Filling pile spiral hoisting slurry drill pipe

A technology of spiral lifting and cast-in-place piles, which is applied in the direction of drill pipes, drill pipes, drilling equipment, etc., can solve the problems of thick slurry and mud blocks that are difficult to discharge from the hole of the pile, increased mud concentration, etc., and achieve the purpose of improving practical value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in more detail below with reference to the accompanying drawings. It should be noted that, these drawings are all in a very simplified form and use inaccurate ratios, and are only used to facilitate and clearly describe the embodiments of the present invention.

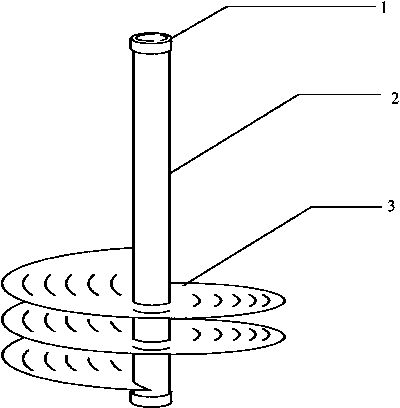

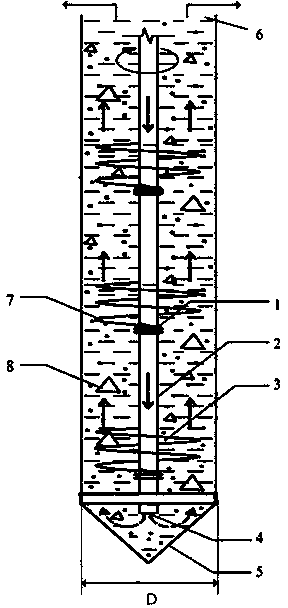

[0016] see figure 1 and figure 2 , the cast-in-place pile auger pipe provided by the present invention includes one or several sections of hollow drill pipe 2 and a drill pipe joint 1 connected with the hollow drill pipe 2. The outer surface of the hollow drill pipe 2 is provided with a helical blade 3, and each section of the hollow drill pipe is provided with a spiral blade 3. The rods 2 are connected through a drill pipe joint 1 , and a spray port 4 is provided at the connection between the first section of the hollow drill rod 2 and the drill bit 5 .

[0017] Wherein, the helical blade 3 is arranged on the lower section of the hollow drill rod 2, and the length of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com