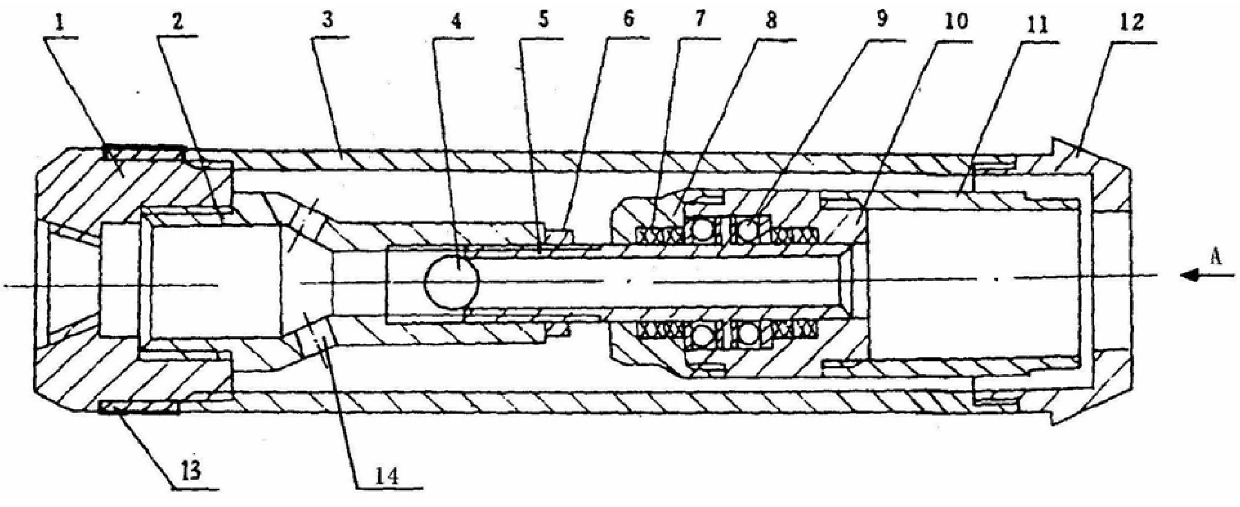

[0015] Below in conjunction with the embodiments and accompanying drawings, the double-tube single-action core drilling tool provided by the present invention will be further described.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

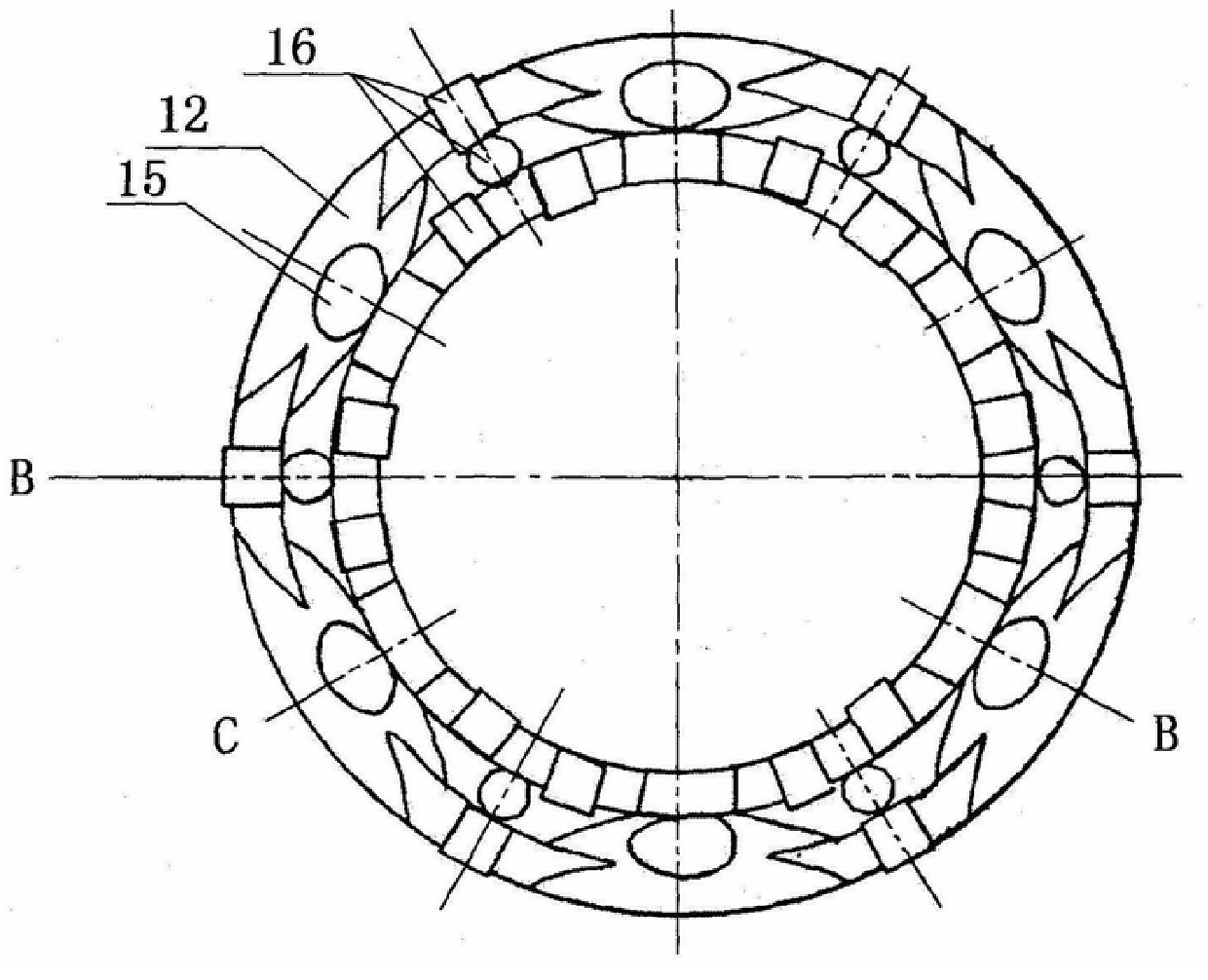

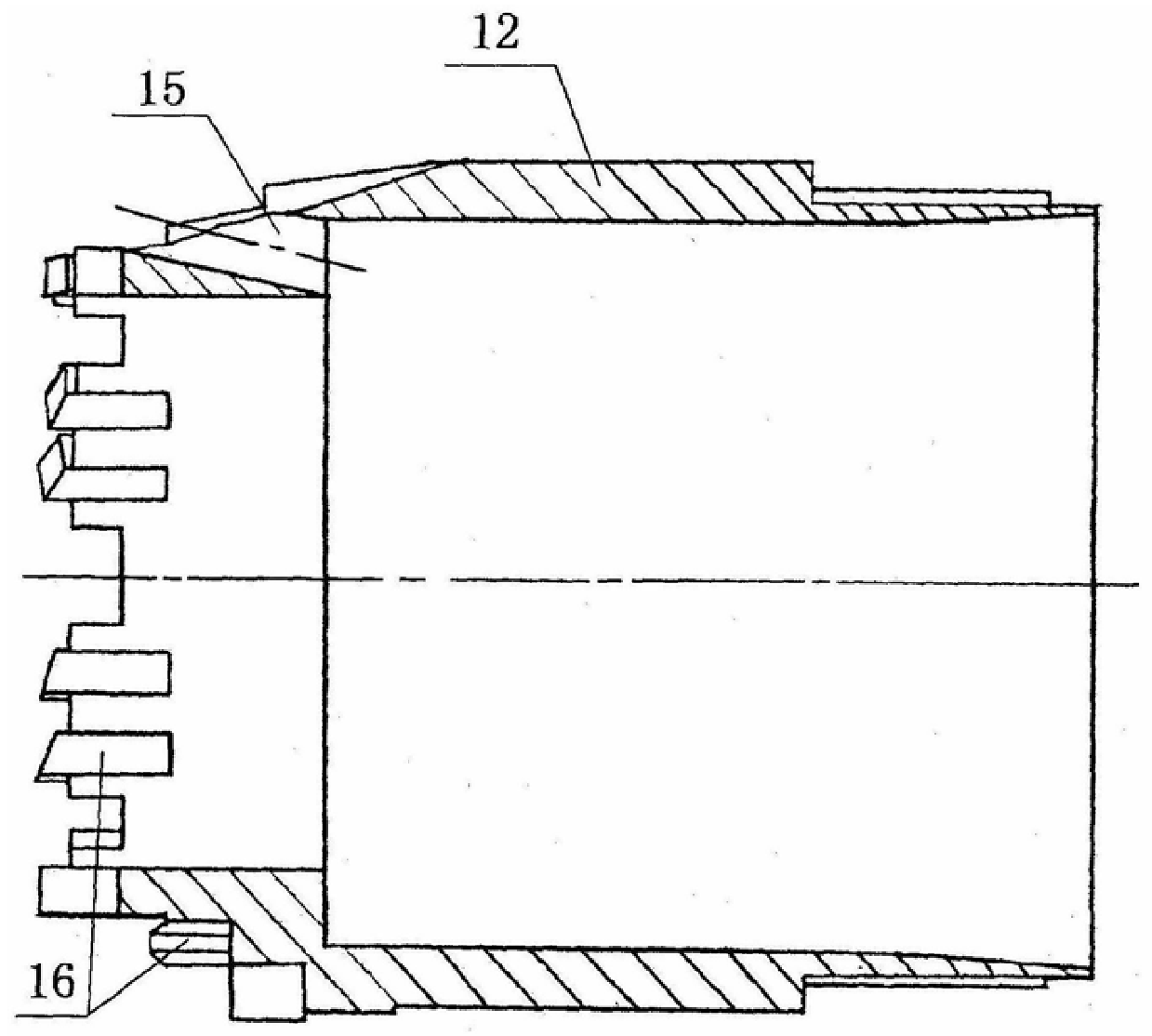

The invention belongs to a drilling tool, and specifically discloses a double-tube single-action core drilling tool. The lip surface of the drill bit is stepped from the inner ring to the outer ring along its radial direction, and the rest of the lip surface of the drill bit is tapered. ; The axis of the water eye and the drill bit intersects in the inner cavity of the drill bit; the connecting end of the cross mandrel and the water distribution joint is provided with a ball-throwing check valve. The bottom lip surface of the drill bit of the present invention adopts a stepped tapered structure, which has a pressing effect on the larger gravel towards the hole wall, avoids the wear and tear of the core by the larger gravel, and has good rotation stability and guiding performance of the drilling tool. It is beneficial to protect the core and prevent the hole from being inclined; after the ball-throwing check valve throws the ball, the flushing fluid flows from the drill pipe through the gap between the inner and outer pipes to the water hole of the side-spray drill bit and then flows to the bottom of the hole, avoiding the impact of the liquid flow on the core in the pipe Direct erosion; the average recovery rate of rock core is increased from 40.30% to 91%, and the high-quality porosity is increased from 17.40% to more than 90%, which meets the requirements of geological prospecting.

Description

Double-tube single-action core drilling tool technical field [0001] The invention belongs to drilling tools, in particular to a double-tube single-action drilling tool. Background technique The crisp sandstone in Yili Basin mainly refers to the middle and lower Jurassic medium-coarse sandstone, pebble-containing sandstone and glutenite, and uranium The interlayer oxidation zone closely related to mineralization develops in it, which is the main target layer of geological prospecting. The sand body structure is loose, in the shape of "bean curd residue", the mud is weakly cemented or has no cementation, and the main components are quartz, feldspar and rock Crumbs, gravel diameter 10-250mm gravel content up to 60-70%. When core drilling in this formation, the core is subjected to external force (mechanical action or liquid action), its natural structure is easily destroyed, and it is easily eroded by the flushing fluid and "dissolved" in the flushing fluid. The heart ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E21B10/02E21B10/48E21B25/00

Inventor 贾中芳张海滢马书义

Owner 核工业二一六大队

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com